15-Jul-2025 | Market Research Store

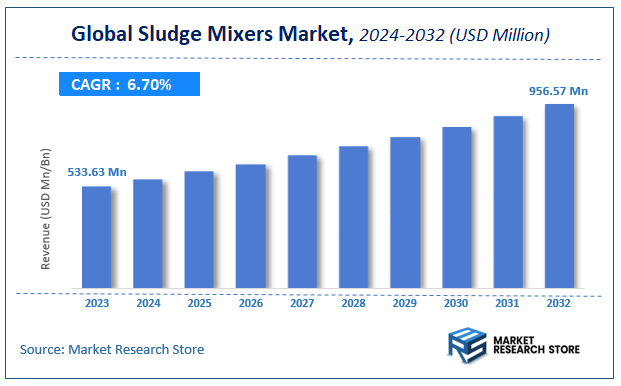

Market Research Store, a leading global provider of comprehensive market intelligence and consulting services, today announced the publication of its latest in-depth research report, titled "Sludge Mixers Market." This meticulously researched report offers an exhaustive analysis of the current market dynamics, key growth drivers, cutting-edge technological innovations, evolving operational demands, challenges, opportunities, and the strategic future outlook within the global sludge mixers industry. The report forecasts a substantial expansion of the sludge mixers market, from USD 533.63 Million in 2023 to a remarkable USD 956.57 Million by 2032, demonstrating a Compound Annual Growth Rate (CAGR) of 6.7% during the forecast period (2024-2032).

This pivotal report is designed to serve as an indispensable resource for wastewater treatment plant operators, industrial facilities, equipment manufacturers, engineering consultants, and investors seeking to understand and capitalize on the critical role of efficient sludge management in environmental protection and resource recovery. Sludge mixers are fundamental components in wastewater treatment processes, ensuring homogeneous mixing of solids and liquids, preventing settling, promoting biological reactions, and optimizing subsequent dewatering and disposal stages. Their importance is growing rapidly amidst increasing urbanization, stringent environmental regulations, and a heightened global focus on sustainable wastewater management. This report provides a detailed, step-by-step understanding of the market's dynamics and its promising future trajectory.

Access the Executive Summary of the Research Report: https://www.marketresearchstore.com/market-insights/sludge-mixers-market-829184

Market Definition

The global sludge mixers market encompasses the manufacturing, distribution, and application of specialized mechanical equipment designed to agitate, homogenize, and prevent the settling of sludge (a semi-solid byproduct of wastewater treatment) within various tanks and basins. These mixers are crucial for maintaining optimal conditions in different stages of sludge processing, including equalization, anaerobic and aerobic digestion, thickening, and storage. By ensuring uniform distribution of solids, nutrients, and microorganisms, sludge mixers enhance biological treatment efficiency, improve gas production in anaerobic digesters (for biogas recovery), prevent odor issues, and prepare sludge for more effective dewatering, ultimately reducing disposal volumes and costs. The market includes a range of mixing technologies and designs tailored to specific sludge characteristics and tank configurations, playing a vital role in the overall efficiency and environmental compliance of wastewater treatment plants and industrial facilities.

Key Highlights

This comprehensive research report offers a multi-faceted analysis of the global sludge mixers market, providing critical insights into its key aspects. Some of the prominent highlights include:

Market Size and Growth: The report meticulously tracks the historical market size from 2018 to 2023, establishing a robust baseline for future projections. The analysis indicates a consistent growth trajectory, with the market poised for significant expansion from USD 533.63 Million in 2023 to USD 956.57 Million by 2032, registering a steady CAGR of 6.7% during the forecast period (2024-2032). This robust growth is primarily fueled by increasing global urbanization and industrialization leading to higher volumes of wastewater, increasingly stringent environmental regulations on wastewater discharge and sludge disposal, and a growing emphasis on resource recovery (e.g., biogas from anaerobic digestion) from wastewater treatment processes.

Consumer Preferences: The report identifies key preferences among wastewater treatment plant operators and industrial end-users for sludge mixers. Energy efficiency is paramount, as mixing operations can be energy-intensive, driving demand for optimized designs and variable speed drives. Reliability and durability are crucial for continuous operation in harsh, corrosive environments, minimizing downtime and maintenance costs. Users prioritize effective mixing performance to ensure process stability and optimal treatment outcomes. Furthermore, there's a strong preference for ease of installation and maintenance, along with features like remote monitoring, automation capabilities, and compliance with relevant industry standards for safety and environmental performance.

Technological Innovations: The report highlights cutting-edge technological innovations shaping the sludge mixers market. These include advancements in impeller and propeller designs (e.g., high-efficiency impellers, self-cleaning designs) that optimize mixing patterns while reducing energy consumption. The integration of variable frequency drives (VFDs) allows for precise control of mixing intensity, adapting to varying sludge characteristics and energy demands. Innovations in materials of construction (e.g., corrosion-resistant alloys, specialized coatings) enhance durability and extend equipment lifespan. The development of smart mixing systems incorporating sensors for real-time monitoring of sludge properties (e.g., viscosity, solids content) and predictive analytics for maintenance is an emerging trend. Furthermore, advancements in computational fluid dynamics (CFD) are enabling more precise modeling and optimization of mixer performance.

Market Segmentation: The report provides a detailed segmentation of the global sludge mixers market, offering a granular understanding of its diverse components:

- By Type: This segment typically includes Submersible Mixers (most common, installed directly in the tank), Vertical Shaft Mixers (top-entry, often used in larger tanks), and Horizontal Mixers (for specific tank geometries or channels). Submersible Mixers are expected to dominate due to their versatility and ease of installation.

- By Application: This covers the primary stages of sludge treatment where mixers are used, such as Anaerobic Digesters, Aeration Basins, Equalization Tanks, Sludge Thickening, and Sludge Storage Tanks. Anaerobic Digesters represent a significant application due to the critical need for homogeneous mixing for biogas production.

- By End-User: This segment categorizes the primary consumers of sludge mixers, including Municipal Wastewater Treatment Plants, Industrial Wastewater Treatment Plants (e.g., Food & Beverage, Chemical, Pulp & Paper), and Others (e.g., Agriculture). Municipal Wastewater Treatment Plants are the largest end-user segment globally.

- By Mixing Technology: This includes Mechanical Mixers (e.g., propeller, impeller-based), Jet Mixers, and Gas Mixers (e.g., diffused air, bubble guns). Mechanical Mixers are widely adopted due to their proven effectiveness.

- By Compliance Standards: This segment considers adherence to regional or international regulations (e.g., ISO, local environmental agencies).

- Dominating Region in Segmentation: The End-User segment, particularly Municipal Wastewater Treatment Plants, consistently drives the highest demand. Geographically, Asia Pacific (APAC) is expected to dominate across most segments due to rapid infrastructure development.

Regional Analysis: The report provides an in-depth regional analysis, covering North America, Europe, Asia Pacific (APAC), Latin America, the Middle East, and Africa (MEA). Each region is meticulously analyzed based on market size, wastewater generation volumes, investment in treatment infrastructure, and environmental regulatory landscapes.

Asia Pacific (APAC) is identified as the dominating region in the global sludge mixers market. This leadership is attributed to rapid urbanization, increasing industrialization, significant investments in new wastewater treatment plant construction and upgrades, and the implementation of stricter environmental protection policies in countries like China and India. North America and Europe also hold substantial market shares, driven by aging infrastructure upgrades, a strong focus on energy efficiency, and advanced sludge management practices.

Competitive Landscape: The report features an in-depth analysis of the competitive landscape, profiling key players operating in the global sludge mixers market. These prominent companies include: WesTech, Sodimate, Ovivo, Flowserve SIHI, SALTEC, Pulsair Systems, and Design Controls. The competitive landscape is characterized by a mix of global water technology companies offering comprehensive solutions and specialized manufacturers focused on mixing equipment. Companies are focusing on continuous innovation in energy-efficient designs, enhancing product durability for demanding applications, expanding their global presence, and providing integrated solutions that align with smart water management initiatives.

Sustainability Trends: The Sludge Mixers market aligns strongly with global sustainability trends in wastewater management and resource recovery. By ensuring efficient mixing in anaerobic digesters, these mixers directly contribute to increased biogas production, which can be used as a renewable energy source, thereby reducing reliance on fossil fuels and lowering greenhouse gas emissions. Improved mixing also leads to better dewatering efficiency, reducing the volume of sludge for disposal and minimizing transportation costs and landfill burden. Furthermore, the development of energy-efficient mixer designs reduces the overall energy consumption of wastewater treatment plants, contributing to a lower operational carbon footprint and promoting a more circular approach to water and waste management.

Challenges & Opportunities

While the global sludge mixers market demonstrates robust growth, it also faces specific challenges that require strategic navigation. Concurrently, numerous opportunities are emerging that can be leveraged for future expansion.

Challenges

- High Initial Investment: The capital expenditure required for installing robust sludge mixing systems can be substantial, particularly for large-scale municipal or industrial plants.

- Corrosive Environment: Sludge environments are highly corrosive and abrasive, posing challenges for material selection and requiring durable designs to ensure long equipment lifespan and minimize maintenance.

- Operational Complexity: Optimizing mixing intensity for varying sludge characteristics and process stages can be complex, requiring skilled operators and advanced control systems.

- Energy Consumption: Despite efficiency improvements, mixing remains an energy-intensive process, and rising energy costs can impact operational budgets.

- Maintenance in Harsh Conditions: Performing maintenance on mixers submerged in sludge can be challenging and requires specialized procedures and safety protocols.

Opportunities

- Increasing Wastewater Treatment Infrastructure: The global imperative to expand and upgrade wastewater treatment capacities, especially in rapidly urbanizing regions, drives a direct demand for sludge mixers.

- Stricter Environmental Regulations: Growing regulatory pressure on wastewater discharge quality and sludge disposal methods mandates more efficient and advanced sludge management processes, boosting mixer adoption.

- Focus on Resource Recovery (Biogas): The increasing emphasis on recovering valuable resources from wastewater, particularly biogas from anaerobic digestion, directly fuels the demand for efficient digester mixers.

- Industrial Wastewater Treatment: The growth of various industries (e.g., food & beverage, chemical) generates significant volumes of industrial wastewater, creating a specialized market for robust sludge mixing solutions.

- Advancements in Smart Water Management: The integration of IoT, sensors, and automation in wastewater treatment plants creates opportunities for smart, self-optimizing sludge mixing systems.

- Demand for Energy-Efficient Solutions: The continuous drive to reduce operational costs and carbon footprints encourages the adoption of highly energy-efficient mixer designs.

- Aging Infrastructure Upgrade: In developed regions, the need to replace and upgrade aging wastewater treatment infrastructure presents a significant market opportunity for modern, efficient sludge mixers.

Future Outlook

The global sludge mixers market is poised for a dynamic future, becoming an increasingly intelligent and integral component of sustainable wastewater management. The future outlook points towards smarter, highly automated mixing systems that leverage real-time data and predictive analytics to optimize performance, reduce energy consumption, and minimize operational interventions. We anticipate further advancements in materials science and modular designs to enhance durability and ease of maintenance in challenging environments. The market will see a sustained focus on integrating mixers into comprehensive resource recovery solutions, particularly for biogas generation and nutrient recycling. Ultimately, sludge mixers will evolve to play an even more critical role in transforming wastewater treatment plants into resource recovery factories, contributing significantly to environmental protection and circular economy initiatives worldwide.

About Us

Market Research Store is a single destination for all types of industries, global, and regional reports. We feature large repository of latest industry reports and market statistics published by reputed private publishers and public organizations. Market Research Store is the comprehensive collection of market intelligence products and services available. Our vast database of reports enables our clients to benefit from expert insights on global industries, products, and market trends.

Contact Us

Market Research Store

244 Fifth Avenue, Suite N202

New York, 10001, United States

Tel: +1-302-444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

Email: sales@marketresearchstore.com

Website: www.marketresearchstore.com