Conveyor Monitoring Market Size, Share, and Trends Analysis Report

CAGR :

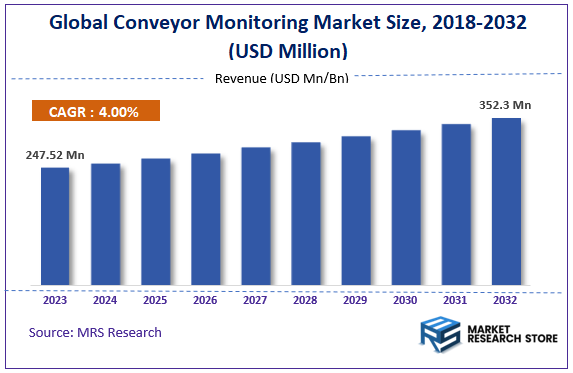

| Market Size 2023 (Base Year) | USD 247.52 Million |

| Market Size 2032 (Forecast Year) | USD 352.3 Million |

| CAGR | 4% |

| Forecast Period | 2024 - 2032 |

| Historical Period | 2018 - 2023 |

According to Market Research Store, the global conveyor monitoring market size was valued at around USD 247.52 million in 2023 and is estimated to reach USD 352.3 million by 2032, to register a CAGR of approximately 4% in terms of revenue during the forecast period 2024-2032.

To Get more Insights, Request a Free Sample

The conveyor monitoring report provides a comprehensive analysis of the market, including its size, share, growth trends, revenue details, and other crucial information regarding the target market. It also covers the drivers, restraints, opportunities, and challenges till 2032.

Global Conveyor Monitoring Market: Overview

The Conveyor Monitoring Market focuses on systems and solutions used to monitor, control, and optimize conveyor belts and material handling systems across industries like manufacturing, mining, logistics, and food processing. Conveyor monitoring solutions typically include sensors, software, and control systems that track the performance, safety, and maintenance needs of conveyor systems.

These systems can detect issues such as misalignment, wear and tear, motor failures, and material blockages in real-time, helping operators prevent breakdowns, reduce downtime, and improve overall operational efficiency. Features like predictive maintenance, vibration analysis, and condition monitoring are common in these systems, allowing businesses to optimize their conveyor operations.

The growth of the conveyor monitoring market is primarily driven by the increasing need for automation, real-time monitoring, and predictive maintenance across industries. As companies look to enhance productivity and reduce operational costs, the demand for conveyor monitoring solutions has surged.

Additionally, the rise of Industry 4.0 and the Industrial Internet of Things (IIoT) has accelerated the adoption of connected devices and smart sensors for conveyor systems, enabling remote monitoring, data analysis, and real-time decision-making. These technologies help companies avoid costly downtime, improve system reliability, and extend the lifespan of conveyor equipment.

Key Highlights

- The conveyor monitoring market is anticipated to grow at a CAGR of 4% during the forecast period.

- The global conveyor monitoring market was estimated to be worth approximately USD 247.52 million in 2023 and is projected to reach a value of USD 352.3 million by 2032.

- The growth of the conveyor monitoring market is being driven by the increasing focus on automation and efficiency in various industries, such as manufacturing and mining, is a primary driver.

- Based on the product, the heavy conveyor monitoring segment is growing at a high rate and is projected to dominate the market.

- On the basis of application, the mining industry segment is projected to swipe the largest market share.

- By region, North America is expected to dominate the global market during the forecast period.

Conveyor Monitoring Market: Dynamics

Key Growth Drivers

- Increasing Focus on Predictive Maintenance: The growing emphasis on predictive maintenance strategies to reduce downtime and optimize operational efficiency is driving the demand for conveyor monitoring systems.

- Rising Demand for Automation: The increasing adoption of automation technologies in various industries, including manufacturing, mining, and logistics, is boosting the need for conveyor monitoring solutions.

- Stringent Safety Regulations: Stricter safety regulations and standards are compelling industries to implement robust monitoring systems to prevent accidents and ensure worker safety.

- Advancements in Sensor Technology: The development of advanced sensors, such as vibration sensors, temperature sensors, and acoustic sensors, is enabling more precise and reliable monitoring of conveyor systems.

Restraints

- High Initial Investment: The initial cost of implementing a conveyor monitoring system, including hardware, software, and installation, can be significant.

- Complex Installation and Maintenance: Installing and maintaining conveyor monitoring systems requires specialized expertise, which can be challenging and costly.

- Data Security Concerns: The increasing reliance on data analytics and cloud-based solutions raises concerns about data security and privacy.

- Economic Fluctuations: Economic downturns can impact capital expenditure budgets, delaying investments in new technologies like conveyor monitoring systems.

Opportunities

- Integration with IoT and AI: Integrating conveyor monitoring systems with IoT devices and AI-powered analytics can enable real-time monitoring, predictive maintenance, and optimized operations.

- Industry-Specific Solutions: Developing customized solutions for specific industries, such as mining, manufacturing, and logistics, can cater to unique needs and challenges.

- Remote Monitoring and Control: Cloud-based monitoring platforms enable remote access and control of conveyor systems, improving operational efficiency and reducing downtime.

- Emerging Markets: Expanding into emerging markets with growing industrialization and infrastructure development can provide significant growth opportunities.

Challenges

- Data Quality and Reliability: Ensuring the accuracy and reliability of data collected from conveyor monitoring systems is crucial for effective decision-making.

- Cybersecurity Threats: Protecting conveyor monitoring systems from cyberattacks is essential to safeguard operations and prevent data breaches.

- Interoperability and Standardization: Ensuring interoperability between different conveyor monitoring systems and other industrial automation systems can be challenging.

- Skilled Workforce: The availability of skilled technicians to install, maintain, and troubleshoot conveyor monitoring systems can be a limiting factor.

Conveyor Monitoring Market: Segmentation Insights

The global conveyor monitoring market is divided by product, application, and region.

Segmentation Insights by Product

Based on Product, the global conveyor monitoring market is divided into heavy conveyor monitoring, light conveyor monitoring, and others.

The Heavy Conveyor Monitoring segment is the dominant segment within the conveyor monitoring market. This dominance is due to the large-scale use of heavy conveyors in industries that require high throughput and continuous operations, such as mining, automotive manufacturing, and steel production. Heavy conveyor monitoring focuses on the monitoring and maintenance of high-capacity and heavy-duty conveyor systems, typically used in industries such as mining, cement production, logistics, and manufacturing. These systems are designed to transport bulk materials, including raw materials, heavy components, and large quantities of products.

Light conveyor monitoring pertains to conveyors used in less demanding applications, such as in food processing, retail, packaging, and assembly lines. These systems are generally smaller in size and capacity compared to heavy conveyors but still require monitoring for optimal operation and safety. As industries become more focused on operational efficiency and reducing operational costs, the need for light conveyor monitoring has increased.

Segmentation Insights by Application

On the basis of Application, the global conveyor monitoring market is bifurcated into mining industry, power generation, oil and gas, and others.

The Mining Industry is the dominant segment in the conveyor monitoring market due to the heavy reliance on conveyor systems for transporting bulk materials in mining operations. Mining is a key industry where conveyor performance directly impacts productivity and operational efficiency. The demand for conveyor monitoring in mining is driven by the need for high-capacity systems to handle heavy materials in rugged and remote environments.

Power generation plants rely heavily on conveyor systems, and any disruption in their operation can lead to significant losses. Monitoring solutions enable plant operators to detect issues early, ensuring smooth operations, improved safety, and reduced maintenance costs. Conveyor systems in power plants are responsible for moving bulk materials, such as coal, ash, or biomass, to and from processing units.

The oil and gas industry faces a constant need to maintain the flow of materials while reducing operational disruptions. Conveyor monitoring systems help operators detect and address issues in real time, especially in harsh and demanding environments. Conveyor systems in the oil and gas industry are used to transport materials like equipment, raw materials, and finished products.

Conveyor Monitoring Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Conveyor Monitoring Market |

| Market Size in 2023 | USD 247.52 Million |

| USD 352.3 Million | |

| Growth Rate | CAGR of 4% |

| Number of Pages | 226 |

| Key Companies Covered | Fenner Dunlop, PHOENIX CBS GMBH, ContiTech Conveyor Belt Group, SKF, Bruel and Kjaer, Beltscan Systems Pty, Yellowtec, Honeywell International, Emerson Electric, Parker Hannifin, and others. |

| Segments Covered | By Product, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Conveyor Monitoring Market: Regional Insights

- North America currently leads the global conveyor monitoring market

North America holds a significant share of the conveyor monitoring market, driven by the high level of automation adoption in industries such as automotive, food and beverage, and logistics. The presence of leading manufacturers, advanced technological infrastructure, and an increasing focus on predictive maintenance are key factors driving growth in this region. The U.S. and Canada are major markets, with widespread use of conveyor systems in both manufacturing and distribution centers.

Europe is a key market for conveyor monitoring systems, with increasing demand from sectors such as manufacturing, mining, and logistics. Countries like Germany, the UK, and France are major contributors to market growth, driven by a strong focus on industrial automation, safety standards, and predictive maintenance.

The region's advanced manufacturing industries, including automotive and food processing, are early adopters of conveyor monitoring technologies. European regulations on safety and operational efficiency further support the adoption of these systems.

The Asia-Pacific region is experiencing the highest growth in the conveyor monitoring market, driven by the rapid industrialization of countries like China, India, and Japan. The increasing adoption of automation in manufacturing and logistics, coupled with the growing demand for efficient and safe conveyor systems, is fueling market growth.

The region's large manufacturing base and expansion in industries such as e-commerce, food processing, and mining are contributing to the increased need for conveyor monitoring solutions.

Latin America is witnessing steady growth in the conveyor monitoring market, with Brazil and Mexico being key markets. The manufacturing sector in the region, particularly in automotive and food processing, is driving the demand for conveyor systems. Additionally, the growing focus on reducing operational costs and improving safety in industries such as mining and logistics is contributing to the market's growth.

The Middle East and Africa region is experiencing gradual growth in the conveyor monitoring market, with increasing investments in industrial automation and safety measures. Countries like the UAE, Saudi Arabia, and South Africa are seeing rising demand for conveyor monitoring systems, especially in sectors such as mining, oil and gas, and logistics. The adoption of smart factory technologies and the need for reliable conveyor systems in harsh operating environments are supporting market growth in this region.

Conveyor Monitoring Market: Competitive Landscape

The report provides an in-depth analysis of companies operating in the conveyor monitoring market, including their geographic presence, business strategies, product offerings, market share, and recent developments. This analysis helps to understand market competition.

Some of the major players in the global conveyor monitoring market include:

- Fenner Dunlop

- PHOENIX CBS GMBH

- ContiTech Conveyor Belt Group

- SKF

- Bruel and Kjaer

- Beltscan Systems Pty

- Yellowtec

- Honeywell International

- Emerson Electric

- Parker Hannifin

The global conveyor monitoring market is segmented as follows:

By Product

- Heavy Conveyor Monitoring

- Light Conveyor Monitoring

By Application

- Mining Industry

- Power Generation

- Oil and Gas

- Others

By Region

- North America

- U.S.

- Canada

- Europe

- U.K.

- France

- Germany

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia Pacific

- Latin America

- Brazil

- Rest of Latin America

- The Middle East and Africa

- GCC Countries

- South Africa

- Rest of Middle East Africa

Frequently Asked Questions

Based on statistics from the Market Research Store, the global conveyor monitoring market size was projected at approximately US$ 247.52 million in 2023. Projections indicate that the market is expected to reach around US$ 352.3 million in revenue by 2032.

The global conveyor monitoring market is expected to grow at a Compound Annual Growth Rate (CAGR) of around 4% during the forecast period from 2024 to 2032.

North America is expected to dominate the global conveyor monitoring market.

Industries are increasingly adopting automation to enhance operational efficiency and reduce downtime are key factors of conveyor monitoring market growth.

Some of the prominent players operating in the global conveyor monitoring market are; Fenner Dunlop, PHOENIX CBS GMBH, ContiTech Conveyor Belt Group, SKF, Bruel and Kjaer, Beltscan Systems Pty, Yellowtec, Honeywell International, Emerson Electric, Parker Hannifin, and others.

Table Of Content

Inquiry For Buying

Conveyor Monitoring

Request Sample

Conveyor Monitoring