Single Piece Drive Shaft Market Size, Share, and Trends Analysis Report

CAGR :

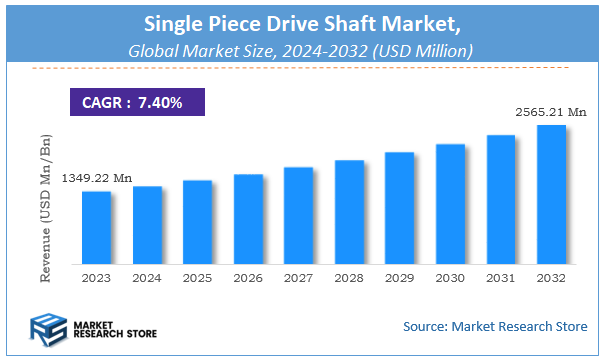

| Market Size 2023 (Base Year) | USD 1349.22 Million |

| Market Size 2032 (Forecast Year) | USD 2565.21 Million |

| CAGR | 7.4% |

| Forecast Period | 2024 - 2032 |

| Historical Period | 2018 - 2023 |

Single Piece Drive Shaft Market Insights

According to Market Research Store, the global single piece drive shaft market size was valued at around USD 1349.22 million in 2023 and is estimated to reach USD 2565.21 million by 2032, to register a CAGR of approximately 7.4% in terms of revenue during the forecast period 2024-2032.

The single piece drive shaft report provides a comprehensive analysis of the market, including its size, share, growth trends, revenue details, and other crucial information regarding the target market. It also covers the drivers, restraints, opportunities, and challenges till 2032.

To Get more Insights, Request a Free Sample

Global Single Piece Drive Shaft Market: Overview

The single piece drive shaft market refers to the industry involved in the design, manufacturing, and supply of one-piece drive shafts used to transmit torque and rotation in vehicles and industrial machinery. Unlike multi-piece drive shafts, single piece drive shafts are constructed from a single continuous tube, often made of materials such as steel, aluminum, or carbon fiber, offering advantages like reduced weight, fewer components, improved rotational balance, and higher strength. These drive shafts are widely used in performance vehicles, trucks, and off-road vehicles where durability, efficiency, and vibration reduction are critical. The market is closely linked to automotive production trends, technological innovations, and the demand for lightweight, high-performance driveline systems.

The market is driven by increasing demand for high-performance and fuel-efficient vehicles, particularly in the automotive and motorsports industries. The rising adoption of lightweight materials like aluminum and carbon fiber in driveline components is contributing to the growing preference for single piece drive shafts due to their ability to reduce vehicle weight and enhance fuel economy. Additionally, advancements in automotive engineering, such as higher powertrain outputs and improved vehicle dynamics, are supporting the need for stronger and more reliable drive shafts. Growth in off-road and utility vehicles, along with aftermarket customization trends, also fuels market expansion.

Key Highlights

- The single piece drive shaft market is anticipated to grow at a CAGR of 7.4% during the forecast period.

- The global single piece drive shaft market was estimated to be worth approximately USD 1349.22 million in 2023 and is projected to reach a value of USD 2565.21 million by 2032.

- The growth of the single piece drive shaft market is being driven by the automotive industry's strong push towards enhanced fuel efficiency and reduced emissions.

- Based on the product, the rigid shaft segment is growing at a high rate and is projected to dominate the market.

- On the basis of application, the light trucks segment is projected to swipe the largest market share.

- By region, North America is expected to dominate the global market during the forecast period.

Single Piece Drive Shaft Market: Dynamics

Key Growth Drivers

- Improved NVH (Noise, Vibration, and Harshness) Characteristics: Single piece drive shafts, particularly those made of advanced materials like carbon fiber or aluminum, can offer better NVH performance compared to multi-piece shafts with center supports, leading to a smoother and quieter ride.

- Reduced Weight: Single piece drive shafts, especially those made of lightweight materials, contribute to overall vehicle weight reduction, improving fuel efficiency and handling. This is a significant driver in the automotive industry due to stringent emission regulations.

- Simplified Design and Assembly: A single piece design eliminates the need for center supports, bearings, and associated hardware, simplifying assembly processes for vehicle manufacturers and potentially reducing manufacturing costs in the long run.

- Enhanced Durability (in specific applications): For certain applications and power transmission requirements, a well-designed single piece drive shaft can offer comparable or even better durability by eliminating potential failure points associated with intermediate supports.

- Increased Demand for High-Performance Vehicles: In performance-oriented vehicles, the benefits of reduced weight and improved NVH offered by single piece drive shafts are highly valued, driving their adoption.

- Adoption in Light Commercial Vehicles: The advantages of simplified design and reduced weight are also making single piece drive shafts increasingly attractive for light commercial vehicles.

Restraints

- Length Limitations: Manufacturing and transporting very long single piece drive shafts can be challenging and costly. This limits their applicability in vehicles with long wheelbases or specific driveline configurations.

- Critical Speed Issues: Longer single piece drive shafts are more susceptible to vibrations and reaching their critical speed at lower RPMs, potentially leading to instability and failure. This necessitates careful design and material selection.

- Higher Material Costs (for advanced materials): While simplifying assembly, single piece drive shafts made of advanced materials like carbon fiber or high-strength aluminum can have higher raw material costs compared to traditional steel multi-piece shafts.

- Design Constraints: Vehicle architecture and driveline layout may not always be conducive to accommodating a single piece drive shaft, requiring significant redesign.

- Limited Flexibility in Driveline Design: The fixed length of a single piece drive shaft offers less flexibility in driveline design compared to multi-piece shafts that can accommodate variations in chassis length and engine/transmission placement.

- Potential for Higher Stress Concentration: Improper design or manufacturing of a single piece drive shaft can lead to stress concentration points, potentially compromising its structural integrity.

Opportunities

- Advancements in Lightweight Materials: Ongoing developments in carbon fiber, aluminum alloys, and composite materials are improving the feasibility and cost-effectiveness of lightweight single piece drive shafts for a wider range of vehicles.

- Innovative Manufacturing Processes: New manufacturing techniques can help overcome length limitations and reduce production costs for single piece drive shafts.

- Growing Electric Vehicle (EV) Market (niche applications): While many EVs have different power transmission systems, some larger EVs or those with specific drive configurations might benefit from lightweight single piece drive shafts for connecting motors to axles.

- Aftermarket Demand for Performance Upgrades: The automotive aftermarket presents opportunities for single piece drive shafts as performance upgrades, offering weight reduction and improved NVH.

- Industrial Applications: Exploring the use of single piece drive shafts in specific industrial machinery where weight reduction, simplified design, and NVH are critical.

- Development of Damping Technologies: Integration of advanced damping technologies within single piece drive shafts can help mitigate critical speed issues and expand their applicability to longer lengths.

Challenges

- Balancing Cost and Performance: The primary challenge is to develop single piece drive shafts that offer significant performance advantages (weight, NVH) without a prohibitive cost increase compared to traditional multi-piece solutions.

- Overcoming Length and Critical Speed Limitations: Engineering solutions are needed to enable the use of longer single piece drive shafts without compromising stability and reliability.

- Ensuring Durability and Reliability: Maintaining high levels of durability and reliability under various operating conditions is crucial for widespread adoption.

- Meeting Stringent OEM Specifications: Automotive OEMs have rigorous specifications for driveline components, and single piece drive shafts must meet these demanding requirements.

- Scaling Up Production for Mass Market Adoption: Manufacturing high volumes of advanced material single piece drive shafts at competitive prices requires significant investment and efficient production processes.

- Developing Robust Testing and Validation Procedures: Ensuring the long-term performance and safety of single piece drive shafts requires comprehensive testing and validation protocols.

Single Piece Drive Shaft Market: Report Scope

This report thoroughly analyzes the Single Piece Drive Shaft Market, exploring its historical trends, current state, and future projections. The market estimates presented result from a robust research methodology, incorporating primary research, secondary sources, and expert opinions. These estimates are influenced by the prevailing market dynamics as well as key economic, social, and political factors. Furthermore, the report considers the impact of regulations, government expenditures, and advancements in research and development on the market. Both positive and negative shifts are evaluated to ensure a comprehensive and accurate market outlook.

| Report Attributes | Report Details |

|---|---|

| Report Name | Single Piece Drive Shaft Market |

| Market Size in 2023 | USD 1349.22 Million |

| Market Forecast in 2032 | USD 2565.21 Million |

| Growth Rate | CAGR of 7.4% |

| Number of Pages | 157 |

| Key Companies Covered | GKN, NTN, SDS, Dana, Nexteer, Hyundai-Wia, IFA Rotorion, Meritor, AAM, Neapco |

| Segments Covered | By Product, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2023 |

| Forecast Year | 2024 to 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Single Piece Drive Shaft Market: Segmentation Insights

The global single piece drive shaft market is divided by product, application, and region.

Segmentation Insights by Product

Based on product, the global single piece drive shaft market is divided into rigid shaft and hollow shaft.

Rigid Shaft currently dominates the Single Piece Drive Shaft Market, particularly due to its robust structure and widespread use across heavy-duty vehicles and industrial machinery. Its solid, non-hollow design offers high torsional rigidity and strength, making it the preferred choice in applications where durability, load capacity, and minimal maintenance are essential. The rigid shaft's proven reliability in commercial vehicles, construction equipment, and agricultural machinery ensures its leading market position, especially in regions with high demand for industrial transport and infrastructure development.

Hollow Shaft, while growing in popularity, remains a secondary segment but is experiencing faster growth due to rising adoption in passenger vehicles and electric mobility. Its lightweight design contributes to improved fuel efficiency and performance, aligning with current automotive trends. However, despite these advantages, hollow shafts are still emerging in comparison to the more established rigid shaft segment, which continues to hold the larger market share.

Segmentation Insights by Application

On the basis of application, the global single piece drive shaft market is bifurcated into light trucks and SUVs.

Light Trucks represent the dominant segment in the Single Piece Drive Shaft Market, driven by the increasing global demand for utility and commercial transport vehicles. Light trucks are extensively used in logistics, delivery services, and construction-related activities, especially in North America and parts of Asia-Pacific, where road infrastructure and economic activity support high fleet deployment. The robustness and load-bearing capability of single piece drive shafts align well with the performance requirements of light trucks, making this application segment a key revenue contributor for market players.

SUVs form a steadily growing segment, fueled by the rising popularity of sport utility vehicles for both urban and off-road driving. The shift toward fuel-efficient and high-performance drivetrains in SUVs supports the adoption of single piece drive shafts, especially in premium models. However, despite this growth, the overall market share of SUVs remains behind that of light trucks due to the latter’s broader commercial use and volume of production.

Single Piece Drive Shaft Market: Regional Insights

- North America is expected to dominate the global market.

North America dominates the Single Piece Drive Shaft Market due to the region’s robust automotive and aerospace industries. The United States is the key contributor, with major OEMs like Ford, GM, and Tesla incorporating single-piece carbon fiber and aluminum drive shafts to improve vehicle dynamics, reduce weight, and enhance fuel efficiency. The trend is particularly pronounced in performance cars and electric vehicles, where drivetrain efficiency is critical. The region also benefits from strong demand in off-road, agricultural, and commercial vehicles, especially in sectors requiring high torque and durability.

Europe holds a significant market share, driven by its well-established automotive manufacturing base and strict regulations regarding fuel efficiency and emissions. Germany leads in both innovation and adoption, supported by luxury carmakers like BMW, Audi, and Mercedes-Benz that integrate high-performance single-piece shafts to enhance vehicle handling and efficiency. The UK, France, and Italy also show strong uptake, especially in motorsport applications and lightweight commercial vehicle manufacturing. Europe's increasing investment in electric mobility is further accelerating the shift toward single-piece composite drive shafts.

Asia Pacific is the fastest-growing region in the Single Piece Drive Shaft Market, primarily led by China, Japan, South Korea, and India. China, as the world’s largest automotive producer, is rapidly adopting advanced drivetrain technologies to meet global standards and improve vehicle performance. Japanese automakers are incorporating lightweight shafts to meet their precision and efficiency standards, especially in hybrid and EV segments. South Korea, with its strong automotive exports and investments in carbon composite technologies, contributes significantly. India is seeing rising demand in commercial vehicles, driven by increased infrastructure activity and focus on vehicle efficiency.

Latin America shows moderate growth, with Brazil and Mexico being the leading markets. Brazil’s growing commercial vehicle and agriculture machinery sector supports the demand for strong, reliable single-piece drive shafts. Mexico’s position as a manufacturing hub for North American automotive OEMs also drives adoption, especially in export-oriented production facilities. However, limited local manufacturing of advanced materials may restrict widespread adoption in lower-cost vehicle segments.

The Middle East & Africa is witnessing emerging demand, particularly in the UAE, Saudi Arabia, and South Africa. The market here is supported by growing demand for durable drive shafts in utility vehicles, heavy equipment, and high-performance off-road applications. South Africa’s automotive manufacturing and export industry contributes modestly, while increased investment in transportation infrastructure and mining equipment across Africa is expected to gradually support market expansion.

Single Piece Drive Shaft Market: Competitive Landscape

The report provides an in-depth analysis of companies operating in the single piece drive shaft market, including their geographic presence, business strategies, product offerings, market share, and recent developments. This analysis helps to understand market competition.

Some of the major players in the global single piece drive shaft market include:

- GKN

- NTN

- SDS

- Dana

- Nexteer

- Hyundai-Wia

- IFA Rotorion

- Meritor

- AAM

- Neapco

The global single piece drive shaft market is segmented as follows:

By Product

- Rigid Shaft

- Hollow Shaft

By Application

- Light Trucks

- SUVs

By Region

- North America

- U.S.

- Canada

- Europe

- U.K.

- France

- Germany

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia Pacific

- Latin America

- Brazil

- Rest of Latin America

- The Middle East and Africa

- GCC Countries

- South Africa

- Rest of Middle East Africa

Frequently Asked Questions

Table Of Content

Inquiry For Buying

Single Piece Drive Shaft

Request Sample

Single Piece Drive Shaft