Inorganic Ceramic Binders Market Size, Share, and Trends Analysis Report

CAGR :

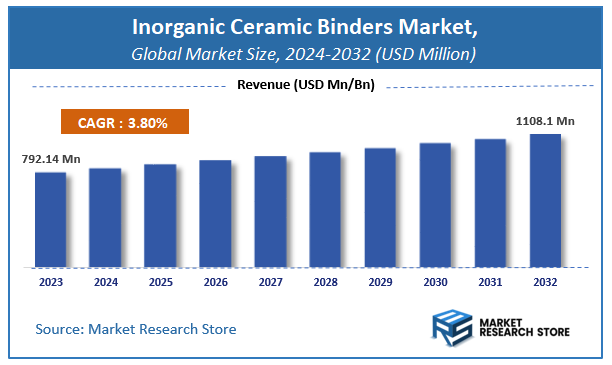

| Market Size 2023 (Base Year) | USD 792.14 Million |

| Market Size 2032 (Forecast Year) | USD 1108.1 Million |

| CAGR | 3.8% |

| Forecast Period | 2024 - 2032 |

| Historical Period | 2018 - 2023 |

Inorganic Ceramic Binders Market Insights

According to Market Research Store, the global inorganic ceramic binders market size was valued at around USD 792.14 million in 2023 and is estimated to reach USD 1108.1 million by 2032, to register a CAGR of approximately 3.8% in terms of revenue during the forecast period 2024-2032.

The inorganic ceramic binders report provides a comprehensive analysis of the market, including its size, share, growth trends, revenue details, and other crucial information regarding the target market. It also covers the drivers, restraints, opportunities, and challenges till 2032.

To Get more Insights, Request a Free Sample

Global Inorganic Ceramic Binders Market: Overview

The Inorganic Ceramic Binders Market involves the production and application of inorganic binders used in the manufacturing of ceramics, including those in the aerospace, automotive, construction, and energy industries. These binders are essential in the fabrication of ceramic products, providing strength, stability, and durability during the sintering process. Inorganic ceramic binders are typically made from materials such as silica, alumina, or zirconia, which offer high-temperature resistance, chemical stability, and mechanical strength, essential properties for advanced ceramics used in high-performance applications.

The market is driven by the increasing demand for advanced ceramics in applications such as catalytic converters, cutting tools, electronics, and refractories, where inorganic ceramic binders play a critical role in improving the overall performance of the final products. The growth of industries like automotive, aerospace, energy, and electronics is boosting the demand for high-performance ceramic products that require robust and reliable binders.

Key Highlights

- The inorganic ceramic binders market is anticipated to grow at a CAGR of 3.8% during the forecast period.

- The global inorganic ceramic binders market was estimated to be worth approximately USD 792.14 million in 2023 and is projected to reach a value of USD 1108.1 million by 2032.

- The growth of the inorganic ceramic binders market is being driven by the increasing demand for high-performance ceramics across various industries, coupled with the growing focus on sustainability and environmental concerns.

- Based on the product, the alumina segment is growing at a high rate and is projected to dominate the market.

- On the basis of application, the advanced ceramics segment is projected to swipe the largest market share.

- By region, North America is expected to dominate the global market during the forecast period.

Inorganic Ceramic Binders Market: Dynamics

Key Drivers

- Construction Boom: The growing global construction industry, driven by urbanization and infrastructure development, fuels the demand for ceramics in building materials like tiles, bricks, and refractories.

- Advancements in Ceramics Manufacturing: Advancements in ceramic processing techniques, such as 3D printing and advanced sintering methods, are driving the need for innovative binder systems.

- Demand for High-Performance Ceramics: Increasing demand for high-performance ceramics in various applications, including aerospace, automotive, and electronics, necessitates the use of specialized binders.

- Sustainability Concerns: Growing emphasis on sustainability is driving the demand for environmentally friendly binders with low environmental impact.

Restraints

- High Material Costs: Some inorganic binders can be relatively expensive, which can increase production costs.

- Environmental Concerns: Concerns about the environmental impact of certain binder materials and their production processes.

- Competition from Organic Binders: Competition from organic binders, which offer certain advantages in terms of processability and cost.

- Regulatory Compliance: Adherence to strict environmental and safety regulations related to the use of certain binder materials.

Opportunities

- Development of Novel Binders: Development of novel inorganic binders with improved properties, such as enhanced green strength, reduced shrinkage, and improved environmental compatibility.

- Nano-engineered Binders: Development of nano-engineered binders with tailored properties for specific applications.

- Recycling and Reuse: Exploring opportunities for recycling and reusing binder materials to reduce waste and minimize environmental impact.

- Expanding into New Applications: Exploring new applications for inorganic ceramic binders in emerging fields, such as 3D printing, bioceramics, and energy storage.

Challenges

- Maintaining Product Quality and Consistency: Ensuring consistent quality and performance of binder materials across different production batches.

- Meeting Environmental Regulations: Adhering to evolving environmental regulations and minimizing the environmental impact of binder production and use.

- Staying Competitive: Staying competitive in a dynamic market with continuous advancements in materials science and manufacturing technologies.

- Addressing Supply Chain Disruptions: Mitigating the impact of potential supply chain disruptions on the availability and pricing of raw materials.

Inorganic Ceramic Binders Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Inorganic Ceramic Binders Market |

| Market Size in 2023 | USD 792.14 Million |

| Market Forecast in 2032 | USD 1108.1 Million |

| Growth Rate | CAGR of 3.8% |

| Number of Pages | 140 |

| Key Companies Covered | 3M Company, BASF SE, Dow Inc., Henkel AG & Co. KGaA, Saint-Gobain S.A., Kao Corporation, Nippon Sheet Glass Co., Ltd., Vesuvius plc, Morgan Advanced Materials plc, Imerys S.A., Sika AG, Almatis GmbH, Unifrax I LLC, Zircar Ceramics Inc., AGC Inc., Kyocera Corporation, CeramTec GmbH, RHI Magnesita N.V., H.C. Starck GmbH, Advanced Ceramic Materials (ACM) Corporation |

| Segments Covered | By Product Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2023 |

| Forecast Year | 2024 to 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Inorganic Ceramic Binders Market: Segmentation Insights

The global inorganic ceramic binders market is divided by product, application, and region.

Segmentation Insights by Product

Based on Product, the global inorganic ceramic binders market is divided into alumina, silica, metal powder, and other.

Alumina as the dominant product segment in the inorganic ceramic binders market, driven by its superior properties and widespread applications in industrial and high-performance ceramic manufacturing. Alumina binders are extensively used in industries such as automotive, aerospace, and construction for making high-performance ceramic components and refractory products.

Silica-based ceramic binders are popular for their low cost, high availability, and excellent binding properties. The widespread use of silica binders in construction and electronics sectors underpins their strong market position. However, competition from advanced materials could moderate growth.

Metal Powder-based ceramic binders are used to produce metal-matrix composites and advanced ceramics. These binders provide superior mechanical strength, thermal conductivity, and wear resistance. The growing demand for metal powder binders in high-performance engineering applications, particularly in aerospace and defense, is driving this segment’s growth.

Segmentation Insights by Application

On the basis of Application, the global inorganic ceramic binders market is bifurcated into advanced ceramics, traditional ceramics, abrasives, and others.

Advanced Ceramics as the dominant application segment in the inorganic ceramic binders market, supported by their widespread use in high-performance and specialized applications across various industries. The increasing demand for high-performance materials in cutting-edge technologies is a significant driver for this segment. Additionally, the growth of renewable energy and electric vehicles further boosts demand for advanced ceramics.

Traditional Ceramics include products such as tiles, bricks, pottery, and sanitary ware that rely heavily on inorganic ceramic binders for enhanced structural integrity and durability. The demand for traditional ceramics is driven by construction activities, particularly in emerging economies, where urbanization is leading to increased infrastructure development.

Abrasives are materials used for grinding, polishing, or cleaning surfaces, and ceramic binders are essential for their production, providing the required hardness and wear resistance. The growth in manufacturing and construction industries, along with the demand for high-quality surface finishing, is driving the market for ceramic binders in abrasive applications.

Inorganic Ceramic Binders Market: Regional Insights

- North America currently leads the global inorganic ceramic binders market

North America is a significant market for inorganic ceramic binders, driven by advancements in the automotive and aerospace industries. The U.S., in particular, leads due to its established industrial base, substantial R&D investments, and increasing demand for high-performance ceramics in manufacturing processes. The region's focus on sustainable construction and advanced technologies further fuels the adoption of inorganic ceramic binders in various applications, including refractory materials, coatings, and adhesives.

Europe is another key region for the inorganic ceramic binders market, with strong contributions from countries like Germany, the UK, and France. The region's emphasis on green building initiatives and lightweight automotive components has increased the demand for advanced ceramics. Industries such as aerospace and electronics also contribute significantly to the market, as these sectors require high-performance materials for heat resistance and durability. Europe's stringent environmental regulations encourage the use of eco-friendly and non-toxic ceramic binders, fostering market growth.

The Asia-Pacific region is the fastest-growing market for inorganic ceramic binders, driven by rapid industrialization, urbanization, and infrastructure development. Countries such as China, India, Japan, and South Korea are key players, with high demand from the construction, automotive, and electronics industries. The increasing adoption of ceramic materials in advanced manufacturing processes, coupled with government initiatives to boost industrial growth, is propelling the market. Additionally, the region's expanding renewable energy sector, including solar panels and wind turbines, supports the use of ceramic binders in energy applications.

Latin America is an emerging market for inorganic ceramic binders, with Brazil and Mexico at the forefront. The region's growing construction industry and increasing investment in infrastructure projects drive demand for ceramic materials and binders. While the market is still developing, rising awareness of the advantages of ceramic binders in high-temperature and wear-resistant applications is expected to fuel growth. However, economic instability in some countries may act as a restraint.

The Middle East and Africa (MEA) region is gradually adopting inorganic ceramic binders, primarily driven by the construction and oil and gas sectors. Countries like Saudi Arabia, the UAE, and South Africa are key markets in the region. The increasing focus on infrastructure development and the need for durable materials in extreme environments are boosting demand. However, the lack of advanced manufacturing facilities and reliance on imports could limit market expansion in certain parts of the region.

Inorganic Ceramic Binders Market: Competitive Landscape

The report provides an in-depth analysis of companies operating in the inorganic ceramic binders market, including their geographic presence, business strategies, product offerings, market share, and recent developments. This analysis helps to understand market competition.

Some of the major players in the global inorganic ceramic binders market include:

- Almatis

- ECOLAB

- Imerys Group

- Kuraray

- Shreejichemicals

- ZIRCAR Ceramics

The global inorganic ceramic binders market is segmented as follows:

By Product

- Alumina

- Silica

- Metal Powder

- Others

By Application

- Advanced Ceramics

- Traditional Ceramics

- Abrasives

- Others

By Region

- North America

- U.S.

- Canada

- Europe

- U.K.

- France

- Germany

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia Pacific

- Latin America

- Brazil

- Rest of Latin America

- The Middle East and Africa

- GCC Countries

- South Africa

- Rest of Middle East Africa

Frequently Asked Questions

Based on statistics from the Market Research Store, the global inorganic ceramic binders market size was projected at approximately US$ 792.14 million in 2023. Projections indicate that the market is expected to reach around US$ 1108.1 million in revenue by 2032.

The global inorganic ceramic binders market is expected to grow at a Compound Annual Growth Rate (CAGR) of around 3.8% during the forecast period from 2024 to 2032.

North America is expected to dominate the global inorganic ceramic binders market.

The global inorganic ceramic binders market is primarily driven by factors such as increasing demand for advanced ceramics in various industries, including electronics, aerospace, and automotive.

Some of the prominent players operating in the global inorganic ceramic binders market are; Almatis, ECOLAB, Imerys Group, Kuraray, Shreejichemicals, ZIRCAR Ceramics, and others.

Table Of Content

Inquiry For Buying

Inorganic Ceramic Binders

Request Sample

Inorganic Ceramic Binders