01-Jul-2025 | Market Research Store

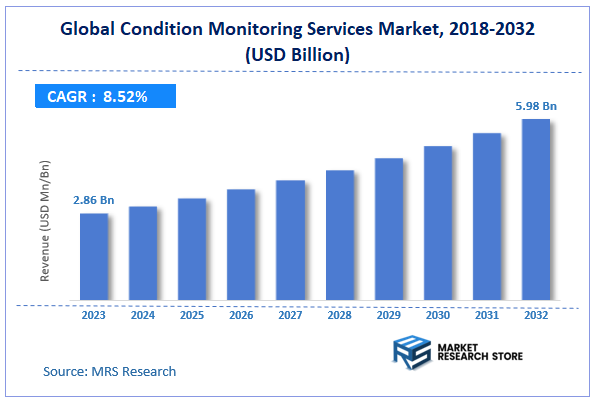

Market Research Store has published a new report on the global condition monitoring services market, highlighting strong growth driven by increasing demand for predictive maintenance and industrial asset management. The condition monitoring services market was valued at USD 2.86 billion in 2023 and is projected to reach USD 5.98 billion by 2032, growing at a CAGR of 8.52% during the forecast period 2024–2032. The report covers key market drivers, technological innovations, industry trends, challenges, and future opportunities shaping the condition monitoring services landscape.

This pivotal report is designed to serve as an indispensable resource for asset-intensive industries, maintenance and reliability professionals, technology providers, and investors seeking to understand and capitalize on the burgeoning shift from reactive to proactive maintenance strategies. Condition monitoring services are at the forefront of this transformation, enabling industries to predict equipment failures, optimize operational efficiency, enhance safety, and significantly reduce downtime and maintenance costs. This report provides a detailed, step-by-step understanding of the market's dynamics and its promising future trajectory.

For more information about this report visit: https://www.marketresearchstore.com/market-insights/condition-monitoring-services-market-828773

Market Definition

The Global Condition Monitoring Services Market encompasses a range of specialized services focused on assessing the health and performance of industrial machinery and critical assets in real-time or near real-time. These services involve the continuous or periodic collection and analysis of data from equipment, such as vibration, temperature, oil quality, acoustic emissions, and motor current signatures. The primary objective is to detect early signs of degradation or potential failure, allowing for timely intervention, scheduled maintenance, and prevention of costly unplanned downtime. Condition monitoring services are integral to predictive maintenance programs, helping industries optimize asset utilization, extend equipment lifespan, improve safety, and enhance overall operational efficiency across various sectors.

Key Highlights

This comprehensive research report offers a multi-faceted analysis of the Global Condition Monitoring Services Market, providing critical insights into its key aspects. Some of the prominent highlights include:

Market Size and Growth: The report meticulously tracks the historical market size from 2018 to 2022, establishing a robust baseline for future projections. The analysis indicates a strong growth trajectory, with the market poised for significant expansion from USD 2.86 Billion in 2023 to USD 5.98 Billion by 2032, registering an impressive CAGR of 8.52% during the forecast period (2024-2032). This robust growth is primarily fueled by the increasing adoption of Industry 4.0 initiatives, the growing recognition of the significant cost savings and operational benefits offered by predictive maintenance, the rising complexity of industrial machinery, and the imperative for industries to minimize unplanned downtime and enhance safety.

Consumer Preferences: The report identifies key preferences among industrial clients and asset owners for condition monitoring services. Customers prioritize accuracy and reliability of data and insights, enabling confident decision-making. There is a strong demand for actionable intelligence rather than just raw data, with clear recommendations for maintenance actions. Real-time monitoring capabilities and remote accessibility are highly valued, allowing for continuous oversight and rapid response. Furthermore, clients seek cost-effectiveness and a clear Return on Investment (ROI), along with solutions that are easy to integrate with existing enterprise asset management (EAM) or computerized maintenance management systems (CMMS). Comprehensive solutions covering multiple monitoring techniques and asset types are also preferred.

Technological Innovations: The report highlights cutting-edge technological innovations that are the bedrock of the condition monitoring services market. These include the proliferation of advanced IoT sensors that are smaller, more robust, and wirelessly connected, enabling pervasive data collection. The integration of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is transforming data analysis, allowing for automated anomaly detection, predictive modeling, and even prescriptive recommendations. Cloud computing platforms provide scalable infrastructure for data storage and processing. Innovations in wireless communication technologies (e.g., 5G, LoRaWAN) facilitate remote monitoring in challenging environments. Furthermore, the development of digital twin technology is enhancing predictive capabilities by creating virtual replicas of physical assets for simulation and analysis.

Market Segmentation: The report provides a detailed segmentation of the Global Condition Monitoring Services Market, offering a granular understanding of its diverse components:

- By Technique: This segment includes various monitoring methods such as Vibration Analysis, Thermography (Infrared Thermography), Oil Analysis, Acoustic Emission Testing, Motor Current Signature Analysis (MCSA), Ultrasonic Testing, and Corrosion Monitoring. Vibration Analysis is a dominating technique due to its effectiveness in detecting mechanical faults in rotating machinery.

- By Application: This covers the diverse industrial sectors utilizing these services, including Oil & Gas, Power Generation (e.g., thermal, nuclear, wind), Manufacturing, Metals & Mining, Automotive, Aerospace & Defense, Chemical & Petrochemical, and Pulp & Paper. The Power Generation and Oil & Gas sectors are significant application areas due to their asset-intensive nature and high costs associated with downtime.

Dominating Region in Segmentation: The Application segment, particularly Power Generation and Oil & Gas, consistently drives significant demand. Within the Technique segment, Vibration Analysis remains a widely adopted and dominating method.

Regional Analysis: The report provides an in-depth regional analysis, covering North America, Europe, Asia Pacific (APAC), Latin America, the Middle East, and Africa (MEA). Each region is meticulously analyzed based on market size, industrial development, regulatory frameworks, and technological adoption rates. North America is identified as the dominating region in the Global Condition Monitoring Services Market. This leadership is attributed to its well-established industrial infrastructure, early adoption of advanced maintenance technologies, significant investments in digitalization and Industry 4.0, and the presence of numerous key market players and service providers. Europe also holds a substantial market share, driven by stringent safety regulations and a focus on operational efficiency. Asia Pacific (APAC) is projected to exhibit the highest growth rates, fueled by rapid industrialization, increasing manufacturing activities, and growing awareness of predictive maintenance benefits in emerging economies like China and India.

Competitive Landscape: The report features an in-depth analysis of the competitive landscape, profiling key players operating in the Global Condition Monitoring Services Market. These prominent companies include: AMETEK, Anfatec Instruments, FEMTO-St, NF, Stanford Research Systems, Zurich Instruments, and others. The competitive landscape is diverse, comprising specialized condition monitoring firms, large industrial conglomerates offering integrated solutions, and technology providers developing advanced sensing and analytics platforms. Companies are focusing on expanding their service portfolios, investing in AI/ML capabilities, developing industry-specific solutions, and forging strategic partnerships to enhance their market presence and offer comprehensive asset health management solutions.

Sustainability Trends: Condition monitoring services significantly contribute to broader sustainability goals in industrial operations. By enabling predictive maintenance, these services help extend the operational life of machinery, reducing the need for premature replacements and conserving resources. They promote energy efficiency by ensuring equipment operates at optimal performance, minimizing wasted energy due to inefficiencies or impending failures. Furthermore, by preventing catastrophic breakdowns, they help reduce the generation of industrial waste (e.g., damaged parts, lubricants from spills) and mitigate potential environmental hazards. The optimization of maintenance schedules also leads to more efficient use of labor and resources, aligning with principles of sustainable industrial practices.

Challenges & Opportunities

While the Global Condition Monitoring Services Market demonstrates robust growth, it also faces specific challenges that require strategic navigation. Concurrently, numerous opportunities are emerging that can be leveraged for future expansion.

Challenges

- High Initial Investment: The upfront cost of implementing comprehensive condition monitoring systems, including sensors, software, and integration with existing systems, can be a significant barrier for some organizations, particularly SMEs.

- Data Overload and Interpretation: The sheer volume and complexity of data generated by condition monitoring sensors can be overwhelming, requiring sophisticated analytics tools and skilled personnel for accurate interpretation and actionable insights.

- Integration with Legacy Systems: Integrating new condition monitoring solutions with older, disparate legacy industrial control and IT systems can be technically challenging and time-consuming.

- Shortage of Skilled Personnel: There is a growing demand for professionals with expertise in vibration analysis, thermography, data science, and industrial IoT, leading to a shortage of qualified personnel.

- Cybersecurity Concerns: As more industrial assets become connected, ensuring the cybersecurity of condition monitoring data and systems is paramount to prevent unauthorized access or malicious attacks.

Opportunities

- Accelerated Industry 4.0 Adoption: The global push towards smart factories, digital twins, and connected enterprises is a major catalyst for the adoption of condition monitoring services as a core component of industrial digitalization.

- Shift from Reactive to Predictive Maintenance: Industries are increasingly recognizing the substantial cost savings, reduced downtime, and improved safety associated with predictive maintenance, driving the demand for condition monitoring.

- Cost Savings and ROI Demonstration: The clear and quantifiable return on investment (ROI) from preventing costly unplanned outages and optimizing maintenance schedules is a powerful incentive for adoption.

- Remote Monitoring and Diagnostics: Advancements in connectivity and cloud platforms enable remote monitoring and expert diagnostics, particularly beneficial for geographically dispersed assets or hazardous environments.

- Expansion into New Industries: Beyond traditional heavy industries, condition monitoring is gaining traction in sectors like smart buildings, healthcare (for critical equipment), and transportation, opening new market avenues.

- AI and Machine Learning Advancements: Continuous improvements in AI and ML algorithms are enhancing the accuracy, predictive power, and automation of condition monitoring analysis, leading to more precise and timely interventions.

Future Outlook

The Global Condition Monitoring Services Market is poised for a transformative future, becoming an indispensable pillar of modern industrial operations. The future outlook points towards highly integrated, AI-driven, and autonomous condition monitoring systems that provide not just predictive but also prescriptive maintenance recommendations. We anticipate a deeper convergence with digital twin technology, enabling real-time simulation and optimization of asset performance. The market will see a greater emphasis on end-to-end asset performance management (APM) solutions that combine condition monitoring with other operational data for holistic insights. Ultimately, condition monitoring services will evolve to deliver unparalleled levels of asset reliability, operational efficiency, and sustainability, driving the next wave of industrial productivity and resilience globally.

About Us

Market Research Store is a single destination for all types of industries, global, and regional reports. We feature large repository of latest industry reports and market statistics published by reputed private publishers and public organizations. Market Research Store is the comprehensive collection of market intelligence products and services available. Our vast database of reports enables our clients to benefit from expert insights on global industries, products, and market trends.

Contact Us

Market Research Store

244 Fifth Avenue, Suite N202

New York, 10001, United States

Tel: +1-302-444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

Email: sales@marketresearchstore.com

Website: www.marketresearchstore.com