Atomizing Metal Powder Market Size, Share, and Trends Analysis Report

CAGR :

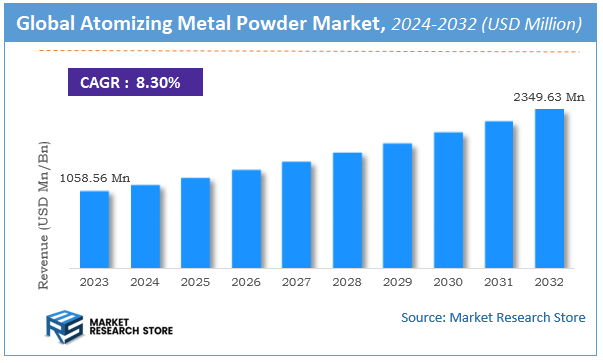

| Market Size 2023 (Base Year) | USD 1058.56 Million |

| Market Size 2032 (Forecast Year) | USD 2349.63 Million |

| CAGR | 8.3% |

| Forecast Period | 2024 - 2032 |

| Historical Period | 2018 - 2023 |

Market Research Store has published a report on the global atomizing metal powder market, estimating its value at USD 1058.56 Million in 2023, with projections indicating it will reach USD 2349.63 Million by the end of 2032. The market is expected to expand at a compound annual growth rate (CAGR) of around 8.3% over the forecast period. The report examines the factors driving market growth, the obstacles that could hinder this expansion, and the opportunities that may emerge in the atomizing metal powder industry. Additionally, it offers a detailed analysis of how these elements will affect demand dynamics and market performance throughout the forecast period.

To Get more Insights, Request a Free Sample

Atomizing Metal Powder Market: Overview

The growth of the atomizing metal powder market is fueled by rising global demand across various industries and applications. The report highlights lucrative opportunities, analyzing cost structures, key segments, emerging trends, regional dynamics, and advancements by leading players to provide comprehensive market insights. The atomizing metal powder market report offers a detailed industry analysis from 2024 to 2032, combining quantitative and qualitative insights. It examines key factors such as pricing, market penetration, GDP impact, industry dynamics, major players, consumer behavior, and socio-economic conditions. Structured into multiple sections, the report provides a comprehensive perspective on the market from all angles.

Key sections of the atomizing metal powder market report include market segments, outlook, competitive landscape, and company profiles. Market Segments offer in-depth details based on Type, Application, End-User, Atomization Method, and other relevant classifications to support strategic marketing initiatives. Market Outlook thoroughly analyzes market trends, growth drivers, restraints, opportunities, challenges, Porter’s Five Forces framework, macroeconomic factors, value chain analysis, and pricing trends shaping the market now and in the future. The Competitive Landscape and Company Profiles section highlights major players, their strategies, and market positioning to guide investment and business decisions. The report also identifies innovation trends, new business opportunities, and investment prospects for the forecast period.

Key Highlights:

- As per the analysis shared by our research analyst, the global atomizing metal powder market is estimated to grow annually at a CAGR of around 8.3% over the forecast period (2024-2032).

- In terms of revenue, the global atomizing metal powder market size was valued at around USD 1058.56 Million in 2023 and is projected to reach USD 2349.63 Million by 2032.

- The market is projected to grow at a significant rate due to Increasing demand in additive manufacturing and powder metallurgy drives this market.

- Based on the Type, the Iron Powder segment is growing at a high rate and will continue to dominate the global market as per industry projections.

- On the basis of Application, the Metallurgy segment is anticipated to command the largest market share.

- In terms of End-User, the Automotive segment is projected to lead the global market.

- By Atomization Method, the Gas Atomization segment is predicted to dominate the global market.

- Based on region, North America is projected to dominate the global market during the forecast period.

Atomizing Metal Powder Market: Report Scope

This report thoroughly analyzes the atomizing metal powder market, exploring its historical trends, current state, and future projections. The market estimates presented result from a robust research methodology, incorporating primary research, secondary sources, and expert opinions. These estimates are influenced by the prevailing market dynamics as well as key economic, social, and political factors. Furthermore, the report considers the impact of regulations, government expenditures, and advancements in research and development on the market. Both positive and negative shifts are evaluated to ensure a comprehensive and accurate market outlook.

| Report Attributes | Report Details |

|---|---|

| Report Name | Atomizing Metal Powder Market |

| Market Size in 2023 | USD 1058.56 Million |

| Market Forecast in 2032 | USD 2349.63 Million |

| Growth Rate | CAGR of 8.3% |

| Number of Pages | 205 |

| Key Companies Covered | Sandvik AB, GKN Powder Metallurgy, Rio Tinto Metal Powders, Höganäs AB, Carpenter Technology, BASF SE, CNPC Powder, Kymera International, American Elements, Pometon SpA |

| Segments Covered | By Type, By Application, By End-User, By Atomization Method, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2023 |

| Forecast Year | 2024 to 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Atomizing Metal Powder Market: Dynamics

The Atomizing Metal Powder market is a rapidly expanding and strategically important segment, driven by advanced manufacturing techniques and the increasing demand for high-performance materials across diverse industries.

Key Growth Drivers:

The phenomenal rise of additive manufacturing (3D printing) is the most significant driver for the atomizing metal powder market. This technology, used extensively in aerospace, automotive, medical, and defense industries, relies heavily on high-quality, spherical, and precisely sized atomized metal powders to produce complex, lightweight, and high-strength components with minimal waste. The increasing adoption of powder metallurgy and metal injection molding (MIM) for manufacturing intricate parts for various applications also fuels demand. Furthermore, the growing focus on lightweighting in the automotive and aerospace sectors to enhance fuel efficiency and performance directly translates to a higher demand for atomized metal powders, especially for specialized alloys. Continuous advancements in atomization technologies, yielding finer, purer, and more uniform powders, further bolster market growth.

Restraints:

The market faces significant restraints primarily due to the high initial capital investment required for establishing and operating atomizing metal powder production facilities. The specialized equipment, inert gas requirements (e.g., argon, nitrogen), and complex infrastructure contribute to substantial upfront costs, which can deter new entrants and smaller manufacturers. Price volatility of raw metals, such as nickel, cobalt, and titanium, directly impacts the production cost of atomized powders, leading to fluctuating prices and affecting profit margins for manufacturers. Concerns related to the safety of handling finely divided metal powders, including their pyrophoric nature and potential for dust cloud explosions, necessitate stringent safety protocols and specialized facilities, adding to operational expenses.

Opportunities:

Significant opportunities lie in the ongoing research and development of new high-performance alloys and specialized powder characteristics tailored for specific additive manufacturing applications and advanced engineering requirements. The development of more energy-efficient atomization processes and improved powder recycling techniques offers strong avenues for reducing production costs and enhancing sustainability. Expanding applications into new and emerging sectors, such as electronics (for conductive inks and heat sinks), advanced coatings, and renewable energy technologies (e.g., fuel cells, batteries), presents substantial untapped market potential. The increasing demand for customized and application-specific metal powders, requiring precise particle size distribution and morphology, also creates lucrative opportunities for specialized manufacturers.

Challenges:

A key challenge is ensuring the consistent quality, purity, and particle size distribution of atomized metal powders across different batches, as even minor variations can significantly impact the performance of the final manufactured part. Managing the high production costs associated with atomization, particularly for very fine or specialized powders, while remaining competitive in the market, is an ongoing hurdle. The technical complexities of optimizing atomization parameters (e.g., nozzle design, gas pressure, molten metal flow) to achieve desired powder characteristics and minimize defects like satellite particles or internal porosity, require continuous R&D. Furthermore, the need for stringent quality control, characterization, and traceability throughout the production process to meet demanding industry standards (e.g., aerospace, medical) adds to the overall operational complexity.

Atomizing Metal Powder Market: Segmentation Insights

The global atomizing metal powder market is segmented based on Type, Application, End-User, Atomization Method, and Region. All the segments of the atomizing metal powder market have been analyzed based on present & future trends and the market is estimated from 2024 to 2032.

Based on Type, the global atomizing metal powder market is divided into Iron Powder, Copper Powder, Aluminum Powder, Zinc Powder, Others.

On the basis of Application, the global atomizing metal powder market is bifurcated into Metallurgy, Additive Manufacturing, Coatings, Electronics, Welding, Others.

In terms of End-User, the global atomizing metal powder market is categorized into Automotive, Aerospace, Industrial Machinery, Electronics, Medical.

Based on Atomization Method, the global atomizing metal powder market is split into Gas Atomization, Water Atomization, Centrifugal Atomization, Others.

Atomizing Metal Powder Market: Regional Insights

The Asia-Pacific (APAC) region dominates the global atomizing metal powder market, accounting for over 45% of market share in 2023, driven by rapid industrialization, strong manufacturing sectors, and increasing demand from automotive, aerospace, and additive manufacturing industries. China is the largest contributor, supported by its massive metal production capabilities and government initiatives promoting advanced manufacturing technologies like 3D printing.

North America and Europe follow, with significant growth in high-performance metal powders for aerospace and medical applications, but APAC's cost-efficient production and expanding end-use industries ensure its continued dominance. The region is projected to grow at a CAGR of around 8–10% (2024–2032), fueled by rising investments in powder metallurgy and additive manufacturing, particularly in China, Japan, and South Korea.

Atomizing Metal Powder Market: Competitive Landscape

The atomizing metal powder market report offers a thorough analysis of both established and emerging players within the market. It includes a detailed list of key companies, categorized based on the types of products they offer and other relevant factors. The report also highlights the market entry year for each player, providing further context for the research analysis.

The "Global Atomizing Metal Powder Market" study offers valuable insights, focusing on the global market landscape, with an emphasis on major industry players such as;

- Sandvik AB

- GKN Powder Metallurgy

- Rio Tinto Metal Powders

- Höganäs AB

- Carpenter Technology

- BASF SE

- CNPC Powder

- Kymera International

- American Elements

- Pometon SpA

The Global Atomizing Metal Powder Market is Segmented as Follows:

By Type

- Iron Powder

- Copper Powder

- Aluminum Powder

- Zinc Powder

- Others

By Application

- Metallurgy

- Additive Manufacturing

- Coatings

- Electronics

- Welding

- Others

By End-User

- Automotive

- Aerospace

- Industrial Machinery

- Electronics

- Medical

By Atomization Method

- Gas Atomization

- Water Atomization

- Centrifugal Atomization

- Others

By Region

- North America

- The U.S.

- Canada

- Mexico

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Australia

- South Korea

- Rest of Asia Pacific

- The Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- Kuwait

- South Africa

- Rest of the Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

Market Evolution

This section evaluates the market position of the product or service by examining its development pathway and competitive dynamics. It provides a detailed overview of the product's growth stages, including the early (historical) phase, the mid-stage, and anticipated future advancements influenced by innovation and emerging technologies.

Porter’s Analysis

Porter’s Five Forces framework offers a strategic lens for assessing competitor behavior and the positioning of key players in the atomizing metal powder industry. This section explores the external factors shaping competitive dynamics and influencing market strategies in the years ahead. The analysis focuses on five critical forces:

- Competitive Rivalry

- Threat of New Entrants

- Threat of Substitutes

- Supplier Bargaining Power

- Buyer Bargaining Power

Value Chain & Market Attractiveness Analysis

The value chain analysis helps businesses optimize operations by mapping the product flow from suppliers to end consumers, identifying opportunities to streamline processes and gain a competitive edge. Segment-wise market attractiveness analysis evaluates key dimensions like product categories, demographics, and regions, assessing growth potential, market size, and profitability. This enables businesses to focus resources on high-potential segments for better ROI and long-term value.

PESTEL Analysis

PESTEL analysis is a powerful tool in market research reports that enhances market understanding by systematically examining the external macro-environmental factors influencing a business or industry. The acronym stands for Political, Economic, Social, Technological, Environmental, and Legal factors. By evaluating these dimensions, PESTEL analysis provides a comprehensive overview of the broader context within which a market operates, helping businesses identify potential opportunities and threats.

- Political factors assess government policies, stability, trade regulations, and political risks that could impact market operations.

- Economic factors examine variables like inflation, exchange rates, economic growth, and consumer spending power to determine market viability.

- Social factors explore cultural trends, demographics, and lifestyle changes that shape consumer behavior and preferences.

- Technological factors evaluate innovation, R&D, and technological advancements affecting product development and operational efficiencies.

- Environmental factors focus on sustainability, climate change impacts, and eco-friendly practices shaping market trends.

- Legal factors address compliance requirements, industry regulations, and intellectual property laws impacting market entry and operations.

Import-Export Analysis & Pricing Analysis

An import-export analysis is vital for market research, revealing global trade dynamics, trends, and opportunities. It examines trade volumes, product categories, and regional competitiveness, offering insights into supply chains and market demand. This section also analyzes past and future pricing trends, helping businesses optimize strategies and enabling consumers to assess product value effectively.

Atomizing Metal Powder Market: Company Profiles

The report identifies key players in the atomizing metal powder market through a competitive landscape and company profiles, evaluating their offerings, financial performance, strategies, and market positioning. It includes a SWOT analysis of the top 3-5 companies, assessing strengths, weaknesses, opportunities, and threats. The competitive landscape highlights rankings, recent activities (mergers, acquisitions, partnerships, product launches), and regional footprints using the Ace matrix. Customization is available to meet client-specific needs.

Regional & Industry Footprint

This section details the geographic reach, sales networks, and market penetration of companies profiled in the atomizing metal powder report, showcasing their operations and distribution across regions. It analyzes the alignment of companies with specific industry verticals, highlighting the industries they serve and the scope of their products and services within those sectors.

Ace Matrix

This section categorizes companies into four distinct groups—Active, Cutting Edge, Innovator, and Emerging—based on their product and business strategies. The evaluation of product strategy focuses on aspects such as the range and depth of offerings, commitment to innovation, product functionalities, and scalability. Key elements like global reach, sector coverage, strategic acquisitions, and long-term growth plans are considered for business strategy. This analysis provides a detailed view of companies' position within the market and highlights their potential for future growth and development.

Research Methodology

The qualitative and quantitative insights for the atomizing metal powder market are derived through a multi-faceted research approach, combining input from subject matter experts, primary research, and secondary data sources. Primary research includes gathering critical information via face-to-face or telephonic interviews, surveys, questionnaires, and feedback from industry professionals, key opinion leaders (KOLs), and customers. Regular interviews with industry experts are conducted to deepen the analysis and reinforce the existing data, ensuring a robust and well-rounded market understanding.

Secondary research for this report was carried out by the Market Research Store team, drawing on a variety of authoritative sources, such as:

- Official company websites, annual reports, financial statements, investor presentations, and SEC filings

- Internal and external proprietary databases, as well as relevant patent and regulatory databases

- Government publications, national statistical databases, and industry-specific market reports

- Media coverage, including news articles, press releases, and webcasts about market participants

- Paid industry databases for detailed market insights

Market Research Store conducted in-depth consultations with various key opinion leaders in the industry, including senior executives from top companies and regional leaders from end-user organizations. This effort aimed to gather critical insights on factors such as the market share of dominant brands in specific countries and regions, along with pricing strategies for products and services.

To determine total sales data, the research team conducted primary interviews across multiple countries with influential stakeholders, including:

- Distributors

- Marketing, Brand, and Product Managers

- Procurement and Production Managers

- Sales and Regional Sales Managers, Country Managers

- Technical Specialists

- C-Level Executives

These subject matter experts, with their extensive industry experience, helped validate and refine the findings. For secondary research, data were sourced from a wide range of materials, including online resources, company annual reports, industry publications, research papers, association reports, and government websites. These various sources provide a comprehensive and well-rounded perspective on the market.

Frequently Asked Questions

Table Of Content

Table of Content 1 Report Overview 1.1 Study Scope 1.2 Key Market Segments 1.3 Regulatory Scenario by Region/Country 1.4 Market Investment Scenario Strategic 1.5 Market Analysis by Type 1.5.1 Global Atomizing Metal Powder Market Share by Type (2020-2026) 1.5.2 Atomizing Copper Powder 1.5.3 Atomizing Iron Powder 1.5.4 Other 1.6 Market by Application 1.6.1 Global Atomizing Metal Powder Market Share by Application (2020-2026) 1.6.2 Metallurgy Industry 1.6.3 Chemical Industry 1.6.4 Electronic Materials 1.6.5 Diamond Tools 1.6.6 Welding 1.6.7 Others 1.7 Atomizing Metal Powder Industry Development Trends under COVID-19 Outbreak 1.7.1 Global COVID-19 Status Overview 1.7.2 Influence of COVID-19 Outbreak on Atomizing Metal Powder Industry Development 2. Global Market Growth Trends 2.1 Industry Trends 2.1.1 SWOT Analysis 2.1.2 Porter’s Five Forces Analysis 2.2 Potential Market and Growth Potential Analysis 2.3 Industry News and Policies by Regions 2.3.1 Industry News 2.3.2 Industry Policies 2.4 Industry Trends Under COVID-19 3 Value Chain of Atomizing Metal Powder Market 3.1 Value Chain Status 3.2 Atomizing Metal Powder Manufacturing Cost Structure Analysis 3.2.1 Production Process Analysis 3.2.2 Manufacturing Cost Structure of Atomizing Metal Powder 3.2.3 Labor Cost of Atomizing Metal Powder 3.2.3.1 Labor Cost of Atomizing Metal Powder Under COVID-19 3.3 Sales and Marketing Model Analysis 3.4 Downstream Major Customer Analysis (by Region) 3.5 Value Chain Status Under COVID-19 4 Players Profiles 4.1 Shanghai CNPC Enterprise 4.1.1 Shanghai CNPC Enterprise Basic Information 4.1.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.1.3 Shanghai CNPC Enterprise Atomizing Metal Powder Market Performance (2015-2020) 4.1.4 Shanghai CNPC Enterprise Business Overview 4.2 BaZhou HongSheng 4.2.1 BaZhou HongSheng Basic Information 4.2.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.2.3 BaZhou HongSheng Atomizing Metal Powder Market Performance (2015-2020) 4.2.4 BaZhou HongSheng Business Overview 4.3 Mitsui Kinzoku 4.3.1 Mitsui Kinzoku Basic Information 4.3.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.3.3 Mitsui Kinzoku Atomizing Metal Powder Market Performance (2015-2020) 4.3.4 Mitsui Kinzoku Business Overview 4.4 CNPC Powder Material 4.4.1 CNPC Powder Material Basic Information 4.4.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.4.3 CNPC Powder Material Atomizing Metal Powder Market Performance (2015-2020) 4.4.4 CNPC Powder Material Business Overview 4.5 Jiande Yitong 4.5.1 Jiande Yitong Basic Information 4.5.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.5.3 Jiande Yitong Atomizing Metal Powder Market Performance (2015-2020) 4.5.4 Jiande Yitong Business Overview 4.6 Kobelco 4.6.1 Kobelco Basic Information 4.6.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.6.3 Kobelco Atomizing Metal Powder Market Performance (2015-2020) 4.6.4 Kobelco Business Overview 4.7 GGP Metal Powder 4.7.1 GGP Metal Powder Basic Information 4.7.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.7.3 GGP Metal Powder Atomizing Metal Powder Market Performance (2015-2020) 4.7.4 GGP Metal Powder Business Overview 4.8 SCHLENK 4.8.1 SCHLENK Basic Information 4.8.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.8.3 SCHLENK Atomizing Metal Powder Market Performance (2015-2020) 4.8.4 SCHLENK Business Overview 4.9 GKN (Hoeganaes) 4.9.1 GKN (Hoeganaes) Basic Information 4.9.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.9.3 GKN (Hoeganaes) Atomizing Metal Powder Market Performance (2015-2020) 4.9.4 GKN (Hoeganaes) Business Overview 4.10 SAFINA Materials 4.10.1 SAFINA Materials Basic Information 4.10.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.10.3 SAFINA Materials Atomizing Metal Powder Market Performance (2015-2020) 4.10.4 SAFINA Materials Business Overview 4.11 Pound Met 4.11.1 Pound Met Basic Information 4.11.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.11.3 Pound Met Atomizing Metal Powder Market Performance (2015-2020) 4.11.4 Pound Met Business Overview 4.12 Laiwu Iron&Steel Group 4.12.1 Laiwu Iron&Steel Group Basic Information 4.12.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.12.3 Laiwu Iron&Steel Group Atomizing Metal Powder Market Performance (2015-2020) 4.12.4 Laiwu Iron&Steel Group Business Overview 4.13 Tongling Guochuan Electronic Material 4.13.1 Tongling Guochuan Electronic Material Basic Information 4.13.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.13.3 Tongling Guochuan Electronic Material Atomizing Metal Powder Market Performance (2015-2020) 4.13.4 Tongling Guochuan Electronic Material Business Overview 4.14 Kymera International 4.14.1 Kymera International Basic Information 4.14.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.14.3 Kymera International Atomizing Metal Powder Market Performance (2015-2020) 4.14.4 Kymera International Business Overview 4.15 Changsung Corporation 4.15.1 Changsung Corporation Basic Information 4.15.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.15.3 Changsung Corporation Atomizing Metal Powder Market Performance (2015-2020) 4.15.4 Changsung Corporation Business Overview 4.16 Anhui Xujing Powder New-material 4.16.1 Anhui Xujing Powder New-material Basic Information 4.16.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.16.3 Anhui Xujing Powder New-material Atomizing Metal Powder Market Performance (2015-2020) 4.16.4 Anhui Xujing Powder New-material Business Overview 4.17 Hoganas 4.17.1 Hoganas Basic Information 4.17.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.17.3 Hoganas Atomizing Metal Powder Market Performance (2015-2020) 4.17.4 Hoganas Business Overview 4.18 Gripm Advanced Materials 4.18.1 Gripm Advanced Materials Basic Information 4.18.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.18.3 Gripm Advanced Materials Atomizing Metal Powder Market Performance (2015-2020) 4.18.4 Gripm Advanced Materials Business Overview 4.19 Pometon 4.19.1 Pometon Basic Information 4.19.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.19.3 Pometon Atomizing Metal Powder Market Performance (2015-2020) 4.19.4 Pometon Business Overview 4.20 Rio Tinto Metal Powders 4.20.1 Rio Tinto Metal Powders Basic Information 4.20.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.20.3 Rio Tinto Metal Powders Atomizing Metal Powder Market Performance (2015-2020) 4.20.4 Rio Tinto Metal Powders Business Overview 4.21 Chemet 4.21.1 Chemet Basic Information 4.21.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.21.3 Chemet Atomizing Metal Powder Market Performance (2015-2020) 4.21.4 Chemet Business Overview 4.22 SMM Group 4.22.1 SMM Group Basic Information 4.22.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.22.3 SMM Group Atomizing Metal Powder Market Performance (2015-2020) 4.22.4 SMM Group Business Overview 4.23 Fukuda Metal Foil & Powder 4.23.1 Fukuda Metal Foil & Powder Basic Information 4.23.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.23.3 Fukuda Metal Foil & Powder Atomizing Metal Powder Market Performance (2015-2020) 4.23.4 Fukuda Metal Foil & Powder Business Overview 4.24 JFE 4.24.1 JFE Basic Information 4.24.2 Atomizing Metal Powder Product Profiles, Application and Specification 4.24.3 JFE Atomizing Metal Powder Market Performance (2015-2020) 4.24.4 JFE Business Overview 5 Global Atomizing Metal Powder Market Analysis by Regions 5.1 Global Atomizing Metal Powder Sales, Revenue and Market Share by Regions 5.1.1 Global Atomizing Metal Powder Sales by Regions (2015-2020) 5.1.2 Global Atomizing Metal Powder Revenue by Regions (2015-2020) 5.2 North America Atomizing Metal Powder Sales and Growth Rate (2015-2020) 5.3 Europe Atomizing Metal Powder Sales and Growth Rate (2015-2020) 5.4 Asia-Pacific Atomizing Metal Powder Sales and Growth Rate (2015-2020) 5.5 Middle East and Africa Atomizing Metal Powder Sales and Growth Rate (2015-2020) 5.6 South America Atomizing Metal Powder Sales and Growth Rate (2015-2020) 6 North America Atomizing Metal Powder Market Analysis by Countries 6.1 North America Atomizing Metal Powder Sales, Revenue and Market Share by Countries 6.1.1 North America Atomizing Metal Powder Sales by Countries (2015-2020) 6.1.2 North America Atomizing Metal Powder Revenue by Countries (2015-2020) 6.1.3 North America Atomizing Metal Powder Market Under COVID-19 6.2 United States Atomizing Metal Powder Sales and Growth Rate (2015-2020) 6.2.1 United States Atomizing Metal Powder Market Under COVID-19 6.3 Canada Atomizing Metal Powder Sales and Growth Rate (2015-2020) 6.4 Mexico Atomizing Metal Powder Sales and Growth Rate (2015-2020) 7 Europe Atomizing Metal Powder Market Analysis by Countries 7.1 Europe Atomizing Metal Powder Sales, Revenue and Market Share by Countries 7.1.1 Europe Atomizing Metal Powder Sales by Countries (2015-2020) 7.1.2 Europe Atomizing Metal Powder Revenue by Countries (2015-2020) 7.1.3 Europe Atomizing Metal Powder Market Under COVID-19 7.2 Germany Atomizing Metal Powder Sales and Growth Rate (2015-2020) 7.2.1 Germany Atomizing Metal Powder Market Under COVID-19 7.3 UK Atomizing Metal Powder Sales and Growth Rate (2015-2020) 7.3.1 UK Atomizing Metal Powder Market Under COVID-19 7.4 France Atomizing Metal Powder Sales and Growth Rate (2015-2020) 7.4.1 France Atomizing Metal Powder Market Under COVID-19 7.5 Italy Atomizing Metal Powder Sales and Growth Rate (2015-2020) 7.5.1 Italy Atomizing Metal Powder Market Under COVID-19 7.6 Spain Atomizing Metal Powder Sales and Growth Rate (2015-2020) 7.6.1 Spain Atomizing Metal Powder Market Under COVID-19 7.7 Russia Atomizing Metal Powder Sales and Growth Rate (2015-2020) 7.7.1 Russia Atomizing Metal Powder Market Under COVID-19 8 Asia-Pacific Atomizing Metal Powder Market Analysis by Countries 8.1 Asia-Pacific Atomizing Metal Powder Sales, Revenue and Market Share by Countries 8.1.1 Asia-Pacific Atomizing Metal Powder Sales by Countries (2015-2020) 8.1.2 Asia-Pacific Atomizing Metal Powder Revenue by Countries (2015-2020) 8.1.3 Asia-Pacific Atomizing Metal Powder Market Under COVID-19 8.2 China Atomizing Metal Powder Sales and Growth Rate (2015-2020) 8.2.1 China Atomizing Metal Powder Market Under COVID-19 8.3 Japan Atomizing Metal Powder Sales and Growth Rate (2015-2020) 8.3.1 Japan Atomizing Metal Powder Market Under COVID-19 8.4 South Korea Atomizing Metal Powder Sales and Growth Rate (2015-2020) 8.4.1 South Korea Atomizing Metal Powder Market Under COVID-19 8.5 Australia Atomizing Metal Powder Sales and Growth Rate (2015-2020) 8.6 India Atomizing Metal Powder Sales and Growth Rate (2015-2020) 8.6.1 India Atomizing Metal Powder Market Under COVID-19 8.7 Southeast Asia Atomizing Metal Powder Sales and Growth Rate (2015-2020) 8.7.1 Southeast Asia Atomizing Metal Powder Market Under COVID-19 9 Middle East and Africa Atomizing Metal Powder Market Analysis by Countries 9.1 Middle East and Africa Atomizing Metal Powder Sales, Revenue and Market Share by Countries 9.1.1 Middle East and Africa Atomizing Metal Powder Sales by Countries (2015-2020) 9.1.2 Middle East and Africa Atomizing Metal Powder Revenue by Countries (2015-2020) 9.1.3 Middle East and Africa Atomizing Metal Powder Market Under COVID-19 9.2 Saudi Arabia Atomizing Metal Powder Sales and Growth Rate (2015-2020) 9.3 UAE Atomizing Metal Powder Sales and Growth Rate (2015-2020) 9.4 Egypt Atomizing Metal Powder Sales and Growth Rate (2015-2020) 9.5 Nigeria Atomizing Metal Powder Sales and Growth Rate (2015-2020) 9.6 South Africa Atomizing Metal Powder Sales and Growth Rate (2015-2020) 10 South America Atomizing Metal Powder Market Analysis by Countries 10.1 South America Atomizing Metal Powder Sales, Revenue and Market Share by Countries 10.1.1 South America Atomizing Metal Powder Sales by Countries (2015-2020) 10.1.2 South America Atomizing Metal Powder Revenue by Countries (2015-2020) 10.1.3 South America Atomizing Metal Powder Market Under COVID-19 10.2 Brazil Atomizing Metal Powder Sales and Growth Rate (2015-2020) 10.2.1 Brazil Atomizing Metal Powder Market Under COVID-19 10.3 Argentina Atomizing Metal Powder Sales and Growth Rate (2015-2020) 10.4 Columbia Atomizing Metal Powder Sales and Growth Rate (2015-2020) 10.5 Chile Atomizing Metal Powder Sales and Growth Rate (2015-2020) 11 Global Atomizing Metal Powder Market Segment by Types 11.1 Global Atomizing Metal Powder Sales, Revenue and Market Share by Types (2015-2020) 11.1.1 Global Atomizing Metal Powder Sales and Market Share by Types (2015-2020) 11.1.2 Global Atomizing Metal Powder Revenue and Market Share by Types (2015-2020) 11.2 Atomizing Copper Powder Sales and Price (2015-2020) 11.3 Atomizing Iron Powder Sales and Price (2015-2020) 11.4 Other Sales and Price (2015-2020) 12 Global Atomizing Metal Powder Market Segment by Applications 12.1 Global Atomizing Metal Powder Sales, Revenue and Market Share by Applications (2015-2020) 12.1.1 Global Atomizing Metal Powder Sales and Market Share by Applications (2015-2020) 12.1.2 Global Atomizing Metal Powder Revenue and Market Share by Applications (2015-2020) 12.2 Metallurgy Industry Sales, Revenue and Growth Rate (2015-2020) 12.3 Chemical Industry Sales, Revenue and Growth Rate (2015-2020) 12.4 Electronic Materials Sales, Revenue and Growth Rate (2015-2020) 12.5 Diamond Tools Sales, Revenue and Growth Rate (2015-2020) 12.6 Welding Sales, Revenue and Growth Rate (2015-2020) 12.7 Others Sales, Revenue and Growth Rate (2015-2020) 13 Atomizing Metal Powder Market Forecast by Regions (2020-2026) 13.1 Global Atomizing Metal Powder Sales, Revenue and Growth Rate (2020-2026) 13.2 Atomizing Metal Powder Market Forecast by Regions (2020-2026) 13.2.1 North America Atomizing Metal Powder Market Forecast (2020-2026) 13.2.2 Europe Atomizing Metal Powder Market Forecast (2020-2026) 13.2.3 Asia-Pacific Atomizing Metal Powder Market Forecast (2020-2026) 13.2.4 Middle East and Africa Atomizing Metal Powder Market Forecast (2020-2026) 13.2.5 South America Atomizing Metal Powder Market Forecast (2020-2026) 13.3 Atomizing Metal Powder Market Forecast by Types (2020-2026) 13.4 Atomizing Metal Powder Market Forecast by Applications (2020-2026) 13.5 Atomizing Metal Powder Market Forecast Under COVID-19 14 Appendix 14.1 Methodology 14.2 Research Data Source

Inquiry For Buying

Atomizing Metal Powder

Request Sample

Atomizing Metal Powder