Synthetic Rubber And Fibers Market Size, Share, and Trends Analysis Report

CAGR :

| Market Size 2023 (Base Year) | USD 24.15 Billion |

| Market Size 2032 (Forecast Year) | USD 45.61 Billion |

| CAGR | 7.32% |

| Forecast Period | 2024 - 2032 |

| Historical Period | 2018 - 2023 |

Synthetic Rubber And Fibers Market Insights

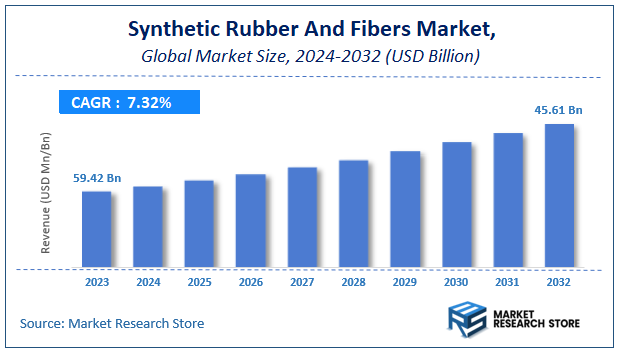

According to Market Research Store, the global synthetic rubber and fibers market size was valued at around USD 24.15 billion in 2023 and is estimated to reach USD 45.61 billion by 2032, to register a CAGR of approximately 7.32% in terms of revenue during the forecast period 2024-2032.

The synthetic rubber and fibers report provides a comprehensive analysis of the market, including its size, share, growth trends, revenue details, and other crucial information regarding the target market. It also covers the drivers, restraints, opportunities, and challenges till 2032.

To Get more Insights, Request a Free Sample

Global Synthetic Rubber and Fibers Market: Overview

The Synthetic Rubber and Fibers Market encompasses the production and distribution of man-made elastomers and fibers, which are integral to various industries due to their durability, versatility, and cost-effectiveness. Synthetic rubber, primarily derived from petrochemicals, is extensively used in automotive components, industrial goods, and consumer products. Synthetic fibers, such as polyester, nylon, and acrylic, are prevalent in textiles, home furnishings, and technical applications. The market's growth is propelled by factors like the expansion of the automotive and textile industries, increasing demand for durable and lightweight materials, and advancements in manufacturing technologies. However, environmental concerns and regulatory pressures are prompting a shift towards sustainable and bio-based alternatives.

Key drivers of the synthetic rubber and fibers market include the rising demand for automotive tires and components, driven by global vehicle production and the need for high-performance materials. In the synthetic fibers segment, growth is fueled by the increasing consumption of textiles and apparel, especially in emerging economies, and the demand for cost-effective, easy-to-maintain fabrics. Technological innovations, such as the development of bio-based and recycled materials, are also contributing to market expansion. Additionally, the growing emphasis on sustainability and environmental regulations is influencing manufacturers to adopt eco-friendly production processes and materials.

Key Highlights

- The synthetic rubber and fibers market is anticipated to grow at a CAGR of 7.32% during the forecast period.

- The global synthetic rubber and fibers market was estimated to be worth approximately USD 24.15 billion in 2023 and is projected to reach a value of USD 45.61 billion by 2032.

- The growth of the synthetic rubber and fibers market is being driven by the expanding automotive industry, particularly tire production and the increasing adoption of electric vehicles, which require specialized synthetic rubber compounds.

- Based on the type, the synthetic fibers segment is growing at a high rate and is projected to dominate the market.

- On the basis of application, the industrial segment is projected to swipe the largest market share.

- By region, North America is expected to dominate the global market during the forecast period.

Synthetic Rubber and Fibers Market: Dynamics

Key Growth Drivers

- Growing Demand from the Automotive Industry: synthetic rubber and fibers is a crucial component in tires, hoses, seals, and other automotive parts. The increasing global production and sales of vehicles, including electric vehicles, directly drive demand. Synthetic fibers are also used in car interiors and tire reinforcement.

- Expanding Textile and Apparel Industries: Synthetic fibers like polyester, nylon, and acrylic are widely used in clothing, home textiles, and industrial fabrics due to their versatility, durability, and cost-effectiveness, fueling market growth alongside the expanding textile sector.

- Increasing Applications in Construction: Synthetic rubber is used in sealants, adhesives, roofing membranes, and other construction materials due to its weather resistance and flexibility. Synthetic fibers reinforce concrete and other building materials.

- Rising Demand in Packaging: Synthetic polymers, including some synthetic rubbers and fibers in processed forms, are extensively used in packaging materials due to their barrier properties, strength, and cost-effectiveness, driven by the growing e-commerce and consumer goods sectors.

- Technological Advancements Leading to New Applications: Continuous innovation in polymer science is resulting in new types of synthetic rubbers and fibers with enhanced properties (e.g., high performance elastomers, specialty fibers), opening up new applications in aerospace, medical devices, and electronics.

- Cost-Effectiveness Compared to Natural Alternatives: In many applications, synthetic rubber and fibers offer a more cost-effective alternative to natural rubber and natural fibers while often providing superior or tailored performance characteristics.

- Consistent and Scalable Production: Synthetic materials can be produced with more consistent quality and in larger volumes compared to natural sources, ensuring a reliable supply for industrial needs.

- Growing Infrastructure Development: Investments in infrastructure projects globally, including roads, bridges, and buildings, increase the demand for synthetic rubber and fiber-based materials.

Restraints

- Volatility in Raw Material Prices (Crude Oil and Natural Gas Derivatives): The production of most synthetic rubbers and fibers relies heavily on petrochemical feedstocks. Fluctuations in crude oil and natural gas prices can significantly impact production costs and market prices.

- Environmental Concerns Regarding Production and Disposal: The production processes for some synthetic materials can be energy-intensive and generate waste. Concerns about the non-biodegradability of certain synthetic polymers and the accumulation of plastic waste can restrain market growth.

- Increasing Focus on Sustainability and Bio-Based Alternatives: Growing environmental awareness and consumer preference for sustainable products are driving research and development into bio-based rubbers and fibers, potentially substituting some synthetic materials.

- Stringent Regulations on VOC Emissions and Chemical Usage: Regulations aimed at reducing volatile organic compound (VOC) emissions and restricting the use of certain chemicals in manufacturing processes can increase production costs and limit the use of some synthetic materials.

- Performance Limitations in Specific Applications: While versatile, some synthetic rubbers and fibers may not match the specific performance characteristics of natural alternatives in certain niche applications (e.g., the unique elasticity of natural rubber in some high-performance tires).

- Economic Downturns and Reduced Industrial Activity: Economic recessions can lead to decreased demand from key end-use industries like automotive and construction, impacting the market for synthetic rubber and fibers.

- Competition from Recycled Materials: The increasing focus on circular economy principles and advancements in recycling technologies are leading to greater use of recycled polymers, potentially reducing the demand for virgin synthetic materials.

- Trade Barriers and Geopolitical Instability: Trade disputes and geopolitical tensions can disrupt supply chains and impact the international trade of synthetic rubber and fibers.

Opportunities

- Development of Bio-Based and Sustainable Synthetic Materials: Innovations in bio-based feedstocks and production processes for synthetic rubber and fibers can address environmental concerns and create new market segments.

- Creation of High-Performance and Specialty Polymers: Continued research into polymers with enhanced properties (e.g., extreme temperature resistance, high strength, self-healing capabilities) can open up new high-value applications.

- Advancements in Recycling Technologies for Synthetic Polymers: Developing more efficient and cost-effective methods for recycling synthetic rubber and fibers can promote a circular economy and reduce reliance on virgin materials.

- Growing Demand from Electric Vehicle (EV) Sector: EVs have specific requirements for tires (low rolling resistance), seals, and lightweighting materials, creating opportunities for tailored synthetic rubber and fiber solutions.

- Increasing Use in Medical Devices and Healthcare: Synthetic polymers with biocompatible and sterilizable properties are finding growing applications in medical devices, prosthetics, and drug delivery systems.

- Smart Textiles and Wearable Technology: The integration of synthetic fibers with electronic components is driving the development of smart textiles and wearable technology with applications in healthcare, sports, and fashion.

- Customization and Additive Manufacturing (3D Printing): Synthetic rubbers and fibers can be tailored for specific applications using advanced manufacturing techniques like 3D printing, creating opportunities for customized products.

- Expansion in Emerging Economies: Rapid industrialization and urbanization in developing countries are expected to significantly increase the demand for synthetic rubber and fiber-based products.

Challenges

- Balancing Cost Competitiveness with Sustainability: Developing sustainable synthetic materials that can compete on price with traditional petrochemical-based polymers is a significant challenge.

- Improving the End-of-Life Management of Synthetic Polymers: Finding effective and scalable solutions for the recycling and disposal of synthetic rubber and fiber waste to minimize environmental impact.

- Meeting Increasingly Stringent Environmental Regulations: Continuously adapting production processes and developing new materials to comply with evolving environmental regulations.

- Maintaining Performance While Incorporating Recycled or Bio-Based Content: Ensuring that synthetic materials with recycled or bio-based components meet the required performance standards for various applications.

- Addressing Consumer Perceptions Regarding Synthetic Materials: Overcoming negative consumer perceptions associated with the environmental impact of synthetic polymers through education and the development of more sustainable options.

- Ensuring Supply Chain Resilience and Diversification: Mitigating the risks associated with volatile raw material prices and geopolitical instability by diversifying supply chains.

- Developing New Polymers with Breakthrough Properties: Continuing to invest in research and development to create novel synthetic rubbers and fibers with significantly enhanced performance characteristics.

- Adapting to the Evolving Demands of End-Use Industries: Staying abreast of and responding to the changing needs and technological advancements in key sectors like automotive, textiles, and construction.

Synthetic Rubber And Fibers Market: Report Scope

This report thoroughly analyzes the Synthetic Rubber And Fibers Market, exploring its historical trends, current state, and future projections. The market estimates presented result from a robust research methodology, incorporating primary research, secondary sources, and expert opinions. These estimates are influenced by the prevailing market dynamics as well as key economic, social, and political factors. Furthermore, the report considers the impact of regulations, government expenditures, and advancements in research and development on the market. Both positive and negative shifts are evaluated to ensure a comprehensive and accurate market outlook.

| Report Attributes | Report Details |

|---|---|

| Report Name | Synthetic Rubber And Fibers Market |

| Market Size in 2023 | USD 24.15 Billion |

| Market Forecast in 2032 | USD 45.61 Billion |

| Growth Rate | CAGR of 7.32% |

| Number of Pages | 157 |

| Key Companies Covered | Asahi Kasei Corporation, The Dow Chemical Company, DuPont, LANXESS AG, Exxon Mobil Corporation, Dynasol Elastomers S.A., TSRC Corporation, Versalis S.p.A., Sumitomo Chemical Co., Ltd., KUMHO PETROCHEMICAL, China National Petroleum Corporation (CNPC), Chin |

| Segments Covered | By Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2023 |

| Forecast Year | 2024 to 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Synthetic Rubber and Fibers Market: Segmentation Insights

The global synthetic rubber and fibers market is divided by type, application, and region.

Segmentation Insights by Type

Based on type, the global synthetic rubber and fibers market is divided into synthetic fibers, styrene butadiene rubber (SBR), polybutadiene (BR), and ethylene propylene (EPDM).

Synthetic Fibers are the dominant segment in the synthetic rubber and fibers market, capturing the largest market share due to their widespread use in apparel, home furnishings, industrial fabrics, and automotive interiors. Synthetic fibers like polyester, nylon, and acrylic are highly durable, wrinkle-resistant, and quick-drying, making them ideal for performance wear, upholstery, and commercial applications. Rapid growth in the fashion and textile industries, especially in emerging markets, continues to fuel demand. Furthermore, innovations in sustainable and recycled synthetic fibers are bolstering the segment's growth.

Styrene Butadiene Rubber (SBR) is a key component in tire manufacturing, accounting for a substantial share of synthetic rubber consumption. It offers excellent abrasion resistance, good aging stability, and cost-efficiency. Apart from automotive tires, SBR is used in footwear soles, conveyor belts, and industrial goods. The global expansion of the automotive industry, coupled with increased aftermarket tire replacements, drives the consistent growth of this segment.

Polybutadiene Rubber (BR) is known for its high resilience, low-temperature flexibility, and resistance to wear. It is often used in combination with SBR to improve tire performance and durability. BR is also applied in golf balls, footwear, and plastic modification. Its strong grip and reduced rolling resistance are critical in energy-efficient tire solutions, contributing to rising adoption in green mobility initiatives.

Ethylene Propylene Diene Monomer (EPDM) rubber is highly valued for its excellent resistance to heat, ozone, and weathering. It is widely used in automotive weather stripping, seals, roofing membranes, and hoses. Its ability to perform under harsh environmental conditions makes it an essential material in industrial and construction sectors. Despite occupying a smaller portion of the market compared to SBR and synthetic fibers, EPDM’s role in high-performance applications ensures steady demand.

Segmentation Insights by Application

On the basis of application, the global synthetic rubber and fibers market is bifurcated into industrial, manufacture, and others.

Industrial applications represent the dominant segment in the synthetic rubber and fibers market. This includes use in automotive tires, belts, hoses, gaskets, industrial rolls, vibration dampeners, and more. The sector benefits from the widespread need for durable, heat-resistant, and chemically stable materials in demanding mechanical and infrastructural environments. Additionally, industrial growth in emerging economies, coupled with rapid urbanization and infrastructure projects, continues to bolster demand for synthetic rubber-based solutions and high-performance synthetic fibers.

Manufacture applications encompass a broad range of end products, including sports goods, footwear, adhesives, and electrical insulation materials. Synthetic rubber is a preferred choice in these applications due to its moldability, shock resistance, and cost-effectiveness. Synthetic fibers, on the other hand, play a crucial role in manufacturing textiles, nonwoven fabrics, packaging, and construction materials. Innovations in lightweight, durable, and flame-retardant fiber materials are enhancing this segment’s relevance across varied manufacturing domains.

Synthetic Rubber and Fibers Market: Regional Insights

- North America is expected to dominate the global market.

North America dominates the global synthetic rubber and fibers market, driven by strong demand from its automotive, healthcare, and consumer goods industries. The United States plays a leading role in the region, with well-established manufacturing infrastructure supporting the production of synthetic rubber for use in tires, seals, hoses, and medical equipment. The healthcare sector also fuels demand through extensive usage in gloves, tubing, and protective wear. In the synthetic fibers segment, North America benefits from consumer preferences for low-maintenance, durable, and performance-enhancing textiles used in activewear, upholstery, and industrial fabrics. Moreover, growing environmental awareness is encouraging the development of recyclable and bio-based fiber alternatives across the region.

Asia-Pacific is a significant region in the synthetic rubber and fibers market, driven by its immense manufacturing scale, cost-efficiency, and expanding end-user industries. Countries such as China, India, Japan, and South Korea are at the forefront of production and consumption. China, in particular, leads in tire manufacturing and industrial applications, making it a global hub for synthetic rubber. The region also excels in synthetic fiber production, with high demand from apparel, home textiles, and industrial sectors. A large and growing population, rising disposable incomes, and increasing demand for affordable, functional textiles further propel market growth. Supportive government initiatives and continuous investment in production technology strengthen Asia-Pacific’s leadership in the market.

Europe holds a substantial share of the synthetic rubber and fibers market, characterized by high-quality manufacturing practices and a strong focus on sustainability. The region’s automotive sector is a major consumer of synthetic rubber for advanced components, while industrial and construction applications further boost demand. In the fibers segment, Europe is known for adopting environmentally friendly practices and promoting the use of recyclable and sustainable materials. Countries like Germany, Italy, and France are leaders in technical textiles and high-performance fabrics. Although growth is moderate compared to Asia-Pacific, Europe's regulatory influence and commitment to green innovation shape global industry standards.

Latin America is an emerging market for synthetic rubber and fibers, with growth supported by increasing automotive production, urbanization, and textile industry expansion. Brazil and Mexico are the principal contributors, where synthetic rubber is widely used in vehicle components and construction materials. The region’s synthetic fiber consumption is growing steadily due to higher demand for affordable clothing and home textiles. Although the industry is still developing, improved access to materials, greater regional trade, and a rising middle class are laying the groundwork for sustained market advancement in the coming years.

Middle East & Africa region is gradually building momentum in the synthetic rubber and fibers market, propelled by infrastructure growth, industrialization, and diversification of regional economies. The construction and oil & gas sectors contribute significantly to the demand for synthetic rubber, especially in protective and structural applications. In synthetic fibers, the market is expanding in response to increased manufacturing capacity and demand for practical, moisture-resistant fabrics in hot climates. While the market share remains smaller compared to other regions, future growth is expected as the region continues to invest in industrial and textile capabilities.

Synthetic Rubber and Fibers Market: Competitive Landscape

The report provides an in-depth analysis of companies operating in the synthetic rubber and fibers market, including their geographic presence, business strategies, product offerings, market share, and recent developments. This analysis helps to understand market competition.

Some of the major players in the global synthetic rubber and fibers market include:

- Asahi Kasei Corporation

- The Dow Chemical Company

- DuPont

- LANXESS AG

- Exxon Mobil Corporation

- Dynasol Elastomers S.A.

- TSRC Corporation

- Versalis S.p.A.

- Sumitomo Chemical Co. Ltd.

- KUMHO PETROCHEMICAL

- China National Petroleum Corporation (CNPC)

- China Petroleum & Chemical Corporation (Sinopec Corporation)

The global synthetic rubber and fibers market is segmented as follows:

By Type

- Synthetic Fibers

- Styrene Butadiene Rubber(SBR)

- Polybutadiene(BR)

- Ethylene Propylene(EPDM)

By Application

- Industrial

- Manufacture

- Others

By Region

- North America

- U.S.

- Canada

- Europe

- U.K.

- France

- Germany

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia Pacific

- Latin America

- Brazil

- Rest of Latin America

- The Middle East and Africa

- GCC Countries

- South Africa

- Rest of Middle East Africa

Frequently Asked Questions

Table Of Content

Inquiry For Buying

Synthetic Rubber And Fibers

Request Sample

Synthetic Rubber And Fibers