Machined Seals Market Size, Share, and Trends Analysis Report

CAGR :

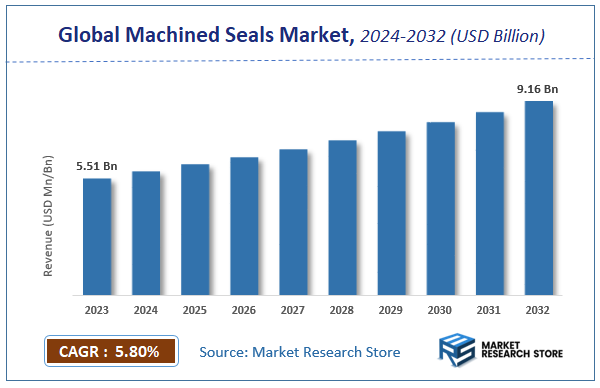

| Market Size 2023 (Base Year) | USD 5.51 Billion |

| Market Size 2032 (Forecast Year) | USD 9.16 Billion |

| CAGR | 5.8% |

| Forecast Period | 2024 - 2032 |

| Historical Period | 2018 - 2023 |

Machined Seals Market Insights

According to Market Research Store, the global machined seals market size was valued at around USD 5.51 billion in 2023 and is estimated to reach USD 9.16 billion by 2032, to register a CAGR of approximately 5.8% in terms of revenue during the forecast period 2024-2032.

The machined seals report provides a comprehensive analysis of the market, including its size, share, growth trends, revenue details, and other crucial information regarding the target market. It also covers the drivers, restraints, opportunities, and challenges till 2032.

To Get more Insights, Request a Free Sample

Global Machined Seals Market: Overview

Machined seals are custom-engineered sealing components that are manufactured through precision machining processes to meet specific application requirements in various industrial systems. Unlike standard molded seals, machined seals are produced from solid polymer or elastomeric materials using CNC (Computer Numerical Control) equipment, allowing for rapid prototyping and on-demand production. These seals are used in hydraulic cylinders, pumps, valves, and rotating equipment to prevent leakage of fluids or gases, maintain pressure, and protect internal components from contamination or wear.

The growth of the machined seals market is driven by the increasing need for highly reliable and application-specific sealing solutions in industries such as oil and gas, aerospace, construction, marine, and automotive. As equipment designs become more complex and operate under extreme conditions—including high pressure, temperature, or chemical exposure—machined seals offer superior customization, quick turnaround times, and enhanced material performance. The trend toward just-in-time manufacturing and reduced downtime has further accelerated demand for on-site or rapidly sourced machined sealing solutions. Advancements in material science, particularly in thermoplastics and high-performance elastomers, continue to expand the range and functionality of machined seals across critical applications.

Key Highlights

- The machined seals market is anticipated to grow at a CAGR of 5.8% during the forecast period.

- The global machined seals market was estimated to be worth approximately USD 5.51 billion in 2023 and is projected to reach a value of USD 9.16 billion by 2032.

- The growth of the machined seals market is being driven by the increasing demand for high-performance sealing solutions across a diverse range of industrial sectors.

- Based on the end-user, the automotive industry segment is growing at a high rate and is projected to dominate the market.

- On the basis of type, the fluid power seals segment is projected to swipe the largest market share.

- By region, North America is expected to dominate the global market during the forecast period.

Machined Seals Market: Dynamics

Key Growth Drivers:

- Growing Industrialization and Infrastructure Development: Rapid industrial expansion and infrastructure projects, particularly in emerging economies (e.g., Asia-Pacific, Latin America), are driving the demand for new machinery and equipment across sectors like manufacturing, construction, power generation, and water treatment, all of which require specialized sealing solutions.

- Increasing Demand from Process Industries: Industries such as oil & gas, chemicals, pharmaceuticals, and food & beverage require robust and reliable seals due to the presence of corrosive fluids, extreme temperatures, and high pressures. Machined seals are crucial for preventing leaks, ensuring safety, and maintaining operational efficiency in these demanding environments.

- Stringent Environmental and Safety Regulations: Governments and regulatory bodies worldwide are imposing stricter environmental and safety standards to prevent leaks of hazardous materials and reduce emissions. This drives the adoption of high-performance machined seals that ensure compliance and minimize environmental impact.

- Technological Advancements in Material Science: Continuous innovation in sealing materials, including high-performance elastomers, thermoplastics (like advanced PTFE and PEEK), and composite materials, enables the development of seals with superior chemical resistance, thermal stability, low friction, and mechanical strength, expanding their application range.

- Focus on Equipment Efficiency and Longevity: Industries are increasingly prioritizing solutions that reduce downtime, lower maintenance costs, and extend the operational life of their machinery. Machined seals contribute significantly to these goals by preventing wear and tear, reducing friction, and ensuring optimal system performance.

- Growing Adoption of Automation and Robotics: The expansion of automation and robotics in manufacturing and other industries necessitates high-precision and durable seals that can withstand continuous movement, high speeds, and repetitive operations while protecting sensitive components from contaminants.

- Demand for Customization and Application-Specific Solutions: As industrial machinery becomes more complex and specialized, there's a rising need for tailor-made sealing solutions that precisely fit unique application requirements, which is a core strength of machined seals over standard seals.

Restraints:

- Fluctuating Raw Material Prices: The prices of specialized raw materials like high-performance polymers, fluoropolymers, and metals used in machined seals can be volatile. These fluctuations can increase production costs, reduce profit margins, and make it difficult for manufacturers to maintain competitive pricing.

- High Production and Design Complexity: The custom nature of machined seals involves intricate design, precision machining, and specialized manufacturing processes. This complexity can lead to higher production costs and longer lead times compared to mass-produced standard seals.

- Competition from Alternative Sealing Technologies: Machined seals face competition from other sealing methods, such as mechanical seals (for rotating equipment), O-rings, gaskets, and even emerging seal-less pump designs. For certain applications, these alternatives might be perceived as more cost-effective or simpler to implement.

- Need for Specialized Expertise and Equipment: The manufacturing of high-quality machined seals requires specialized CNC machinery, advanced tooling, and a skilled workforce with expertise in material science and precision engineering, which can be a barrier for new entrants and a cost factor for existing players.

- Lengthy Qualification and Testing Processes: For critical applications (e.g., aerospace, medical), machined seals undergo rigorous testing and qualification processes to ensure compliance with strict industry standards, which can be time-consuming and add to overall development costs.

Opportunities:

- Integration with Industry 4.0 and Smart Sealing Solutions: Incorporating sensors into seals for real-time monitoring of pressure, temperature, wear, and leakage can enable predictive maintenance, reduce unscheduled downtime, and improve overall system reliability. This integration with IIoT (Industrial Internet of Things) offers significant growth potential.

- Additive Manufacturing (3D Printing) for Prototyping and Niche Production: The use of 3D printing for specialized polymer seals allows for rapid prototyping, complex geometries, and efficient production of small batches or highly customized seals, reducing lead times and waste.

- Development of Self-Healing and Environmentally Friendly Materials: Research into self-healing polymers that can repair micro-damages, and the use of recycled or biodegradable materials, presents opportunities for more sustainable and longer-lasting sealing solutions, appealing to eco-conscious industries.

- Expansion in Niche High-Growth Industries: Beyond traditional heavy industries, there are growing opportunities in sectors like electric vehicles (EVs), medical devices, semiconductors, and renewable energy (e.g., wind turbines, solar panel manufacturing), all of which require high-performance, specialized seals.

- Aftermarket Sales and Replacement Market: The longevity of industrial equipment ensures a consistent demand for replacement seals during maintenance cycles, creating a stable and significant aftermarket revenue stream for manufacturers.

- Enhanced Performance in Extreme Environments: Continued R&D to develop seals capable of performing in even more extreme conditions (e.g., ultra-high pressures, cryogenic temperatures, highly aggressive chemicals) will open up new applications in challenging operational settings.

- Strategic Partnerships and Mergers & Acquisitions: Collaborations or acquisitions between material suppliers, seal manufacturers, and machinery OEMs can lead to integrated solutions, expanded market reach, and technological synergies.

Challenges:

- Managing Customization at Scale: While customization is a driver, the challenge lies in efficiently managing the high degree of customization demanded by customers, ensuring quality control, and maintaining competitive pricing for small, specialized batches.

- Addressing the Skills Gap: The highly technical nature of machined seals requires a specialized workforce with expertise in material science, design, and manufacturing. Attracting and retaining such skilled professionals is a continuous challenge for the industry.

- Ensuring Data Integrity and Cybersecurity for Smart Seals: As seals become "smart" and connected, ensuring the cybersecurity of embedded sensors and the integrity of the data collected is crucial to prevent system vulnerabilities and maintain trust.

- Compliance with Evolving International Standards: Manufacturers must constantly stay abreast of and comply with a multitude of evolving international and regional standards for materials, performance, and safety in various end-use industries.

- Impact of Economic Downturns: The market is tied to the health of various industrial sectors. Economic downturns or slowdowns in manufacturing, construction, or oil & gas can directly impact the demand for machined seals.

- Competition from In-house Manufacturing: Some large industrial players with significant engineering capabilities might choose to produce certain specialized seals in-house rather than relying on external suppliers, posing a challenge to market growth.

Machined Seals Market: Report Scope

This report thoroughly analyzes the Machined Seals Market, exploring its historical trends, current state, and future projections. The market estimates presented result from a robust research methodology, incorporating primary research, secondary sources, and expert opinions. These estimates are influenced by the prevailing market dynamics as well as key economic, social, and political factors. Furthermore, the report considers the impact of regulations, government expenditures, and advancements in research and development on the market. Both positive and negative shifts are evaluated to ensure a comprehensive and accurate market outlook.

| Report Attributes | Report Details |

|---|---|

| Report Name | Machined Seals Market |

| Market Size in 2023 | USD 5.51 Billion |

| Market Forecast in 2032 | USD 9.16 Billion |

| Growth Rate | CAGR of 5.8% |

| Number of Pages | 176 |

| Key Companies Covered | A.W. Chesterton Co., AB SKF, AccroSeal, Apple Rubber Products Inc., CARCO PRECISION RUBBER PRODUCTS S.P.A, CTG Inc., Datwyler Holding Inc., EnPro Industries Inc., FedTech Inc., Flexaseal Engineered Seals and Systems LLC, Freudenberg and Co. KG, IDEX Corp., James Walker Group Ltd., MFPSeals, Michelin Group, Parker Hannifin Corp., Pawling Engineered Products Inc., SHV Holdings N.V., Trelleborg AB, Vanguard Products Corp |

| Segments Covered | By End-user, By Type, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2023 |

| Forecast Year | 2024 to 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Machined Seals Market: Segmentation Insights

The global machined seals market is divided by end-user, type, and region.

Segmentation Insights by End-user

Based on end-user, the global machined seals market is divided into automotive industry, heavy industry, machine tools industry, and others.

Automotive Industry represents one of the most dominant end-user segments in the machined seals market. This sector relies heavily on high-performance sealing solutions to ensure the reliability, efficiency, and safety of a wide range of components, including engines, transmissions, axles, braking systems, and powertrains. As automotive manufacturers increasingly integrate advanced electronics and electrification technologies (such as electric vehicles and hybrid systems), the demand for custom machined seals that can withstand extreme temperatures, pressures, and chemical exposure is rising significantly. The growing emphasis on improving fuel efficiency, reducing emissions, and enhancing the durability of components also supports this segment's growth. Additionally, the increasing vehicle production rates across both emerging and developed economies contribute to the strong demand for machined seals in OEM manufacturing and aftermarket services.

Heavy Industry also plays a substantial role in driving the machined seals market. This includes sectors such as mining, construction, marine, and energy, where equipment operates under highly abrasive, high-pressure, and contaminated environments. Machined seals are vital in hydraulic and pneumatic systems within heavy machinery, preventing leakage, ensuring operational efficiency, and extending machinery life. The trend toward automation in heavy industries and the growing deployment of large-scale capital equipment are pushing the demand for highly reliable, durable, and customized seal solutions. Moreover, the focus on minimizing downtime and maintenance costs in these mission-critical environments makes machined seals an essential investment, further strengthening this segment’s market presence.

Machine Tools Industry is another key end-user segment, driven by the expanding industrial manufacturing and precision engineering sectors. Machined seals are widely used in various machine tool systems such as CNC machines, lathes, and milling equipment, where sealing performance is critical to maintain accuracy and prevent contamination of lubricants or cutting fluids. As industries demand higher precision and longer maintenance cycles, the need for machined seals capable of withstanding wear, vibration, and thermal variation becomes more pronounced. The global growth of smart manufacturing and Industry 4.0 initiatives is also fostering innovation in machine tool design and integration, which in turn drives the adoption of advanced sealing solutions tailored to specific configurations and performance standards.

Segmentation Insights by Type

On the basis of type, the global machined seals market is bifurcated into fluid power seals, power transmission seals, and large diameter seals.

Fluid Power Seals dominate the machined seals market due to their widespread use and critical role in maintaining system integrity across numerous industrial applications. These seals are essential for hydraulic and pneumatic systems where they prevent leakage of fluids or gases and ensure pressure is maintained. They are widely used in applications such as hydraulic cylinders, valves, pumps, and actuators, especially in industries like construction, mining, agriculture, and material handling. The high demand for fluid power seals stems from their ability to handle high-pressure environments, resist chemical degradation, and maintain performance under varying temperatures. Advancements in fluid system design, along with the push for energy efficiency and leak-free operation, continue to drive the growth of this segment.

Power Transmission Seals are used to seal rotating components, such as shafts and gearboxes, where lubrication retention and contamination exclusion are vital. These seals are crucial in automotive drivetrains, industrial gear systems, electric motors, and mechanical power transfer systems. With the increase in machinery complexity and operating speeds, the need for precision-engineered, durable, and high-performance seals has grown. The ongoing shift toward electric vehicles and renewable energy systems has also spurred innovation in this segment, requiring seals that can withstand high torque loads and thermal stresses.

Large Diameter Seals are specialized machined seals used in heavy-duty and large-scale industrial applications such as wind turbines, marine propulsion systems, tunnel boring machines, and offshore oil and gas platforms. These seals are custom-made for large equipment where traditional molded seals are not feasible due to size and performance constraints. The demand for large diameter seals is rising in infrastructure development, energy projects, and heavy machinery sectors, where reliability, resistance to environmental stressors, and long service life are critical. Their market growth is supported by the trend toward larger, more powerful equipment and increasing global investment in energy infrastructure and heavy engineering.

Machined Seals Market: Regional Insights

- North America is expected to dominate the global market

North America dominates the Machined Seals Market owing to its robust industrial infrastructure, presence of key manufacturing sectors, and technological advancements in sealing solutions. The United States and Canada have well-established industries such as oil & gas, automotive, aerospace, and heavy machinery that drive continuous demand for high-performance machined seals. The region also benefits from major manufacturers like Parker Hannifin, Trelleborg Sealing Solutions, and Freudenberg Sealing Technologies operating advanced production facilities. Additionally, North America shows strong investment in predictive maintenance and customized sealing technologies, which further boost the adoption of machined seals in both OEM and MRO applications.

Europe holds a significant share in the machined seals market due to its sophisticated engineering capabilities and strong focus on quality and precision manufacturing. Countries like Germany, the UK, France, and Italy are leaders in automotive, mechanical engineering, and renewable energy sectors—industries that heavily rely on customized sealing components. European regulations emphasizing leakage prevention, environmental compliance, and machine safety also drive demand for precision-engineered seals. Moreover, the expansion of smart manufacturing and Industry 4.0 initiatives across the region encourages the integration of advanced sealing solutions into automated systems.

Asia-Pacific is the fastest-growing region in the machined seals market, driven by rapid industrialization, urbanization, and expansion of end-use industries such as construction, mining, chemicals, and transportation. China, India, Japan, and South Korea are key contributors due to their large-scale manufacturing bases and growing demand for cost-efficient yet durable seal components. The increase in foreign direct investment, particularly in heavy industry and automotive manufacturing, stimulates demand for localized production and tailored sealing solutions. Rising awareness about machine efficiency and downtime reduction is also accelerating the uptake of high-quality machined seals across industrial sectors.

Latin America is witnessing moderate growth in the machined seals market, led by Brazil, Mexico, and Argentina. The region’s demand is primarily driven by oil & gas exploration, mining, and agricultural machinery sectors. Brazil’s expanding offshore drilling industry and Mexico’s automotive production contribute notably to market traction. However, economic volatility and infrastructure limitations in some parts of the region can restrict large-scale adoption. Nevertheless, increasing investments in industrial modernization and equipment maintenance create opportunities for machined seal suppliers offering durable and custom-fit products.

Middle East and Africa are emerging regions for the machined seals market, with demand primarily concentrated in the oil & gas, construction, and water treatment industries. Countries like the UAE and Saudi Arabia are investing heavily in industrial diversification and infrastructure projects under initiatives like Saudi Vision 2030, which boosts the need for reliable sealing solutions. In Africa, South Africa and Nigeria are key markets due to their mining and energy industries. Although challenges such as supply chain gaps and limited local manufacturing exist, the growing emphasis on industrial efficiency and equipment longevity supports steady demand for machined seals.

Machined Seals Market: Competitive Landscape

The report provides an in-depth analysis of companies operating in the machined seals market, including their geographic presence, business strategies, product offerings, market share, and recent developments. This analysis helps to understand market competition.

Some of the major players in the global machined seals market include:

- A.W. Chesterton Co.

- AB SKF

- AccroSeal

- Apple Rubber Products Inc.

- CARCO PRECISION RUBBER PRODUCTS S.P.A

- CTG Inc.

- Datwyler Holding Inc.

- EnPro Industries Inc.

- FedTech Inc.

- Flexaseal Engineered Seals and Systems LLC

- Freudenberg and Co. KG

- IDEX Corp.

- James Walker Group Ltd.

- MFPSeals

- Michelin Group

- Parker Hannifin Corp.

- Pawling Engineered Products Inc.

- SHV Holdings N.V.

- Trelleborg AB

- Vanguard Products Corp

The global machined seals market is segmented as follows:

By End-user

- Automotive industry

- Heavy industry

- Machine tools industry

- Others

By Type

- Fluid power seals

- Power transmission seals

- Large diameter seals

By Region

- North America

- U.S.

- Canada

- Europe

- U.K.

- France

- Germany

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia Pacific

- Latin America

- Brazil

- Rest of Latin America

- The Middle East and Africa

- GCC Countries

- South Africa

- Rest of Middle East Africa

Frequently Asked Questions

Table Of Content

Inquiry For Buying

Machined Seals

Request Sample

Machined Seals