Nickel-Titanium Shape Memory Alloys Market Size, Share, and Trends Analysis Report

CAGR :

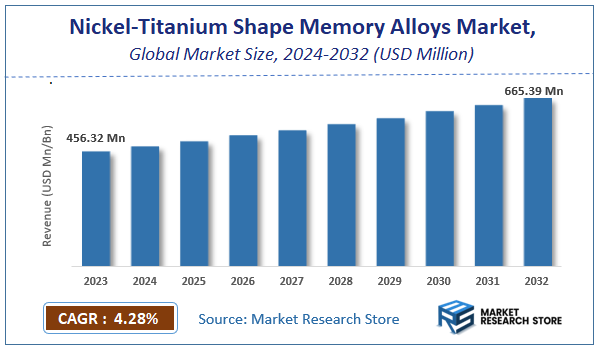

| Market Size 2023 (Base Year) | USD 456.32 Million |

| Market Size 2032 (Forecast Year) | USD 665.39 Million |

| CAGR | 4.28% |

| Forecast Period | 2024 - 2032 |

| Historical Period | 2018 - 2023 |

Nickel-Titanium Shape Memory Alloys Market Insights

According to Market Research Store, the global nickel-titanium shape memory alloys market size was valued at around USD 456.32 million in 2023 and is estimated to reach USD 665.39 million by 2032, to register a CAGR of approximately 4.28% in terms of revenue during the forecast period 2024-2032.

The nickel-titanium shape memory alloys report provides a comprehensive analysis of the market, including its size, share, growth trends, revenue details, and other crucial information regarding the target market. It also covers the drivers, restraints, opportunities, and challenges till 2032.

To Get more Insights, Request a Free Sample

Global Nickel-Titanium Shape Memory Alloys Market: Overview

Nickel-Titanium Shape Memory Alloys (NiTi SMAs), also known as Nitinol, are a group of metallic alloys primarily composed of nickel and titanium. These materials are renowned for their unique property of undergoing a phase transition between two solid states, austenite and martensite, which allows them to "remember" a specific shape. When deformed at lower temperatures, they can revert to their original shape when heated above a certain threshold, a phenomenon called the shape memory effect. Additionally, NiTi alloys exhibit super elasticity, enabling them to return to their original shape even after significant deformation at room temperature.

The Nickel-Titanium Shape Memory Alloys market has been experiencing significant growth due to their wide-ranging applications across several industries, including medical devices, automotive, aerospace, and robotics. In medical devices, NiTi alloys are commonly used in stents, guidewires, orthodontic devices, and catheters, owing to their biocompatibility and excellent mechanical properties. The automotive sector utilizes NiTi alloys for components like sensors, actuators, and eyeglasses for their lightweight, corrosion-resistant, and reliable performance. The aerospace industry also employs them for actuators and precision components due to their ability to operate under extreme conditions.

Key Highlights

- The nickel-titanium shape memory alloys market is anticipated to grow at a CAGR of 4.28% during the forecast period.

- The global nickel-titanium shape memory alloys market was estimated to be worth approximately USD 456.32 million in 2023 and is projected to reach a value of USD 665.39 million by 2032.

- The growth of the nickel-titanium shape memory alloys market is being driven by [content].

- Based on the product, the high temperature austenite phase segment is growing at a high rate and is projected to dominate the market.

- On the basis of application, the medical applications segment is projected to swipe the largest market share.

- By region, North America is expected to dominate the global market during the forecast period.

Nickel-Titanium Shape Memory Alloys Market: Dynamics

Key Growth Drivers

- Medical Applications Stents: Widely used in cardiovascular medicine for treating coronary artery disease and peripheral vascular disease.

- Aerospace & Defense: Used in aircraft and aerospace applications for actuators, sensors, and other components due to their high strength-to-weight ratio and shape memory properties.

- Automotive: Employed in automotive applications like engine mounts, suspension systems, and safety devices, enhancing vehicle performance and safety.

- Consumer Electronics: Increasingly used in consumer electronics, such as actuators in mobile phones, cameras, and other devices.

Restraints

- High Production Costs: The production of high-quality nickel-titanium alloys requires specialized processing techniques and can be expensive.

- Complex Manufacturing Processes: The intricate manufacturing processes involved in shaping and processing nickel-titanium alloys can be complex and challenging.

- Potential for Fatigue and Corrosion: While durable, nickel-titanium alloys can exhibit fatigue and corrosion under certain conditions, which can limit their long-term performance.

- Regulatory Challenges: Compliance with stringent regulatory requirements related to medical device safety and performance can be a significant challenge, particularly in the medical device industry.

Opportunities

- Development of Novel Alloys: Research and development of novel nickel-titanium alloys with improved properties, such as enhanced corrosion resistance, biocompatibility, and fatigue resistance.

- Exploring New Applications: Exploring new and emerging applications for nickel-titanium alloys, such as in robotics, energy harvesting, and smart materials.

- Focus on Sustainability: Emphasizing sustainable production practices, including the recycling and reuse of nickel-titanium alloys.

- Collaboration with Research Institutions: Collaborating with research institutions to advance the understanding of nickel-titanium alloys and develop new and innovative applications.

Challenges

- Maintaining Product Quality and Consistency: Ensuring consistent quality and performance across different production batches and meeting the stringent requirements of various applications.

- Addressing Environmental Concerns: Mitigating the environmental impact of nickel-titanium alloy production and end-of-life disposal.

- Staying Competitive: Remaining competitive in a dynamic market with increasing competition from other advanced materials.

- Meeting Evolving Regulatory Requirements: Complying with evolving regulatory requirements related to safety, performance, and environmental sustainability.

Nickel-Titanium Shape Memory Alloys Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Nickel-Titanium Shape Memory Alloys Market |

| Market Size in 2023 | USD 456.32 Million |

| Market Forecast in 2032 | USD 665.39 Million |

| Growth Rate | CAGR of 4.28% |

| Number of Pages | 140 |

| Key Companies Covered | Nitinol Devices & Components, SAES Getters, G.RAU GmbH & Co. KG, ATI Wah-chang, Johnson Matthey, Fort Wayne Metals, Furukawa Electric, Nippon Steel & Sumitomo Metal, Nippon Seisen, Metalwerks PMD, Ultimate NiTi Technologies, Dynalloy, Grikin, PEIER Tech, Saite Metal, Smart, Baoji Seabird Metal, GEE |

| Segments Covered | By Product Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2023 |

| Forecast Year | 2024 to 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Nickel-Titanium Shape Memory Alloys Market: Segmentation Insights

The global nickel-titanium shape memory alloys market is divided by product, application, and region.

Segmentation Insights by Product

Based on product, the global nickel-titanium shape memory alloys market is divided into high temperature austenite phase and low temperature martensite phase.

The High Temperature Austenite Phase segment dominates the Nickel-Titanium Shape Memory Alloys Market due to its extensive application in medical devices, aerospace, and industrial automation. This phase is characterized by its ability to return to its original shape upon heating, making it ideal for stents, guidewires, orthodontic archwires, and actuator systems in high-performance industries. The growing demand for minimally invasive medical procedures and advanced aerospace components drives the adoption of high-temperature austenite phase alloys.

The Low Temperature Martensite Phase segment holds a significant market share, particularly in applications requiring flexibility, damping capacity, and superelasticity at lower temperatures. These alloys are widely used in robotics, consumer electronics, and safety systems, where controlled deformation and shape retention are critical. Although it has a substantial presence in specialized sectors, its adoption is comparatively lower than the austenite phase due to specific temperature constraints and application limitations.

Segmentation Insights by Application

On the basis of application, the global nickel-titanium shape memory alloys market is bifurcated into medical applications, aircraft applications, automotive, and home appliance.

The Medical Applications segment dominates the Nickel-Titanium Shape Memory Alloys Market due to the widespread use of these alloys in minimally invasive surgical devices, stents, guidewires, orthodontic archwires, and orthopedic implants. The superior biocompatibility, superelasticity, and shape memory properties of Ni-Ti alloys make them ideal for applications in medical treatments, particularly in cardiovascular and orthopedic surgeries. The growing demand for advanced medical technologies and an aging population requiring surgical interventions further drive the adoption of these alloys in the healthcare sector.

The Aircraft Applications segment holds a significant market share, particularly in aerospace components requiring high fatigue resistance, lightweight materials, and thermal adaptability. These alloys are used in actuators, morphing wings, and vibration control systems, offering enhanced performance and energy efficiency in modern aircraft. With increasing investments in next-generation aerospace technologies, the demand for Ni-Ti alloys in aviation is expected to grow.

The Automotive segment also represents a key market, with applications in smart actuators, sensors, and adaptive structures for improved vehicle efficiency, fuel economy, and safety. The growing shift towards electric and autonomous vehicles is driving the integration of shape memory alloys in advanced automotive components.

The Home Appliance segment is emerging, with applications in thermostatic valves, energy-efficient controls, and responsive actuators in smart home technologies. The adoption of Ni-Ti alloys in this sector is driven by increasing demand for automation and intelligent home systems.

Nickel-Titanium Shape Memory Alloys Market: Regional Insights

- North America is expected to dominates the global market

North America holds a significant share in the nickel-titanium shape memory alloys market, led by the United States and Canada. The region’s strong medical device industry, particularly in orthopedic and cardiovascular implants, is a major driver of demand. Additionally, increasing investments in aerospace, robotics, and defense applications contribute to market growth. The presence of key manufacturers and research institutions further strengthens the market’s expansion.

Europe is a key market, with Germany, France, and the UK leading in adoption. The region benefits from a well-established medical technology sector, along with significant demand for NiTi alloys in automotive and aerospace applications. The increasing use of smart materials in robotics and industrial automation also drives growth. Additionally, stringent EU regulations promoting biocompatible and corrosion-resistant materials support demand for NiTi alloys in medical implants.

Asia-Pacific is the fastest-growing region in the nickel-titanium shape memory alloys market, driven by China, Japan, and South Korea. The region's rapidly expanding medical device industry, increasing use of smart materials in robotics and industrial automation, and rising demand for high-performance alloys in aerospace applications contribute to market growth. China’s focus on developing advanced manufacturing technologies and Japan’s leadership in robotics further accelerate the adoption of NiTi alloys.

Latin America is an emerging market, with Brazil and Mexico leading in adoption. The increasing demand for medical implants, expanding industrial manufacturing sector, and growing interest in advanced materials contribute to market growth. However, limited local production capabilities and high costs of NiTi alloys may restrain widespread adoption.

Middle East and Africa region is gradually expanding in the NiTi shape memory alloys market, with the UAE and South Africa showing increased interest in medical applications and industrial automation. The growing demand for high-performance materials in aerospace and oil & gas industries also supports market growth. However, limited manufacturing infrastructure and higher costs may slow adoption in certain regions.

Nickel-Titanium Shape Memory Alloys Market: Competitive Landscape

The report provides an in-depth analysis of companies operating in the nickel-titanium shape memory alloys market, including their geographic presence, business strategies, product offerings, market share, and recent developments. This analysis helps to understand market competition.

Some of the major players in the global nickel-titanium shape memory alloys market include:

- ATI Wah-chang

- Baoji Seabird Metal

- Dynalloy

- Fort Wayne Metals

- Furukawa Electric

- G.RAU GmbH & Co. KG

- GEE

- Grikin

- Johnson Matthey

- Metalwerks PMD

- Nippon Seisen

- Nippon Steel & Sumitomo Metal

- Nitinol Devices & Components

- PEIER Tech

- SAES Getters

- Saite Metal

- Smart

- Ultimate NiTi Technologies

The global nickel-titanium shape memory alloys market is segmented as follows:

By Product

- High Temperature Austenite Phase

- Low Temperature Martensite Phase

By Application

- Medical Applications

- Aircraft Applications

- Automotive

- Home Appliance

- Others

By Region

- North America

- U.S.

- Canada

- Europe

- U.K.

- France

- Germany

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia Pacific

- Latin America

- Brazil

- Rest of Latin America

- The Middle East and Africa

- GCC Countries

- South Africa

- Rest of Middle East Africa

Frequently Asked Questions

Based on statistics from the Market Research Store, the global nickel-titanium shape memory alloys market size was projected at approximately US$ 456.32 million in 2023. Projections indicate that the market is expected to reach around US$ 665.39 million in revenue by 2032.

The global nickel-titanium shape memory alloys market is expected to grow at a Compound Annual Growth Rate (CAGR) of around 4.28% during the forecast period from 2024 to 2032.

North America is expected to dominate the global nickel-titanium shape memory alloys market.

The global nickel-titanium shape memory alloys market is driven by several factors, including increasing demand for advanced materials in medical devices, aerospace applications, and consumer electronics.

Some of the prominent players operating in the global nickel-titanium shape memory alloys market are; ATI Wah-chang, Baoji Seabird Metal, Dynalloy, Fort Wayne Metals, Furukawa Electric, G.RAU GmbH & Co. KG, GEE, Grikin, Johnson Matthey, Metalwerks PMD, Nippon Seisen, Nippon Steel & Sumitomo Metal, Nitinol Devices & Components, PEIER Tech, SAES Getters, Saite Metal, Smart, Ultimate NiTi Technologies, and others.

Table Of Content

Inquiry For Buying

Nickel-Titanium Shape Memory Alloys

Request Sample

Nickel-Titanium Shape Memory Alloys