Hard Rock Tunnel Boring Machine Market Size, Share, and Trends Analysis Report

CAGR :

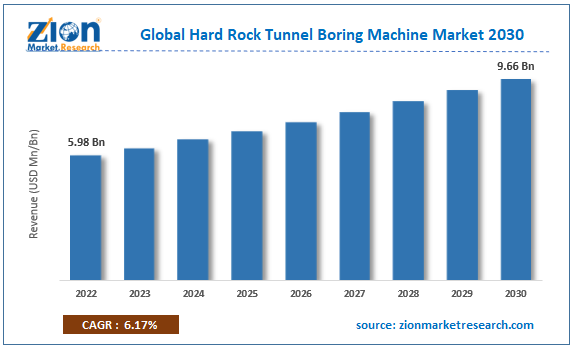

| Market Size 2023 (Base Year) | USD 5.98 Billion |

| Market Size 2032 (Forecast Year) | USD 9.66 Billion |

| CAGR | 6.17% |

| Forecast Period | 2024 - 2032 |

| Historical Period | 2018 - 2023 |

Hard Rock Tunnel Boring Machine Industry Prospective:

The global hard rock tunnel boring machine market size was worth around USD 5.98 billion in 2023 and is predicted to grow to around USD 9.66 billion by 2032 with a compound annual growth rate (CAGR) of roughly 6.17% between 2024 and 2032.

To Get more Insights, Request a Free Sample

Hard Rock Tunnel Boring Machine Market: Overview

A hard rock tunnel boring machine is used for the excavation of tunnels through hard rock. While tunnels can be excavated through sand, wet, or dry soil, these machines are used specifically for tunneling through a segment of large rock. Typically, the cross-section of a hard rock tunnel boring machine is circular but can be customized in other shapes including square, u-shape, rectangular, and horseshoe. These machines are considered alternatives to other methods of tunnel excavation such as drilling & blasting (D&B) or hard mining. The main advantage of using hard rock tunnel machines is that they exhibit limited disturbance in areas surrounding the tunnel and help in creating a smooth tunnel wall. For tunneling through urban areas, hard rock tunneling machines are preferred over other methods of tunnel excavation; however, they are not recommended for tunnels made of sheared or fractured rock. The machines are made of 4 main components. The first is the rotating cutting wheel at the front followed by the main bearing system, thrust systems, and ancillary parts. The cutting wheel is called the cutting head. The main types of hard rock tunnel boring machines include open beam, shielded, slurry shield, earth pressure balance machine, micro-tunnel shield, and open face soft ground.

Key Insights:

- As per the analysis shared by our research analyst, the global hard rock tunnel boring machine market is estimated to grow annually at a CAGR of around 6.17% over the forecast period (2023-2030)

- In terms of revenue, the global hard rock tunnel boring machine market size was valued at around USD 5.98 billion in 2022 and is projected to reach USD 9.66 billion, by 2030.

- The hard rock tunnel boring machine market is projected to grow at a significant rate due to the increasing underground rail construction

- Based on application segmentation, railway & highway was predicted to show maximum market share in the year 2022

- Based on type segmentation, both positive and negative slope segments grew at a steady pace in 2022

- On the basis of region, North America was the leading revenue generator in 2022

Hard Rock Tunnel Boring Machine Market: Growth Drivers

Increasing underground rail construction to drive market growth

The global hard rock tunnel boring machine market is expected to grow owing to the increasing underground rail construction projects as infrastructure development projects are on the rise. One of the primary reasons for the rising focus on underground development is to reduce the pressure on roads due to rising traffic levels. Factors such as urbanization, increasing sales of passenger vehicles, less demand for public transport facilities on roads, and rising population have caused global traffic levels to reach unprecedented levels. The effects of rising traffic jams are multifold since they are also associated with increased fuel consumption and higher environmental pollution such as noise and air pollution. Furthermore, underground railway systems are an excellent way of creating a connection between urban and remote areas. In September 2023, India witnessed the official commencement of a massive underground railway project in Mumbai city. The 54-month-long project will deal with the construction of the BKC station connecting Mumbai-Ahmedabad through bullet trains. The underground tunnel for the project is 32 meters deep.

Increasing developments in machine features to push market revenue

The hard rock tunnel boring machine industry will benefit from the increasing innovation-oriented undertakings by machine designers and manufacturers. In December 2019, Robbins, a leading pioneer in the underground construction machinery industry, launched the largest hard rock TBM in the US at Mill Creek. The Main Beam TBM has a diameter of 11.6 m and will be used for the excavation of the 8 km Mill Creek Drainage Relief tunnel. One of the key features of the machine is its adaptability since the unique design of the Main Beam TBM is expected to change size partway while boring to a smaller size of approximately 9.9 m

Hard Rock Tunnel Boring Machine Market: Restraints

High construction cost of TBMs to restrict the market growth

Hard rock TBMs are complex machinery. They are made of heavy metals and use sophisticated designs for functioning. The construction of these machines is highly resource-intensive including manpower, energy, and associated technology. Furthermore, transporting larger machines is difficult due to their heavy structure. The construction of a small hard rock TBM can reach as high as USD 5 million while larger machines are known to cost over USD 30 million. These factors restrict the number of players in the market thus limiting its growth rate.

Hard Rock Tunnel Boring Machine Market: Opportunities

Rising mining activities globally to create expansion possibilities

The global hard rock tunnel boring machine market demand for hard rock TBMs is projected to continue witnessing new growth possibilities due to the rising mining activities across the globe. Surging demand for types of mining products including coal, gold, limestone, metals, rock salt, and other products influenced by industrialization, globalization, and consumerism has led to an increase in overall mining activities. As per official reports, the world’s top 40 mining companies earned a total revenue of USD 945 billion in 2022. Hard rock TBMs are standard machines used during mining procedures due to their ability to tunnel through extremely difficult terrain. For instance, in September 2021, the world’s leading producer of TBMs Robbin and Fresnillo, mine owner of Mexico’s oldest silver mining unit collaborated with machinery firm Topo to develop a novel machine that could bore through hard rock and resolve the unit’s mining challenge. The MDM5000 – mine development machine was made with a rectangular profile to bore through andesite and shale with quartz intrusions that resulted in previous failed mining attempts.

Hard Rock Tunnel Boring Machine Market: Challenges

Requirement of skilled labor to construct and operate the machines are existing challenge

One of the key challenges faced by hard rock TBMs is the extensive reliance on skilled labor for the construction of these mammoth machinery. Additionally, they can only be operated in the presence of experts who understand machine functionalities and features. However, there is a significant gap in the demand and availability of technical experts causing challenges for hard rock tunnel boring machine industry players planning on business expansion. Moreover, the changing prices and supply of raw materials, the volatile international trade ecosystem, and managing machine technical failures on-site add to the current challenges.

Hard Rock Tunnel Boring Machine Market: Segmentation

The global hard rock tunnel boring machine market is segmented based on application, type, and region.

Based on application, the global market segments are municipal engineering, railway & highway, underground storage facilities, power & energy, and others. In 2022, the highest growth was observed in the railway & highway segment owing to the increasing infrastructure development projects especially targeting public transport systems and creating large-interconnected road networks for facilitating improved regional transport systems. The Australian government will be spending $A 50-100bn on Melbourne's 90 km suburban loop in Victoria. The loop will consist of a 25 km underground stretch. The power & energy segment is expected to grow at a steady pace

Based on type, the hard rock tunnel boring machine industry is divided into positive slope and negative slope. Both variants enjoy a considerable share of total revenue since the choice of slope depends on the exact structure of the hard rock segment being bored. For instance, positive slope hard rock TBM is used when the tunnel advancement segment is inclined in an upward direction while negative slope is used for downward-directed tunnel advancement. The latter has higher applications in the construction of drainage systems. The low tunneling rate of TBMs which can range between 15 km/year and 15 m/year is one of the crucial drawbacks of hard rock tunnel boring machines.

Hard Rock Tunnel Boring Machine Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Hard Rock Tunnel Boring Machine Market |

| Market Size in 2023 | USD 5.98 Billion |

| Market Forecast in 2032 | USD 9.66 Billion |

| Growth Rate | CAGR of 6.17% |

| Number of Pages | 140 |

| Key Companies Covered | Caterpillar Inc. (formerly Lovat), Herrenknecht AG, NHI Group, TBM Service Group, The Robbins Company, Kawasaki Heavy Industries Ltd., CRCHI, MITSUBISHI ROCK TOOLS, Komatsu Ltd., Northern Tunneling Equipment (NTE), Hitachi Zosen Corporation, SELI Overseas S.p.A., Akkerman Inc., and others. |

| Segments Covered | By Application, By Type, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Hard Rock Tunnel Boring Machine Market: Regional Analysis

Growth in North America to be driven by growing investments in drainage systems

The global hard rock tunnel boring machine market is expected to witness the highest growth in North America with the US leading as the dominant regional shareholder. The primary reason for North America’s undefeated growth rate is the large-scale focus on managing drainage systems in urban and remote areas. A July 2023 official report emphasized the importance of improving current drainage networks in the US since they are unable to hold the intense rain pressure caused by changes in climate conditions. Furthermore, riding focus on controlled water conveyance and sanitation networks could drive regional market trends. The US is home to one of the largest manufacturers of hard TBMs in the form of the Robbins Company. It supplies machines to all major infrastructure and mining projects. In 2019, the Double Shield TBM by Robbins helped bore the longest rock tunnel at the Parmer Lane Wastewater Interceptor in Austin. Other factors such as increasing work on customized solutions, and growing international sales of US-made hard rock TBMs could further push regional revenue.

Hard Rock Tunnel Boring Machine Market: Competitive Analysis

The global hard rock tunnel boring machine market is led by players like:

- Caterpillar Inc. (formerly Lovat)

- Herrenknecht AG

- NHI Group

- TBM Service Group

- The Robbins Company

- Kawasaki Heavy Industries Ltd.

- CRCHI

- MITSUBISHI ROCK TOOLS

- Komatsu Ltd.

- Northern Tunneling Equipment (NTE)

- Hitachi Zosen Corporation

- SELI Overseas S.p.A.

- Akkerman Inc.

The global hard rock tunnel boring machine market is segmented as follows:

By Application

- Municipal Engineering

- Railway & Highway

- Underground Storage Facilities

- Power & Energy

- Others

By Type

- Positive Slope

- Negative Slope

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Frequently Asked Questions

A hard rock tunnel boring machine is used for the excavation of tunnels through hard rock.

The hard rock tunnel boring machine market is projected to grow at a significant rate due to the increasing underground rail construction.

According to study, the global hard rock tunnel boring machine market size was worth around USD 5.98 billion in 2023 and is predicted to grow to around USD 9.66 billion by 2032.

The CAGR value of the hard rock tunnel boring machine market is expected to be around 6.17% during 2024-2032.

The global hard rock tunnel boring machine market is expected to witness the highest growth in North America with the US leading as the dominant regional shareholder.

The global hard rock tunnel boring machine market is led by players like Caterpillar Inc. (formerly Lovat), Herrenknecht AG, NHI Group, TBM Service Group, The Robbins Company, Kawasaki Heavy Industries, Ltd., CRCHI, MITSUBISHI ROCK TOOLS, Komatsu Ltd., Northern Tunneling Equipment (NTE), Hitachi Zosen Corporation, SELI Overseas S.p.A., and Akkerman Inc.

The report explores crucial aspects of the hard rock tunnel boring machine market including a detailed discussion of existing growth factors and restraints while also browsing future growth opportunities and challenges that impact the market.

Table Of Content

Inquiry For Buying

Hard Rock Tunnel Boring Machine

Request Sample

Hard Rock Tunnel Boring Machine