CO2 Laser Coding and Marking Equipment Market Size, Share, and Trends Analysis Report

CAGR :

| Market Size 2023 (Base Year) | USD 3.06 Billion |

| Market Size 2032 (Forecast Year) | USD 6.21 Billion |

| CAGR | 8.2% |

| Forecast Period | 2024 - 2032 |

| Historical Period | 2018 - 2023 |

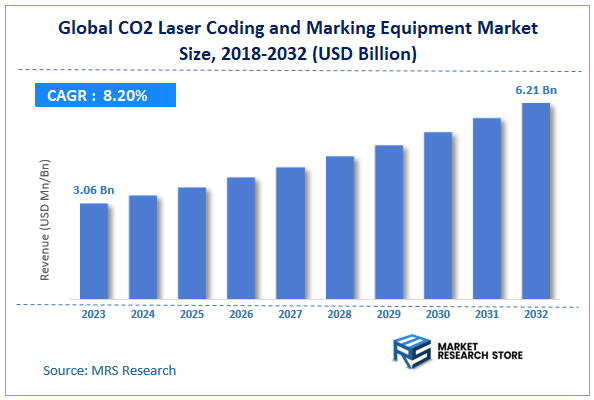

According to Market Research Store, the global CO2 laser coding and marking equipment market size was valued at around USD 3.06 billion in 2023 and is estimated to reach USD 6.21 billion by 2032, to register a CAGR of approximately 8.20% in terms of revenue during the forecast period 2024-2032.

To Get more Insights, Request a Free Sample

The CO2 laser coding and marking equipment report provides a comprehensive analysis of the market, including its size, share, growth trends, revenue details, and other crucial information regarding the target market. It also covers the drivers, restraints, opportunities, and challenges till 2032.

Global CO2 Laser Coding and Marking Equipment Market: Overview

CO₂ laser coding and marking equipment utilizes carbon dioxide lasers to create high-quality markings on various substrates, including plastics, wood, glass, ceramics, and metals. The technology operates by emitting a focused beam of light that interacts with the surface of the material, resulting in a permanent etching or engraving.

This process is highly precise, allowing for intricate designs, logos, barcodes, and serial numbers to be marked with exceptional clarity. CO₂ lasers are particularly valued for their versatility and ability to produce high-contrast markings without the need for inks or solvents, making them ideal for industries such as packaging, pharmaceuticals, food and beverage, and electronics.

Key Highlights

- The CO2 laser coding and marking equipment market is anticipated to grow at a CAGR of 8.20% during the forecast period.

- The global CO2 laser coding and marking equipment market was estimated to be worth approximately USD 3.06 billion in 2023 and is projected to reach a value of USD 6.21 billion by 2032.

- The growth of the CO2 laser coding and marking equipment market is being driven by increasing demand for automation and efficiency in manufacturing processes.

- Based on the type, the scanning marking segment is growing at a high rate and is projected to dominate the market.

- On the basis of application, the electronics and microelectronics segment is projected to swipe the largest market share.

- By region, North America is expected to dominate the global market during the forecast period.

CO2 Laser Coding and Marking Equipment Market: Dynamics

Key Growth Drivers:

- Increasing Demand for Product Traceability and Authentication: The need for robust product tracking and authentication systems across industries like pharmaceuticals, automotive, and electronics is driving the adoption of CO2 laser marking solutions.

- Rising Focus on Product Quality and Safety: CO2 laser marking offers precise and permanent marking, ensuring product quality and safety standards are met.

- Growing Automation in Manufacturing Processes: Integration of CO2 laser marking systems into automated production lines enhances efficiency and reduces labor costs.

- Versatility of CO2 Laser Technology: CO2 lasers can mark on a wide range of materials, including plastics, metals, and ceramics, making them suitable for diverse applications.

Restraints:

- High Initial Investment Costs: The initial investment in CO2 laser marking equipment can be significant, which may deter smaller businesses.

- Complex Maintenance Requirements: CO2 lasers require specialized maintenance and calibration, which can increase operational costs.

- Potential Safety Concerns: Improper handling of CO2 lasers can pose safety risks to operators.

Opportunities:

- Emerging Markets: Expanding into emerging markets with growing manufacturing sectors presents significant opportunities for CO2 laser marking equipment manufacturers.

- Advancements in Laser Technology: Continuous advancements in laser technology, such as higher power and faster marking speeds, will open up new applications and markets.

- Integration with Industry 4.0: The integration of CO2 laser marking systems with Industry 4.0 technologies, such as IoT and AI, will enhance productivity and data-driven decision-making.

Challenges:

- Intense Competition: The market is highly competitive, with numerous established players and emerging competitors.

- Economic Fluctuations: Economic downturns can impact demand for capital-intensive equipment like CO2 laser marking systems.

- Regulatory Compliance: Adherence to stringent safety and environmental regulations can increase costs and complexity for manufacturers.

CO2 Laser Coding and Marking Equipment Market: Segmentation Insights

The global CO2 laser coding and marking equipment market is divided by type, application, and region.

Segmentation Insights by Type

Based on type, the global CO2 laser coding and marking equipment market is divided into mask marking, array marking, and scanning marking.

In the CO2 laser coding and marking equipment market, scanning marking stands as the most dominant segment. Scanning marking employs galvanometer-based systems to direct the laser beam over a material, allowing for fast and precise marking, which makes it particularly popular in industries with high production volumes, such as food and beverage, electronics, and packaging.

This segment is favored due to its speed, flexibility, and ability to achieve intricate designs and patterns on various materials, including metals, plastics, and paper. Scanning marking is highly adaptable to different production needs and can handle large-scale operations, which contributes to its market dominance.

The array marking segment follows, leveraging a matrix of lasers or light sources to mark multiple products simultaneously. This method is efficient for bulk marking and is often employed in applications requiring uniform marking on products with similar dimensions.

Array marking is particularly useful in batch processing for the manufacturing and automotive industries, where consistency and efficiency are paramount. The simultaneous marking capability of array marking ensures cost savings and high productivity, making it a popular choice for standardized marking tasks.

Lastly, mask marking is used in more specialized applications. This segment employs a pre-defined stencil or mask through which the laser beam passes, creating markings in specific shapes or patterns.

Although less flexible than scanning or array marking, mask marking is valued for high-resolution marking requirements, typically on smaller components in sectors like electronics and medical devices. Its precision is ideal for intricate patterns that require detailed control, although its limited scalability compared to scanning or array marking keeps its usage more niche.

Segmentation Insights by Application

On the basis of application, the global CO2 laser coding and marking equipment market is bifurcated into automotive, aerospace, machine tool, electronics & microelectronics, medical, and others.

In the CO2 laser coding and marking equipment market, the electronics and microelectronics segment leads in application demand. This sector values CO2 laser marking for its precision, speed, and ability to mark on delicate components like circuit boards, semiconductor materials, and microchips without causing damage.

The electronics industry relies heavily on CO2 lasers for marking serial numbers, logos, and batch codes on small-scale components, making it the dominant segment due to its stringent marking needs and high production volumes.

Following closely is the automotive sector, where CO2 laser coding is essential for traceability and quality assurance. This application focuses on marking various parts, such as engine components, chassis, and dashboard elements, with information like serial numbers, production dates, and barcodes. The automotive industry’s need for durability in markings, combined with the demand for non-contact, permanent coding, makes CO2 laser technology an ideal choice. The ability to withstand harsh conditions in automotive environments further enhances the suitability of CO2 lasers.

The medical application segment also holds significant market presence. In this sector, CO2 laser marking is used on medical devices, surgical tools, and implants for permanent identification, batch tracking, and regulatory compliance. The precision and reliability of CO2 lasers in marking sensitive equipment without compromising integrity are critical in the medical industry. This technology is widely employed due to strict regulatory standards for traceability and patient safety.

Aerospace applications also utilize CO2 laser marking for permanent identification on aircraft components, where durability and traceability are paramount. Laser marking in this sector is often applied to mark essential information on parts exposed to extreme temperatures and environmental conditions. The aerospace industry's stringent safety standards and the need for reliable marking solutions contribute to the consistent demand for CO2 laser marking.

In the machine tool segment, CO2 laser equipment is used to mark heavy machinery parts, tools, and industrial components with brand logos, serial numbers, and other identifiers. The ability to perform consistent, durable markings on various materials like metals and composites makes CO2 laser marking ideal for this application.

CO2 Laser Coding and Marking Equipment Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | CO2 Laser Coding and Marking Equipment Market |

| Market Size in 2023 | USD 3.06 Billion |

| USD 6.21 Billion | |

| Growth Rate | CAGR of 8.20% |

| Number of Pages | 222 |

| Key Companies Covered | Han's Laser, Trumpf, Telesis, Danaher, Brother, Hitachi, Dover, Macsa, SATO, Gravotech, Trotec, Rofin, TYKMA Electrox, REA JET, ITW, SUNINE, KGK, Matthews, Control print, KBA-Metronic, and others. |

| Segments Covered | By Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

CO2 Laser Coding and Marking Equipment Market: Regional Insights

- North America is expected to dominates the global market

North America leads the CO2 laser coding and marking equipment market due to the region’s high adoption of advanced industrial automation technologies and strong presence of manufacturing industries, especially in sectors like food and beverage, pharmaceuticals, and electronics. The demand for efficient marking solutions for regulatory compliance and product traceability is a significant driver.

Furthermore, ongoing innovation in manufacturing processes and investments in industrial automation by companies in the U.S. and Canada have further bolstered the market's growth.

Europe follows closely, driven by strict regulatory frameworks for product identification and traceability. The region’s focus on sustainability also contributes to growth, as CO2 laser systems offer eco-friendly marking solutions without consumables like ink or chemicals. Germany, Italy, and France are key contributors due to their robust manufacturing sectors and adoption of Industry 4.0. Additionally, the automotive and electronics industries in these countries demand precise and permanent marking solutions, fueling the market’s expansion.

Asia-Pacific ranks as a significant growth area for CO2 laser coding and marking equipment, primarily fueled by rapid industrialization and increased production activities in countries like China, Japan, and South Korea. This region is experiencing a surge in the adoption of laser marking solutions, driven by the expansion of the electronics, automotive, and packaging industries. Government initiatives supporting manufacturing innovation also encourage more businesses to adopt advanced coding technologies to enhance productivity and meet export quality standards.

In Latin America, the market for CO2 laser coding and marking equipment is growing steadily, with Brazil and Mexico as key players. The region’s food and beverage and pharmaceutical sectors are increasingly utilizing laser marking technologies for product identification, compliance, and traceability. While the market faces some challenges, including economic fluctuations, an increase in the region’s manufacturing output and investments in infrastructure positively influence demand for advanced coding solutions.

The Middle East and Africa represent a developing market for CO2 laser coding and marking equipment. Growth in this region is supported by expanding industries like packaging, food and beverage, and construction. Countries such as the UAE and Saudi Arabia are gradually adopting laser marking systems to comply with traceability regulations and improve production efficiency.

However, limited industrial infrastructure in some parts of Africa may restrain growth, though government initiatives and foreign investments aim to bolster regional manufacturing capabilities.

CO2 Laser Coding and Marking Equipment Market: Competitive Landscape

The report provides an in-depth analysis of companies operating in the CO2 laser coding and marking equipment market, including their geographic presence, business strategies, product offerings, market share, and recent developments. This analysis helps to understand market competition.

Some of the major players in the global CO2 laser coding and marking equipment market include:

- Han's Laser

- Trumpf

- Telesis

- Danaher

- Brother

- Hitachi

- Dover

- Macsa

- SATO

- Gravotech

- Trotec

- Rofin

- TYKMA Electrox

- REA JET

- ITW

- SUNINE

- KGK

- Matthews

- Control print

- KBA-Metronic

The global CO2 laser coding and marking equipment market is segmented as follows:

By Type

- Mask Marking

- Array Marking

- Scanning Marking

By Application

- Automotive

- Aerospace

- Machine Tool

- Electronics & Microelectronics

- Medical

- Others

By Region

- North America

- U.S.

- Canada

- Europe

- U.K.

- France

- Germany

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia Pacific

- Latin America

- Brazil

- Rest of Latin America

- The Middle East and Africa

- GCC Countries

- South Africa

- Rest of Middle East Africa

Frequently Asked Questions

Based on statistics from the Market Research Store, the global CO2 laser coding and marking equipment market size was projected at approximately US$ 3.06 billion in 2023. Projections indicate that the market is expected to reach around US$ 6.21 billion in revenue by 2032.

The global CO2 laser coding and marking equipment market is expected to grow at a Compound Annual Growth Rate (CAGR) of around 8.20% during the forecast period from 2024 to 2032.

North America is expected to dominate the global CO2 laser coding and marking equipment market.

Significant factors driving the global CO₂ laser coding and marking equipment market include the increasing demand for efficient and accurate product labeling due to stringent regulatory requirements, the need for enhanced traceability and brand protection, and advancements in laser technology that improve system affordability and versatility.

Some of the prominent players operating in the global CO2 laser coding and marking equipment market are; Han's Laser, Trumpf, Telesis, Danaher, Brother, Hitachi, Dover, Macsa, SATO, Gravotech, Trotec, Rofin, TYKMA Electrox, REA JET, ITW, SUNINE, KGK, Matthews, Control print, KBA-Metronic, and others.

Table Of Content

Inquiry For Buying

CO2 Laser Coding and Marking Equipment

Request Sample

CO2 Laser Coding and Marking Equipment