Metal Nanoparticles Catalyst Market Size, Share, and Trends Analysis Report

CAGR :

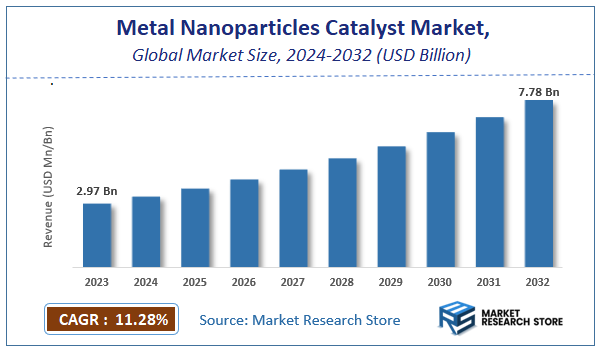

| Market Size 2023 (Base Year) | USD 2.97 Billion |

| Market Size 2032 (Forecast Year) | USD 7.78 Billion |

| CAGR | 11.28% |

| Forecast Period | 2024 - 2032 |

| Historical Period | 2018 - 2023 |

Metal Nanoparticles Catalyst Market Insights

According to Market Research Store, the global metal nanoparticles catalyst market size was valued at around USD 2.97 billion in 2023 and is estimated to reach USD 7.78 billion by 2032, to register a CAGR of approximately 11.28% in terms of revenue during the forecast period 2024-2032.

The metal nanoparticles catalyst report provides a comprehensive analysis of the market, including its size, share, growth trends, revenue details, and other crucial information regarding the target market. It also covers the drivers, restraints, opportunities, and challenges till 2032.

To Get more Insights, Request a Free Sample

Global Metal Nanoparticles Catalyst Market: Overview

Metal nanoparticles are particles composed of metals such as gold, silver, platinum, and copper, with sizes ranging from 1 to 100 nanometers. Due to their high surface area-to-volume ratio and unique electronic properties, they serve as efficient catalysts in various chemical reactions. These nanoparticles facilitate processes in industries like pharmaceuticals, petrochemicals, and environmental remediation by enhancing reaction rates and selectivity. For instance, in the pharmaceutical sector, metal nanoparticles are utilized in drug delivery systems and diagnostic tools, owing to their ability to interact at the cellular level. In environmental applications, they aid in the degradation of pollutants, contributing to cleaner technologies.

Key Highlights

- The metal nanoparticles catalyst market is anticipated to grow at a CAGR of 11.28% during the forecast period.

- The global metal nanoparticles catalyst market was estimated to be worth approximately USD 2.97 billion in 2023 and is projected to reach a value of USD 7.78 billion by 2032.

- The growth of the metal nanoparticles catalyst market is being driven by the increasing demand for efficient catalytic processes across various industries, including automotive, pharmaceuticals, and petrochemicals.

- Based on the type of metal, the silver nanoparticles segment is growing at a high rate and is projected to dominate the market.

- On the basis of catalyst functionality, the oxidation catalysts segment is projected to swipe the largest market share.

- In terms of application, the environmental segment is expected to dominate the market.

- Based on the Formulation, the supported catalysts segment is expected to dominate the market.

- Based on the industry vertical, the automotive segment is expected to dominate the market.

- By region, North America is expected to dominate the global market during the forecast period.

Metal Nanoparticles Catalyst Market: Dynamics

Key Growth Drivers:

- Enhanced Catalytic Activity: Metal nanoparticles exhibit significantly higher surface area-to-volume ratios compared to bulk materials. This leads to increased contact between the catalyst and reactants, boosting reaction rates and efficiency.

- Selectivity and Specificity: Precise control over nanoparticle size and shape allows for tailoring catalytic properties to specific reactions. This minimizes unwanted side products and improves the yield of desired products.

- Green Chemistry: Metal nanoparticle catalysts can enable greener chemical processes by reducing energy consumption, minimizing waste generation, and using milder reaction conditions.

- Emerging Applications: Expanding applications in fields like renewable energy (hydrogen production, fuel cells), environmental remediation (pollution control), and pharmaceuticals (drug delivery, diagnostics) drive market growth.

Restraints:

- High Production Costs: The synthesis and characterization of metal nanoparticles often involve complex and expensive techniques, limiting widespread adoption.

- Scalability Challenges: Scaling up production while maintaining consistent nanoparticle size, shape, and quality remains a significant hurdle.

- Safety Concerns: Potential environmental and health risks associated with the handling and disposal of nanoparticles require careful consideration and appropriate safety measures.

- Lack of Standardization: Variability in nanoparticle synthesis methods and characterization techniques can hinder reproducibility and hinder widespread adoption.

Opportunities:

- Advancements in Nanotechnology: Ongoing research and development in nanotechnology are leading to innovative synthesis methods, improved characterization techniques, and novel nanoparticle designs with enhanced catalytic properties.

- Growing Demand for Sustainable Solutions: Increasing global focus on environmental sustainability and renewable energy will drive demand for efficient and environmentally friendly catalysts.

- Emerging Applications in Biotechnology: Metal nanoparticles show promise in various biotechnological applications, such as biosensing, bioimaging, and targeted drug delivery.

- Collaboration and Partnerships: Collaboration between academia, industry, and government can accelerate research, development, and commercialization of metal nanoparticle catalysts.

Challenges:

- Regulatory Hurdles: The development and commercialization of nanomaterials often face regulatory challenges related to safety, environmental impact, and labeling.

- Intellectual Property: Protecting intellectual property related to novel nanoparticle catalysts can be complex and costly.

- Competition: Intense competition from established catalyst technologies and emerging alternative materials requires continuous innovation and differentiation.

- Public Perception: Addressing public concerns regarding the safety and potential risks associated with nanotechnology is crucial for market acceptance and growth.

Metal Nanoparticles Catalyst Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Metal Nanoparticles Catalyst Market |

| Market Size in 2023 | USD 2.97 Billion |

| Market Forecast in 2032 | USD 7.78 Billion |

| Growth Rate | CAGR of 11.28% |

| Number of Pages | 140 |

| Key Companies Covered | TOTO Corporation, KRONOS Worldwide, CRISTAL, TitanPE Technologies, OSAKA Titanium Technologies, Toshin, Evonik, DK Nano Technology, Zhejiang Harmony Photocatalytic Technology, Ishihara Sangyo Kaisha, Sakai Chemical, QuantumSphere, CDTi, Hyperion Catalysis International, Mach I, JIUSI |

| Segments Covered | By Product Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2023 |

| Forecast Year | 2024 to 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Metal Nanoparticles Catalyst Market: Segmentation Insights

The global metal nanoparticles catalyst market is divided by type of metal, catalyst functionality, application, formulation, industry vertical, and region.

Segmentation Insights by Type of Metal

Based on type of metal, the global metal nanoparticles catalyst market is divided into gold nanoparticles, silver nanoparticles, platinum nanoparticles, palladium nanoparticles, copper nanoparticles, and other.

In the metal nanoparticles catalyst market, silver nanoparticles are the most dominant segment. Their exceptional electrical conductivity and resistance to corrosion make them indispensable in the electrical and electronics industries. Additionally, silver nanoparticles exhibit significant antimicrobial properties, leading to their widespread use in healthcare applications, such as medical devices and antimicrobial coatings.

Following silver, gold nanoparticles hold a significant market share. Despite their higher cost, gold nanoparticles are valued for their stability and catalytic efficiency, particularly in oxidation reactions. They are extensively utilized in environmental catalysis, including air and water purification, and in the pharmaceutical sector for drug delivery systems and diagnostic tools, owing to their biocompatibility and unique optical properties.

Platinum nanoparticles also play a crucial role in the catalyst market, especially within the automotive and chemical industries. Known for their excellent catalytic activity, platinum nanoparticles are essential in applications such as catalytic converters and fuel cells. However, the high cost of platinum necessitates ongoing research to enhance their catalytic efficiency and durability through methods like alloying and surface modification.

Palladium nanoparticles share similarities with platinum in terms of catalytic properties and applications. They are highly effective in facilitating various chemical reactions, including hydrogenation and carbon-carbon coupling reactions. Palladium nanoparticles are extensively used in the pharmaceutical industry for the synthesis of complex organic molecules. Additionally, their application in fuel cells and other energy storage technologies is gaining traction, as they enhance the efficiency and durability of these systems.

Copper nanoparticles, while less dominant, are important in specific catalytic applications. They are effective in certain reduction reactions and are more cost-effective than many other metal nanoparticles. Copper nanoparticles are also explored for their potential in environmental catalysis and energy storage applications. The development of these less common metal nanoparticles is driven by the need for cost-effective and sustainable catalytic solutions.

Segmentation Insights by Catalyst Functionality

On the basis of catalyst functionality, the global metal nanoparticles catalyst market is bifurcated into oxidation catalysts, reduction catalysts, hydrogenation catalysts, and dehydrogenation catalysts.

In the realm of metal nanoparticle catalysts, oxidation catalysts stand out as the most dominant segment. These catalysts, often composed of metals like platinum, palladium, and gold, are pivotal in facilitating oxidation reactions across various industries. Their high catalytic efficiency makes them indispensable in applications such as automotive catalytic converters, where they play a crucial role in reducing harmful emissions by oxidizing carbon monoxide and unburned hydrocarbons into less harmful carbon dioxide and water. Additionally, in chemical manufacturing, oxidation catalysts are employed to produce essential chemicals like nitric acid and sulfuric acid, underscoring their significance in industrial processes.

Following closely are reduction catalysts, which are integral in processes that involve the gain of electrons or the decrease in oxidation state of molecules. Metal nanoparticles such as silver and copper are commonly used in these catalysts. A prominent application is in environmental remediation, where reduction catalysts aid in detoxifying pollutants. For instance, they facilitate the reduction of nitrogen oxides in automotive exhaust systems, thereby mitigating environmental pollution. In industrial settings, reduction catalysts are employed in processes like hydrodesulfurization, which is essential for removing sulfur compounds from crude oil during refining.

Hydrogenation catalysts occupy the next segment, with metals like platinum, palladium, and nickel nanoparticles being the primary constituents. These catalysts are vital in hydrogenation reactions, where hydrogen is added to compounds. A significant application is in the food industry, where hydrogenation catalysts are used to convert unsaturated fats to saturated fats, thereby solidifying oils to produce margarine and shortening. In the petrochemical industry, they play a crucial role in refining processes, such as the hydrogenation of alkenes to alkanes, enhancing fuel stability and quality.

Dehydrogenation catalysts, while less dominant, are essential in processes that involve the removal of hydrogen from molecules. Metal nanoparticles like platinum and chromium are commonly used in these catalysts. A key application is in the production of styrene from ethylbenzene, a process critical in the manufacturing of polystyrene plastics. Additionally, in the petrochemical industry, dehydrogenation catalysts are employed to convert alkanes to alkenes, which are valuable intermediates in the synthesis of various chemicals and polymers.

Segmentation Insights by Application

Based on application, the global metal nanoparticles catalyst market is divided into environmental applications, chemical production, petrochemical industry, pharmaceuticals, and electrochemistry.

In the metal nanoparticles catalyst market, environmental applications represent a significant segment. Metal nanoparticles are employed in environmental remediation processes, such as the catalytic reduction of pollutants in automotive exhaust systems and the treatment of industrial wastewater. Their high surface area and reactivity make them effective in breaking down harmful substances, contributing to pollution control and environmental protection.

In chemical production, metal nanoparticles serve as catalysts to enhance reaction rates and selectivity. They are utilized in the synthesis of various chemicals, including pharmaceuticals, agrochemicals, and polymers. The unique properties of metal nanoparticles, such as their tunable size and shape, allow for precise control over catalytic processes, leading to increased efficiency and yield in chemical manufacturing.

The petrochemical industry also benefits from metal nanoparticle catalysts, particularly in refining processes. They are used in hydrocracking and catalytic reforming to improve the quality of fuels and other petroleum products. The enhanced catalytic activity of metal nanoparticles facilitates the conversion of heavy hydrocarbons into lighter, more valuable fractions, optimizing the output of petrochemical refineries.

In the pharmaceutical sector, metal nanoparticles are increasingly applied in drug development and production. They act as catalysts in the synthesis of complex organic molecules, enabling the creation of active pharmaceutical ingredients with high purity and specificity. Additionally, metal nanoparticles are explored for targeted drug delivery systems and diagnostic applications, owing to their biocompatibility and unique physicochemical properties.

Electrochemistry is another area where metal nanoparticle catalysts are making an impact. They are integral components in the development of advanced energy storage and conversion devices, such as fuel cells and batteries. Metal nanoparticles enhance the electrochemical reactions within these devices, leading to improved performance, efficiency, and longevity.

Segmentation Insights by Formulation

On the basis of catalyst functionality, the global metal nanoparticles catalyst market is bifurcated into aqueous solutions, solvents-derived solutions, solid-state catalysts, and supported catalysts.

In the metal nanoparticles catalyst market, supported catalysts are the most dominant segment. These catalysts involve metal nanoparticles dispersed on support materials like silica, alumina, or carbon, enhancing their stability and catalytic efficiency. Supported catalysts are extensively utilized in various industrial processes, including petrochemical refining and chemical synthesis, due to their high activity and reusability.

Solid-state catalysts, comprising metal nanoparticles in a solid matrix, follow in prominence. They are employed in applications such as automotive catalytic converters and fuel cells, where their robustness and durability under high-temperature conditions are advantageous.

Aqueous solutions of metal nanoparticles are also significant, particularly in environmental and biomedical applications. In environmental remediation, these solutions facilitate the catalytic degradation of pollutants in water treatment processes. In the biomedical field, aqueous dispersions of metal nanoparticles are utilized for their catalytic properties in diagnostic assays and therapeutic treatments.

Solvent-derived solutions, where metal nanoparticles are dispersed in organic solvents, are less prevalent but find use in specialized chemical reactions. These formulations are applied in organic synthesis and catalysis, where the solvent environment can influence the reaction pathways and outcomes.

Segmentation Insights by Industry Vertical

On the basis of industry vertical, the global metal nanoparticles catalyst market is bifurcated into automotive, aerospace, electronics, energy, and food & beverage.

In the metal nanoparticles catalyst market, the automotive industry stands as the most dominant sector. This prominence is primarily due to the extensive use of metal nanoparticle catalysts in automotive catalytic converters, which are essential for reducing vehicle emissions and meeting stringent environmental regulations. The high surface area and unique properties of metal nanoparticles enhance the efficiency of these converters, making them indispensable in modern automotive applications.

Following the automotive sector, the electronics industry holds a significant share in the market. Metal nanoparticles are integral in the fabrication of electronic components, such as conductive inks, sensors, and capacitors, owing to their excellent electrical conductivity and miniaturization capabilities. Their application in printed electronics and the development of smaller, more efficient devices underscores their importance in this sector.

The energy industry also leverages metal nanoparticle catalysts, particularly in fuel cells and renewable energy technologies. These catalysts facilitate critical reactions, improving energy conversion efficiencies and contributing to the advancement of sustainable energy solutions.

In the aerospace sector, metal nanoparticles are utilized to develop lightweight and high-strength materials, enhancing fuel efficiency and performance of aircraft. Their catalytic properties are also explored in advanced propulsion systems, reflecting the sector's commitment to innovation and efficiency.

The food and beverage industry, while less dominant, employs metal nanoparticle catalysts in processes such as hydrogenation of oils and fats, which is crucial for producing margarine and shortening. Additionally, their antimicrobial properties are harnessed in packaging materials to extend shelf life and ensure food safety.

Metal Nanoparticles Catalyst Market: Regional Insights

- North America is expected to dominates the global market

North America holds a substantial share of the metal nanoparticles catalyst market, primarily due to the presence of major pharmaceutical, petrochemical, and automotive industries. The United States, in particular, is a major contributor, with a strong focus on innovation and technological advancements. The region's well-developed industrial infrastructure, high consumer purchasing power, and emphasis on sustainability contribute to market growth. The increasing demand for advanced catalytic solutions in pharmaceuticals, petrochemicals, and emission control systems further supports the adoption of metal nanoparticles catalysts in North America. Additionally, advancements in nanoparticle synthesis methods and the integration of advanced technologies enhance the performance and efficiency of these catalysts.

Europe is another prominent market for metal nanoparticles catalysts, with countries such as Germany, France, and the United Kingdom leading the adoption. The region's well-established pharmaceutical and petrochemical industries, coupled with a strong focus on sustainability, drive the demand for these catalysts. Increasing investments in research and development activities and the growing demand for innovative and sustainable chemical products support market growth. The presence of key market players and strategic collaborations with research institutions and industry stakeholders further enhance the market's growth in Europe.

Asia-Pacific is a rapidly growing market for metal nanoparticles catalysts, driven by increasing industrialization and infrastructure development in countries such as China, India, and Japan. The region's expanding pharmaceutical and petrochemical sectors, along with a rising focus on environmental sustainability, contribute to the demand for advanced catalytic solutions. Government initiatives supporting industrial growth and environmental protection further bolster the adoption of metal nanoparticles catalysts in this region. Additionally, the availability of raw materials and cost-effective manufacturing processes provide a competitive advantage to Asia-Pacific in the global market.

Latin America and the Middle East & Africa regions are experiencing gradual growth in the metal nanoparticles catalyst market. In Latin America, countries like Brazil and Mexico are witnessing increased industrial activities, leading to a rising demand for efficient catalytic processes in the petrochemical and automotive sectors. Similarly, in the Middle East & Africa, the expansion of the petrochemical industry and growing environmental concerns are driving the adoption of advanced catalyst technologies. However, factors such as economic instability and limited technological advancements pose challenges to market growth in these regions.

Metal Nanoparticles Catalyst Market: Competitive Landscape

The report provides an in-depth analysis of companies operating in the metal nanoparticles catalyst market, including their geographic presence, business strategies, product offerings, market share, and recent developments. This analysis helps to understand market competition.

Some of the major players in the global metal nanoparticles catalyst market include:

- TOTO Corporation

- KRONOS Worldwide

- CRISTAL

- TitanPE Technologies

- OSAKA Titanium Technologies

- Toshin

- Evonik

- DK Nano Technology

- Zhejiang Harmony Photocatalytic Technology

- Ishihara Sangyo Kaisha

- Sakai Chemical

- QuantumSphere

- CDTi

- Hyperion Catalysis International

- Mach I

- JIUSI

The global metal nanoparticles catalyst market is segmented as follows:

By Type of Metal

- Gold Nanoparticles

- Silver Nanoparticles

- Platinum Nanoparticles

- Palladium Nanoparticles

- Copper Nanoparticles

- Other

By Catalyst Functionality

- Oxidation Catalysts

- Reduction Catalysts

- Hydrogenation Catalysts

- Dehydrogenation Catalysts

By Application

- Environmental Applications

- Chemical Production

- Petrochemical Industry

- Pharmaceuticals

- Electrochemistry

By Formulation

- Aqueous Solutions

- Solvents-Derived Solutions

- Solid-State Catalysts

- Supported Catalysts

By Industry Vertical

- Automotive

- Aerospace

- Electronics

- Energy

- Food and Beverage

By Region

- North America

- U.S.

- Canada

- Europe

- U.K.

- France

- Germany

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia Pacific

- Latin America

- Brazil

- Rest of Latin America

- The Middle East and Africa

- GCC Countries

- South Africa

- Rest of Middle East Africa

Frequently Asked Questions

Based on statistics from the Market Research Store, the global metal nanoparticles catalyst market size was projected at approximately US$ 2.97 billion in 2023. Projections indicate that the market is expected to reach around US$ 7.78 billion in revenue by 2032.

The global metal nanoparticles catalyst market is expected to grow at a Compound Annual Growth Rate (CAGR) of around 11.28% during the forecast period from 2024 to 2032.

North America is expected to dominate the global metal nanoparticles catalyst market.

The global metal nanoparticles catalyst market is primarily driven by the increasing demand for efficient catalytic processes across various industries, including automotive, pharmaceuticals, and petrochemicals.

Some of the prominent players operating in the global metal nanoparticles catalyst market are; TOTO Corporation, KRONOS Worldwide, CRISTAL, TitanPE Technologies, OSAKA Titanium Technologies, Toshin, Evonik, DK Nano Technology, Zhejiang Harmony Photocatalytic Technology, Ishihara Sangyo Kaisha, Sakai Chemical, QuantumSphere, CDTi, Hyperion Catalysis International, Mach I, JIUSI, and others.

Table Of Content

Inquiry For Buying

Metal Nanoparticles Catalyst

Request Sample

Metal Nanoparticles Catalyst