Cured Formed-In-Place Gaskets Market Size, Share, and Trends Analysis Report

CAGR :

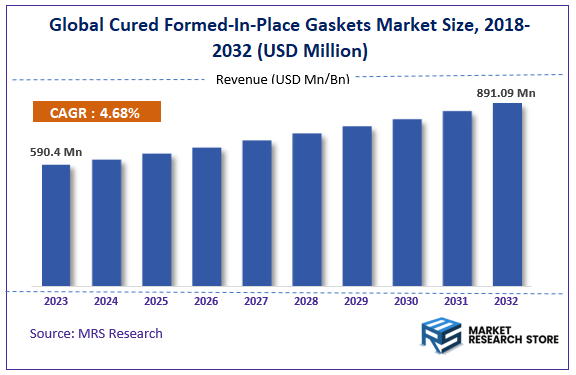

| Market Size 2023 (Base Year) | USD 590.4 Million |

| Market Size 2032 (Forecast Year) | USD 891.09 Million |

| CAGR | 4.68% |

| Forecast Period | 2024 - 2032 |

| Historical Period | 2018 - 2023 |

According to Market Research Store, the global cured formed-in-place gaskets market size was valued at around USD 590.4 million in 2023 and is estimated to reach USD 891.09 million by 2032, to register a CAGR of approximately 4.68% in terms of revenue during the forecast period 2024-2032.

To Get more Insights, Request a Free Sample

The cured formed-in-place gaskets report provides a comprehensive analysis of the market, including its size, share, growth trends, revenue details, and other crucial information regarding the target market. It also covers the drivers, restraints, opportunities, and challenges till 2032.

Global Cured Formed-In-Place Gaskets Market: Overview

Cured formed-in-place gaskets (FIPG) are a type of sealing solution that is applied in a liquid or paste form and then cured to form a solid gasket. These gaskets are typically used in applications where traditional pre-formed gaskets would be difficult to install or where a custom fit is required.

The liquid gasket material is dispensed directly onto the sealing surface, where it cures into a resilient, durable seal. FIPG offers advantages such as reduced material waste, the ability to conform to complex shapes, and enhanced sealing performance by eliminating gaps and inconsistencies found in pre-formed gaskets.

Key Highlights

- The cured formed-in-place gaskets market is anticipated to grow at a CAGR of 4.68% during the forecast period.

- The global cured formed-in-place gaskets market was estimated to be worth approximately USD 590.4 million in 2023 and is projected to reach a value of USD 891.09 million by 2032.

- The growth of the cured formed-in-place gaskets market is being driven by increasing demand for more efficient, reliable, and customizable sealing solutions in industries such as automotive, aerospace, electronics, and industrial equipment.

- Based on the type, the UV-curable form-in-place gaskets segment is growing at a high rate and is projected to dominate the market.

- On the basis of application, the electronic equipment segment is projected to swipe the largest market share.

- By region, North America is expected to dominate the global market during the forecast period.

Cured Formed-In-Place Gaskets Market: Dynamics

Key Growth Drivers:

- Increasing Demand for Automated Manufacturing: The rising adoption of automated manufacturing processes across various industries drives the demand for precise and efficient sealing solutions. Cured formed-in-place gaskets (CIPG) offer a reliable and automated way to achieve this.

- Growth in Automotive and Electronics Industries: The automotive and electronics sectors are major consumers of CIPG due to the stringent requirements for sealing and protection of components.

- Advancements in Gasket Materials: The development of advanced gasket materials with improved properties like temperature resistance, chemical resistance, and electrical insulation enhances the performance and application range of CIPG.

Restraints:

- High Initial Investment Costs: The initial investment in automated dispensing equipment and specialized materials can be significant, which may deter some businesses from adopting CIPG technology.

- Complex Application Processes: The precise application of CIPG requires specialized knowledge and skills, which can increase labor costs and training requirements.

Opportunities:

- Expansion into Emerging Markets: Emerging markets, such as India and China, offer significant growth potential for CIPG due to rapid industrialization and increasing demand for advanced sealing solutions.

- Development of Eco-Friendly CIPG: The development of environmentally friendly CIPG materials with reduced environmental impact can open up new markets and improve brand reputation.

- Integration with IoT and Industry 4.0: Integrating CIPG with IoT and Industry 4.0 technologies can enable real-time monitoring and predictive maintenance, optimizing production processes and reducing downtime.

Challenges:

- Ensuring Consistent Quality and Reliability: Maintaining consistent quality and reliability in CIPG production can be challenging, especially in high-volume manufacturing environments.

- Adherence to Strict Regulatory Standards: The automotive and medical industries have stringent regulatory standards for materials and manufacturing processes, which can increase the complexity and cost of CIPG production.

Cured Formed-In-Place Gaskets Market: Segmentation Insights

The global cured formed-in-place gaskets market is divided by type, application, and region.

Segmentation Insights by Type

Based on type, the global cured formed-in-place gaskets market is divided into UV-curable form in place gaskets and visible light-curable form in place gaskets.

UV-curable form-in-place gaskets are the most dominating segment in the market. These gaskets are created by applying a liquid gasket material that hardens when exposed to ultraviolet (UV) light. The UV-curable technology offers quick curing times, high precision, and excellent adhesion to various substrates. The process allows for accurate application, which is crucial in industries such as automotive, electronics, and manufacturing, where tight seals are required to prevent leaks.

These gaskets are preferred in environments where speed, efficiency, and environmental resistance (e.g., high temperatures, chemical exposure) are key factors. Their popularity stems from their ability to be used in automated systems and for high-volume production due to their fast-curing capabilities.

Visible light-curable form-in-place gaskets are a growing segment, though not as dominant as the UV-curable variety. These gaskets are similar to UV-curable ones, but they require visible light, typically in the blue or violet spectrum, to cure the gasket material.

They are particularly advantageous in scenarios where UV light may not be practical or when there are specific safety or equipment constraints with UV curing. Visible light-curable gaskets offer environmental benefits as they can be safer for workers and the surrounding environment. They are often used in industries where UV curing could interfere with the integrity of sensitive components, like certain electronic parts. While not as fast as UV-curable gaskets, the visible light-curable option is still valued for its ease of use and suitability for particular applications.

Segmentation Insights by Application

On the basis of application, the global cured formed-in-place gaskets market is bifurcated into electronic equipment, fuel cell assembly, sealed underwater housing, heat sealing, speaker assembly and noise reduction, and other.

The electronic equipment segment is one of the most significant applications for cured formed-in-place gaskets. These gaskets are used to create seals for sensitive electronic devices, preventing moisture, dust, and contaminants from entering the equipment. Common applications include smartphones, laptops, televisions, and other consumer electronics. In electronics, gaskets are vital for maintaining the integrity of circuits and components by providing effective insulation and protection.

The flexibility and precision of FIPG technology are highly beneficial for ensuring tight seals around complex components in compact spaces. This segment is driven by the ongoing growth of the electronics industry and the increasing demand for devices with better performance and durability.

Fuel cell assembly is another key application for cured formed-in-place gaskets, especially with the rise in demand for cleaner energy solutions. These gaskets play a crucial role in sealing fuel cells, preventing leaks of gases such as hydrogen and oxygen, which are vital for the fuel cell’s operation.

The use of FIPG in fuel cell assembly ensures that the fuel cells perform efficiently under varying environmental conditions by providing airtight seals. Fuel cell technology, particularly in the automotive and renewable energy sectors, has seen significant growth, thus expanding the market for FIPG gaskets in this area.

Sealed underwater housing is an essential application for cured formed-in-place gaskets, particularly in industries like marine exploration, underwater photography, and diving equipment. These gaskets are used to provide watertight seals for electronic devices and cameras that are housed in underwater enclosures.

The gaskets ensure that no water enters these enclosures, protecting sensitive electronics from water damage. The demand for waterproof technologies in consumer and professional underwater equipment is driving the use of FIPG gaskets in this application.

In heat sealing applications, cured formed-in-place gaskets are used to provide reliable, heat-resistant seals for packaging and industrial processes. These gaskets are often employed in the food and beverage industry, where they help ensure that packaging is airtight and tamper-proof.

FIPG gaskets can withstand high temperatures, making them ideal for heat sealing processes, where the sealing material must endure exposure to elevated temperatures without losing its sealing capability. The versatility and thermal resistance of these gaskets make them a popular choice in heat sealing machinery.

The speaker assembly and noise reduction application is growing rapidly as the demand for high-quality audio devices increases. FIPG gaskets are used in the assembly of speakers to create airtight seals between different parts of the speaker, which helps enhance sound quality by preventing sound leakage.

These gaskets also contribute to noise reduction by ensuring that the speaker’s components remain properly sealed and insulated from external vibrations or noise. As the audio industry continues to advance with new technologies and premium sound systems, the demand for high-performance FIPG gaskets in speaker assemblies is also expected to rise.

Cured Formed-In-Place Gaskets Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Cured Formed-In-Place Gaskets Market |

| Market Size in 2023 | USD 590.4 Million |

| USD 891.09 Million | |

| Growth Rate | CAGR of 4.68% |

| Number of Pages | 216 |

| Key Companies Covered | Henkel, Dymax Corporation, 3M, Dow, Wacker Chemie, ThreeBond Group, DELO, Master Bond, and others. |

| Segments Covered | By Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Cured Formed-In-Place Gaskets Market: Regional Insights

- North America is expected to dominates the global market

North America is the leading region in the cured formed-in-place gaskets market, driven by the significant presence of automotive, aerospace, and electronics industries. The region benefits from advanced manufacturing technologies and strong demand for high-quality sealing solutions. The U.S., in particular, remains the dominant market within North America, owing to its robust industrial base and a growing trend toward lightweight and energy-efficient materials. Mexico is also becoming an important manufacturing hub, with increasing demand for gaskets in automotive and electronic applications.

Europe ranks second, with key markets such as Germany, France, and the UK. The region's market growth is primarily fueled by the automotive, energy, and industrial machinery sectors. Germany's strong automotive industry and its push for electric vehicle manufacturing significantly contribute to the demand for advanced sealing solutions. Regulatory standards in Europe favor high-quality and eco-friendly materials, which supports the demand for cured formed-in-place gaskets.

Asia-Pacific (APAC) is experiencing rapid growth, especially in countries like China, India, and Japan. The region benefits from an expanding manufacturing sector, especially in automotive, electronics, and consumer goods industries. China's large-scale industrial production and Japan's technological advancements in gasket production are key drivers. India’s rising automotive production and increasing industrialization also play a significant role in the market's expansion. Additionally, the growing demand for consumer electronics in countries like South Korea and Taiwan adds further momentum.

South America has a relatively smaller share of the market but is growing steadily. Brazil is the primary market, with demand driven by automotive and industrial applications. As the region continues to industrialize, the need for sealing solutions in machinery and manufacturing processes is increasing. However, South America faces challenges such as economic volatility and infrastructure constraints, which may impact growth potential in the short term.

Middle East and Africa (MEA) is the least dominant region but shows potential due to increasing infrastructure projects, especially in countries like Saudi Arabia and the UAE. The region's demand for cured formed-in-place gaskets is driven by its growing industrial base in the automotive and oil & gas sectors. However, limited manufacturing capacity and reliance on imports restrict the market's growth compared to other regions.

Cured Formed-In-Place Gaskets Market: Competitive Landscape

The report provides an in-depth analysis of companies operating in the cured formed-in-place gaskets market, including their geographic presence, business strategies, product offerings, market share, and recent developments. This analysis helps to understand market competition.

Some of the major players in the global cured formed-in-place gaskets market include:

- Henkel

- Dymax Corporation

- 3M

- Dow

- Wacker Chemie

- ThreeBond Group

- DELO

- Master Bond

The global cured formed-in-place gaskets market is segmented as follows:

By Type

- UV-Curable Form in Place Gaskets

- Visible Light-Curable Form in Place Gaskets

By Application

- Electronic Equipment

- Fuel Cell Assembly

- Sealed Underwater Housing

- Heat Sealing

- Speaker Assembly and Noise Reduction

- Other

By Region

- North America

- U.S.

- Canada

- Europe

- U.K.

- France

- Germany

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia Pacific

- Latin America

- Brazil

- Rest of Latin America

- The Middle East and Africa

- GCC Countries

- South Africa

- Rest of Middle East Africa

Frequently Asked Questions

Based on statistics from the Market Research Store, the global cured formed-in-place gaskets market size was projected at approximately US$ 590.4 million in 2023. Projections indicate that the market is expected to reach around US$ 891.09 million in revenue by 2032.

The global cured formed-in-place gaskets market is expected to grow at a Compound Annual Growth Rate (CAGR) of around 4.68% during the forecast period from 2024 to 2032.

North America is expected to dominate the global cured formed-in-place gaskets market.

The global cured formed-in-place gaskets market is driven by increasing demand for customizable, efficient sealing solutions, particularly in the automotive and aerospace industries. Factors such as advancements in materials, improved curing technologies, and the need for lightweight, reliable seals in complex applications are also contributing to market growth.

Some of the prominent players operating in the global cured formed-in-place gaskets market are; Henkel, Dymax Corporation, 3M, Dow, Wacker Chemie, ThreeBond Group, DELO, Master Bond, and others.

Table Of Content

Inquiry For Buying

Cured Formed-In-Place Gaskets

Request Sample

Cured Formed-In-Place Gaskets