Single-Pass Digital Textile Printing Machine Market Size, Share, and Trends Analysis Report

CAGR :

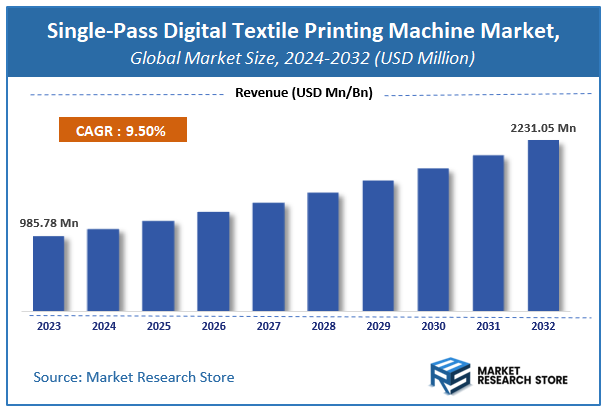

| Market Size 2023 (Base Year) | USD 985.78 Million |

| Market Size 2032 (Forecast Year) | USD 2231.05 Million |

| CAGR | 9.5% |

| Forecast Period | 2024 - 2032 |

| Historical Period | 2018 - 2023 |

Single-Pass Digital Textile Printing Machine Market Insights

According to Market Research Store, the global single-pass digital textile printing machine market size was valued at around USD 985.78 million in 2023 and is estimated to reach USD 2231.05 million by 2032, to register a CAGR of approximately 9.5% in terms of revenue during the forecast period 2024-2032.

The single-pass digital textile printing machine report provides a comprehensive analysis of the market, including its size, share, growth trends, revenue details, and other crucial information regarding the target market. It also covers the drivers, restraints, opportunities, and challenges till 2032.

To Get more Insights, Request a Free Sample

Global Single-Pass Digital Textile Printing Machine Market: Overview

The Single-Pass Digital Textile Printing Machine Market focuses on advanced printing equipment designed for high-speed, high-volume textile production. Unlike traditional multi-pass printers, single-pass digital textile printers complete the printing process in a single run, significantly increasing efficiency and reducing production time. These machines are widely used in the fashion, home décor, and industrial textile sectors, where speed, precision, and vibrant color reproduction are essential. Single-pass digital textile printers are capable of handling various fabrics, including cotton, polyester, silk, and blends, making them versatile for different applications.

The market is driven by the growing demand for customized and on-demand textile printing, particularly in the fashion and home décor industries. The rise of fast fashion and the need for sustainable production methods have further fueled the adoption of single-pass digital textile printing machines. Additionally, advancements in inkjet technology, such as improved printheads and eco-friendly inks, have enhanced print quality and durability, making these machines more appealing. However, challenges such as high initial costs and the need for skilled operators may hinder market growth.

Key Highlights

- The single-pass digital textile printing machine market is anticipated to grow at a CAGR of 9.5% during the forecast period.

- The global single-pass digital textile printing machine market was estimated to be worth approximately USD 985.78 million in 2023 and is projected to reach a value of USD 2231.05 million by 2032.

- The growth of the single-pass digital textile printing machine market is being driven by the increasing demand for high-speed, high-volume textile printing solutions, coupled with the rising need for customization and on-demand production.

- Based on the technology type, the inkjet printing segment is growing at a high rate and is projected to dominate the market.

- On the basis of ink type, the reactive dyes segment is projected to swipe the largest market share.

- In terms of application, the apparel segment is expected to dominate the market.

- Based on the end-user, the textile manufacturers segment is expected to dominate the market.

- Based on the machine width, the below by 8 meters segment is expected to dominate the market.

- By region, North America is expected to dominate the global market during the forecast period.

Single-Pass Digital Textile Printing Machine Market: Dynamics

Key Drivers

- High-Speed Production: Single-pass technology enables extremely fast printing, crucial for high-volume textile production, like fast fashion and home textiles.

- On-Demand and Customized Production: Digital printing allows for variable data printing, facilitating personalized designs and short-run production.

- Reduced Time-to-Market: Faster production speeds and on-demand printing reduce lead times and accelerate product launches.

- Sustainability: Digital printing reduces water and energy consumption compared to traditional textile printing methods.

- Design Flexibility: Digital printing allows for intricate designs and unlimited color options, expanding creative possibilities.

Restraints

- High Initial Investment: Single-pass textile machines are expensive, limiting adoption by smaller textile businesses.

- Technical Complexity: Operating and maintaining these machines requires specialized expertise and training.

- Limited Fabric Versatility: Some single-pass machines may have limitations in the types of fabrics they can handle.

- High Maintenance Costs: The complex nature of these machines can lead to higher maintenance costs.

- Ink Costs: Ink costs, particularly for specialized textile inks, can be a significant operational expense.

Opportunities

- Fast Fashion and Mass Customization: Meeting the growing demand for fast fashion and personalized apparel with high-speed digital printing.

- Home Textiles and Décor: Expanding into home textiles and décor applications, offering customized designs for curtains, upholstery, and bedding.

- Technical Textiles: Exploring applications in technical textiles, such as sportswear, automotive textiles, and industrial fabrics.

- Sustainable Textile Production: Promoting sustainable textile printing practices by reducing water and energy consumption.

- Expansion into Emerging Markets: Growing textile industries in emerging markets present significant opportunities for single-pass digital printing.

Challenges

- Maintaining Print Quality at High Speeds: Ensuring consistent print quality and color accuracy at extremely high speeds is a key challenge.

- Managing Data Processing and Workflow: Handling the large volumes of data required for high-speed textile printing requires robust data processing and workflow management systems.

- Addressing Fabric Compatibility: Developing machines that can handle a wider range of fabrics, including delicate and textured materials, is essential.

- Managing Ink Consumption and Costs: Optimizing ink usage and reducing ink costs are crucial for improving profitability.

- Keeping Up with Technological Advancements: Adapting to rapid advancements in digital textile printing technology and maintaining a competitive edge is a continuous challenge.

- Colorfastness and Durability: Ensuring proper colorfastness and durability of prints on various fabric types.

Single-Pass Digital Textile Printing Machine Market: Report Scope

This report thoroughly analyzes the Single-Pass Digital Textile Printing Machine Market, exploring its historical trends, current state, and future projections. The market estimates presented result from a robust research methodology, incorporating primary research, secondary sources, and expert opinions. These estimates are influenced by the prevailing market dynamics as well as key economic, social, and political factors. Furthermore, the report considers the impact of regulations, government expenditures, and advancements in research and development on the market. Both positive and negative shifts are evaluated to ensure a comprehensive and accurate market outlook.

| Report Attributes | Report Details |

|---|---|

| Report Name | Single-Pass Digital Textile Printing Machine Market |

| Market Size in 2023 | USD 985.78 Million |

| Market Forecast in 2032 | USD 2231.05 Million |

| Growth Rate | CAGR of 9.5% |

| Number of Pages | 185 |

| Key Companies Covered | Dover, Atexco, EFI, Konica Minolta, SPGPrints |

| Segments Covered | By Technology Type, By Ink Type, By Application, By End-User, By Machine Width, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2023 |

| Forecast Year | 2024 to 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Single-Pass Digital Textile Printing Machine Market: Segmentation Insights

The global single-pass digital textile printing machine market is divided by technology type, ink type, application, end-user, machine width, and region.

Segmentation Insights by Technology Type

Based on technology type, the global single-pass digital textile printing machine market is divided into inkjet printing, direct to garment (DTG) printing, and hybrid printing technologies.

Inkjet Printing segment dominates the market due to its high-speed, cost-effective printing capabilities across various textile applications. Inkjet technology, particularly in single-pass digital textile printing, enables precise, high-resolution prints with vibrant colors and minimal ink wastage. This segment is widely adopted in fashion, home textiles, and industrial fabrics, where large-scale production and fast turnaround are critical. The demand for sustainable, water-based inks and eco-friendly printing solutions further strengthens the dominance of inkjet technology in the digital textile printing sector.

Direct to Garment (DTG) Printing segment holds a significant share, particularly in the customization and on-demand printing markets. DTG technology is widely used in apparel printing, allowing detailed, full-color prints directly onto garments such as t-shirts, hoodies, and sportswear. The ability to print on cotton and cotton-blend fabrics with minimal setup makes DTG a preferred choice for small-scale businesses, e-commerce platforms, and personalized fashion brands. The increasing demand for mass customization, coupled with advancements in pre-treatment and drying technologies, is driving the expansion of DTG printing.

Hybrid Printing Technologies segment is gaining traction, combining digital inkjet printing with traditional screen printing or other finishing techniques. This segment is particularly useful for businesses that require a mix of high-speed production and specialty effects such as metallic finishes, embossing, or textured prints. Hybrid printing is increasingly being adopted in the luxury fashion and high-end home décor markets, where unique designs and premium-quality prints are essential.

Segmentation Insights by Ink Type

On the basis of ink type, the global single-pass digital textile printing machine market is bifurcated into reactive dyes, acid dyes, disperse dyes, and pigment inks.

Reactive Dyes segment dominates the market, primarily due to its widespread application in cotton and cellulosic fiber printing. Reactive dyes chemically bond with fibers, providing excellent wash fastness, vibrant colors, and long-lasting durability. This ink type is extensively used in the fashion industry, home textiles, and upholstery, where high-quality prints with deep penetration and color vibrancy are essential. The growing demand for sustainable and eco-friendly printing solutions also drives the adoption of reactive dyes, as they are compatible with water-based formulations.

Acid Dyes segment holds a significant share, catering mainly to silk, wool, and nylon textile applications. Acid dyes offer exceptional brightness, color depth, and wash resistance, making them the preferred choice for luxury apparel, high-end fashion, and performance textiles such as swimwear and activewear. The increasing demand for premium textile printing, especially in the high-fashion and lingerie industries, supports the growth of this segment.

Disperse Dyes segment is expanding, particularly in the polyester textile printing market. This dye type provides excellent color fastness and durability, making it ideal for sportswear, technical textiles, and synthetic fabrics. The growing use of polyester-based textiles in athleisure, outdoor gear, and automotive interiors is fueling the demand for disperse dyes in single-pass digital textile printing. Sublimation printing, a key application of disperse dyes, is also witnessing strong growth due to its ability to produce high-definition prints with superior color retention.

Pigment Inks segment is gaining traction due to its versatility and ability to print on multiple fabric types without requiring complex pre- or post-treatment processes. Pigment inks provide high color accuracy, sharp details, and water resistance, making them suitable for direct-to-garment (DTG) printing, home textiles, and customized fashion. Additionally, pigment-based digital printing is increasingly favored for its eco-friendly nature, as it requires less water and energy compared to traditional dye-based printing.

Segmentation Insights by Application

On the basis of application, the global single-pass digital textile printing machine market is bifurcated into apparel, home textiles, fashion textiles, and industrial textiles.

Apparel segment dominates the market, driven by the growing demand for customized, on-demand, and fast-fashion clothing. Single-pass digital textile printing enables high-speed, high-resolution printing with vibrant colors, making it ideal for mass-producing t-shirts, activewear, sportswear, and casual apparel. The adoption of digital printing in apparel manufacturing is further fueled by the rise of e-commerce, personalized clothing trends, and sustainability initiatives, as digital printing reduces water and fabric waste compared to traditional methods.

Home Textiles segment holds a significant share, primarily due to the increasing preference for digitally printed bedding, curtains, upholstery, and decorative fabrics. The ability to produce intricate designs with high color accuracy and minimal environmental impact has made digital textile printing a preferred choice for home textile manufacturers. Growing urbanization, rising consumer spending on interior décor, and the demand for sustainable printing solutions are key factors driving the growth of this segment.

Fashion Textiles segment is expanding, particularly in high-end and luxury fashion markets. Designers and fashion brands are increasingly utilizing single-pass digital printing for limited-edition collections, customized prints, and high-resolution graphics on fabrics such as silk, chiffon, and premium cotton. The flexibility of digital textile printing in producing unique, complex designs with a quick turnaround time is revolutionizing the fashion industry, reducing dependence on traditional screen printing methods.

Industrial Textiles segment is growing steadily, with applications in automotive, medical, technical, and functional textiles. Digital printing is used for printing on performance fabrics, industrial protective wear, and specialized materials that require durability, resistance to extreme conditions, and high-quality graphic detailing. The increasing use of digitally printed textiles in sectors such as automotive interiors, medical textiles, and protective gear is contributing to the steady growth of this segment.

Segmentation Insights by End-User

On the basis of end-user, the global single-pass digital textile printing machine market is bifurcated into textile manufacturers, fashion designers, print service providers (PSPs), and retail brands.

Textile Manufacturers segment dominates the market, driven by the increasing adoption of digital printing for high-speed, large-scale textile production. Single-pass digital textile printing enables manufacturers to produce high-quality prints with faster turnaround times, reduced water usage, and minimal fabric waste. The growing demand for sustainable textile printing and mass customization in industries such as apparel, home textiles, and industrial fabrics further strengthens this segment's dominance.

Fashion Designers segment holds a significant share, particularly in the luxury and high-end fashion industry. Digital textile printing allows designers to experiment with intricate patterns, vibrant colors, and personalized prints without the limitations of traditional screen printing. The ability to quickly produce limited-edition designs and exclusive collections enhances the appeal of single-pass digital printing for fashion designers, supporting market growth in this segment.

Print Service Providers (PSPs) segment is expanding as digital printing becomes more accessible and cost-effective. PSPs cater to businesses and individuals seeking high-quality textile printing for various applications, including custom apparel, promotional products, and interior décor. The rising demand for short-run production, on-demand printing, and e-commerce-driven customization is fueling the adoption of single-pass digital textile printers among PSPs.

Retail Brands segment is gaining traction as major clothing and home décor brands integrate digital printing technology into their supply chains. Retail brands are leveraging digital printing for in-house production, enabling faster response to changing fashion trends and reducing excess inventory. The ability to offer personalized and limited-edition products is also driving the adoption of single-pass digital textile printing in the retail sector.

Segmentation Insights by Machine Width

On the basis of machine width, the global single-pass digital textile printing machine market is bifurcated into below by 8 meters, by 8 to 3 meters, and above 3 meters.

Below 8 Meters segment dominates the market in applications requiring small-scale, high-precision textile printing. These machines are preferred for fashion designers, print service providers (PSPs), and boutique textile manufacturers that focus on customized apparel, home textiles, and promotional items. Their compact size and cost-effectiveness make them ideal for small-batch production, direct-to-garment (DTG) printing, and personalized textile applications.

8 to 3 Meters segment holds a significant share, catering to medium- to large-scale textile manufacturers and commercial print shops. This range is commonly used for printing home décor fabrics, soft signage, banners, and roll-to-roll textile applications. These machines offer a balance between high-speed production and flexibility, making them suitable for fashion and interior textile printing where larger fabric widths are required without excessive material wastage.

Above 3 Meters segment is expanding, primarily driven by demand from industrial textile manufacturers and large-scale fabric printing operations. These machines are designed for mass production of textiles used in upholstery, technical textiles, and wide-format applications such as large-scale home textiles, automotive interiors, and industrial fabrics. Their ability to print high volumes with consistent quality and efficiency makes them a preferred choice for large-scale commercial operations.

Single-Pass Digital Textile Printing Machine Market: Regional Insights

- North America is expected to dominate the global market.

North America dominates the Single-Pass Digital Textile Printing Machine Market due to the strong presence of the fashion, home décor, and technical textiles industries. The United States leads the region, driven by increasing demand for customized and on-demand textile printing, particularly in apparel and soft signage applications. The rapid adoption of digital printing in sustainable textile production, coupled with advancements in pigment and reactive dye-based printing, is further fueling market expansion. Canada is also witnessing steady growth due to the increasing demand for eco-friendly textile printing solutions and the expansion of the digital textile printing industry.

Europe holds a significant share of the market, supported by its strong textile and fashion industries, stringent environmental regulations, and advancements in digital printing technology. Italy, Germany, and the UK are key contributors. Italy leads the region with its well-established textile manufacturing sector and widespread adoption of high-speed digital printing solutions for luxury fashion and home textiles. Germany is witnessing rapid growth in the technical textiles segment, where digital printing is used for sportswear, automotive fabrics, and medical textiles. The UK is focusing on sustainable textile printing, with increasing investments in water-based ink and eco-friendly production processes. The European Union’s regulations on reducing water and chemical waste in textile production are also driving the adoption of single-pass digital printing machines.

Asia Pacific is the fastest-growing region in the Single-Pass Digital Textile Printing Machine Market, driven by rapid industrialization, increasing textile production, and growing demand for digitally printed fabrics. China, India, Japan, and South Korea are key markets. China leads the region with its large-scale textile industry, high export demand, and government support for digital textile printing technologies. The country is witnessing significant adoption of single-pass digital printing for fashion textiles, home décor, and sportswear manufacturing. India is experiencing strong growth due to the expansion of its garment and textile printing industry, driven by rising domestic demand and exports. Japan is focusing on high-precision inkjet printing technology, particularly for technical and specialty textiles. South Korea is leveraging digital printing in performance fabrics and smart textiles, driving demand for advanced single-pass machines.

Latin America is experiencing moderate market growth, with Brazil and Mexico leading the region. Brazil’s growing textile and fashion industries are driving demand for high-speed digital textile printing solutions. Mexico is witnessing increased adoption of single-pass digital textile printing in apparel manufacturing and home textiles. However, economic fluctuations and high initial investment costs may limit market expansion in some areas.

The Middle East & Africa is gradually adopting digital textile printing technology, particularly in the UAE, Saudi Arabia, and South Africa. The UAE and Saudi Arabia are investing in digital textile printing for luxury fashion, traditional garments, and home furnishings, driving market demand. South Africa is witnessing steady adoption in the textile and apparel sectors, with a growing focus on sustainable production methods. However, limited technological infrastructure in some parts of the region may slow overall market growth.

Single-Pass Digital Textile Printing Machine Market: Competitive Landscape

The report provides an in-depth analysis of companies operating in the single-pass digital textile printing machine market, including their geographic presence, business strategies, product offerings, market share, and recent developments. This analysis helps to understand market competition.

Some of the major players in the global single-pass digital textile printing machine market include:

- Dover

- Atexco

- EFI

- Konica Minolta

- SPGPrints

The global single-pass digital textile printing machine market is segmented as follows:

By Technology Type

- Inkjet Printing

- Direct to Garment (DTG) Printing

- Hybrid Printing Technologies

By Ink Type

- Reactive Dyes

- Acid Dyes

- Disperse Dyes

- Pigment Inks

By Application

- Apparel

- Home Textiles

- Fashion Textiles

- Industrial Textiles

By End-User

- Textile Manufacturers

- Fashion Designers

- Print Service Providers (PSPs)

- Retail Brands

By Machine Width

- Below By 8 Meters

- By 8 to 3 Meters

- Above 3 Meters

By Region

- North America

- U.S.

- Canada

- Europe

- U.K.

- France

- Germany

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia Pacific

- Latin America

- Brazil

- Rest of Latin America

- The Middle East and Africa

- GCC Countries

- South Africa

- Rest of Middle East Africa

Frequently Asked Questions

What will be the value of the Single-Pass Digital Textile Printing Machine market during 2024- 2032?

Table Of Content

Inquiry For Buying

Single-Pass Digital Textile Printing Machine

Request Sample

Single-Pass Digital Textile Printing Machine