15-Jul-2025 | Market Research Store

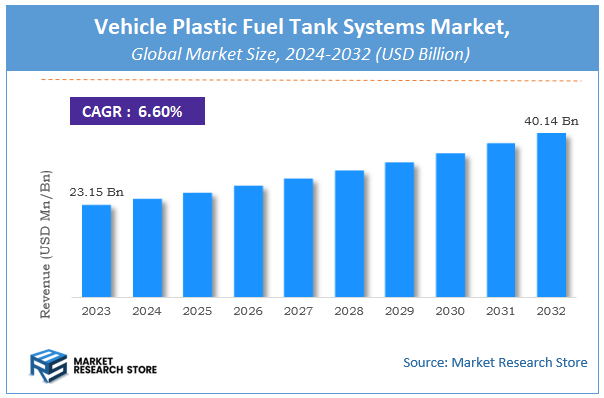

Market Research Store has published a new report on the global "Vehicle Plastic Fuel Tank Systems Market," which reveals robust growth prospects for this crucial automotive component sector. The vehicle plastic fuel tank systems market is projected to witness an impressive increase from USD 23.15 billion in 2023 to an estimated USD 40.14 billion by 2032. This significant expansion is anticipated at a Compound Annual Growth Rate (CAGR) of 6.6% over the forecast period from 2024 to 2032. This comprehensive market research report offers an in-depth analysis of market dynamics, key trends, competitive landscape, and future opportunities within this critical sector.

This pivotal report is designed to serve as an indispensable resource for automotive original equipment manufacturers (OEMs), fuel system suppliers, material producers, and investors who are navigating the increasing complexities of vehicle lightweighting, emissions regulations, and evolving powertrain technologies. Vehicle plastic fuel tank systems are essential components for internal combustion engine (ICE) and hybrid vehicles, providing safe, efficient, and compliant storage for fuel while contributing to overall vehicle performance and design flexibility. This report provides a detailed, step-by-step understanding of the market's dynamics and its promising future trajectory.

Explore the Summary of the Full Research Report: https://www.marketresearchstore.com/market-insights/vehicle-plastic-fuel-tank-systems-market-829992

Market Definition

The Vehicle plastic fuel tank systems market report meticulously defines its core subject: vehicle plastic fuel tank systems. These systems primarily consist of fuel tanks manufactured from plastic materials, predominantly High-Density Polyethylene (HDPE), using processes like blow molding. Unlike traditional metal fuel tanks, plastic fuel tanks offer significant advantages such as lighter weight, greater design flexibility (allowing for more complex shapes to optimize space utilization), superior corrosion resistance, and improved safety performance in crash scenarios due to their ability to deform without rupturing. The complete system includes the tank itself, along with integrated components like fuel pumps, level sensors, fuel lines, and evaporative emission control systems (EVAP systems), all designed to meet stringent automotive safety and environmental regulations. The market encompasses the production and supply of these integrated systems for various vehicle types across the global automotive industry.

Key Highlights

The research report provides a granular, step-by-step examination of the vehicle plastic fuel tank systems market, delivering actionable insights for stakeholders.

Market Size and Growth: The report reveals a robust growth trajectory for the vehicle plastic fuel tank systems market, poised for significant expansion over the forecast period. This projected growth is driven by several factors, including sustained global automotive production, the continuous demand for lightweight vehicle components to improve fuel efficiency and reduce emissions, the increasing adoption of hybrid electric vehicles (HEVs) that still require fuel tanks, and the inherent advantages of plastic over metal in terms of design flexibility and cost-effectiveness. The data highlights a steady and resilient demand for these essential systems, reflecting evolving automotive industry standards and consumer preferences.

Consumer Preferences: A crucial aspect explored in the report is the shifting landscape of consumer preferences, particularly as they translate into vehicle design and performance. While consumers don't directly choose fuel tank materials, their demand for fuel-efficient vehicles indirectly drives the adoption of lightweight plastic fuel tanks. The increasing focus on vehicle safety and crashworthiness also favors plastic tanks due to their superior deformation characteristics. Furthermore, the growing popularity of SUVs and CUVs, which often benefit from the design flexibility offered by plastic tanks to maximize interior space, influences market demand. The overall trend towards lower emissions and environmental responsibility also pushes OEMs to adopt solutions that contribute to these goals.

Technological Innovations: The report dedicates a significant section to the technological innovations transforming the market. This includes advancements in multi-layer co-extrusion blow molding techniques, allowing for the integration of barrier layers (e.g., EVOH) to reduce hydrocarbon permeation and meet stricter evaporative emission standards. Innovations in lightweighting technologies, such as the use of composite materials and optimized structural designs, are further reducing the weight of plastic fuel tanks. The development of integrated fuel tank modules that combine multiple components (pump, sensors, lines) into a single unit is streamlining assembly and improving efficiency. Furthermore, research into sustainable materials, including recycled plastics and bio-based polymers, for fuel tank production is a notable trend, aligning with broader automotive sustainability goals.

Market Segmentation: The vehicle plastic fuel tank systems market report meticulously segments the market.

- By Material Type: This includes High-Density Polyethylene (HDPE), which is the most common, and other plastics/composites used for specialized applications.

- By Vehicle Type: Encompasses passenger vehicles, light commercial vehicles (LCVs), and heavy commercial vehicles (HCVs), each with specific design and volume requirements.

- By Sales Channel: Ranges across OEM (Original Equipment Manufacturer) and Aftermarket, indicating primary sales avenues.

- Dominating Regions: While the report delves into specific regional dominance within these segments, it highlights that Asia Pacific and Europe are prominent regions driving demand across various product types and vehicle categories due to their large automotive manufacturing bases and stringent emission regulations.

Regional Analysis: The report provides an exhaustive regional analysis, covering North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA). The Asia Pacific region is identified as the largest and fastest-growing market, primarily driven by its massive automotive production volumes, increasing vehicle sales, and the rapid adoption of advanced manufacturing technologies in countries like China, Japan, and India. Europe holds a significant market share, characterized by stringent emission regulations (e.g., Euro 6/7), a strong focus on lightweighting, and the presence of major automotive OEMs and fuel system suppliers.

North America also represents a substantial market, influenced by a large vehicle parc, the increasing popularity of SUVs and light trucks, and ongoing efforts to meet fuel economy standards. The report details the specific market drivers, regulatory environments, and growth opportunities within each geographical segment, offering invaluable insights for regional market entry and expansion strategies.

Competitive Landscape: The competitive landscape section identifies and profiles key players shaping the vehicle plastic fuel tank systems market. The report includes in-depth analyses of industry leaders such as Kautex Textron GmbH & Co. KG, Plastic Omnium, Magna International Inc., YAPP Automotive Systems Co. Ltd., TI Fluid Systems, Yachiyo Industry Co. Ltd., Inergy Automotive Systems, FTS Co. Ltd., Sakamoto Industry Co. Ltd., Martinrea International Inc., and Unipr. This section provides an overview of their product portfolios, market strategies, recent developments, and competitive strengths, offering a clear picture of the market's structure and the strategic moves of its participants.

Sustainability Trends: Sustainability is an increasingly important trend influencing the vehicle plastic fuel tank systems market. This includes a strong focus on lightweighting fuel tanks to reduce overall vehicle weight, thereby improving fuel efficiency and lowering CO2 emissions. Manufacturers are also emphasizing the use of recycled plastic content (PCR – Post-Consumer Recycled) in fuel tank production and exploring bio-based polymers to reduce reliance on virgin fossil-based materials. The design of fuel tanks for enhanced recyclability at the end-of-life of the vehicle is also gaining traction. Furthermore, advancements in evaporative emission control systems (EVAP) integrated into plastic tanks are crucial for meeting increasingly stringent environmental regulations regarding hydrocarbon emissions.

Challenges & Opportunities

The market for vehicle plastic fuel tank systems, while promising, is not without its challenges.

Challenges

- Transition to Electric Vehicles (EVs): The long-term shift towards battery electric vehicles (BEVs) poses a significant challenge as BEVs do not require traditional fuel tanks.

- Stringent Emission Regulations: Meeting increasingly strict evaporative emission standards (e.g., LEV III, Euro 7) requires continuous investment in advanced barrier technologies.

- Material Compatibility: Ensuring the long-term chemical compatibility of plastic materials with evolving fuel compositions (e.g., higher ethanol blends) is a constant challenge.

- Safety Standards: Adhering to rigorous global safety standards for fuel containment in crash scenarios.

- Competition from Alternative Materials: While plastic dominates, continuous innovation in metal tank technologies or alternative fuel storage could pose competition.

Opportunities

- Growth of Hybrid Electric Vehicles (HEVs): HEVs still require fuel tanks, and their increasing market share provides a significant opportunity for plastic fuel tank systems.

- Lightweighting Imperatives: The ongoing automotive industry drive to reduce vehicle weight for fuel efficiency and performance continues to favor plastic over metal tanks.

- Emerging Markets: Growth in vehicle production and sales in developing economies presents new opportunities for plastic fuel tank system adoption.

- Technological Advancements: Continuous innovation in multi-layer blow molding, barrier materials, and integrated systems enhances product performance and value.

- Sustainability Focus: Opportunities to develop and market fuel tanks with higher recycled content or bio-based materials, aligning with OEM and consumer sustainability goals.

Future Outlook

The future of the vehicle plastic fuel tank systems market appears robust and dynamic in the short to medium term. The report concludes that the market is poised for sustained growth, driven by the continued dominance of ICE and hybrid vehicles, the imperative for lightweighting, and ongoing technological advancements. The emphasis will increasingly be on developing highly efficient, lightweight, and environmentally compliant fuel tank systems that integrate seamlessly into complex vehicle architectures. While the long-term outlook will be influenced by the pace of EV adoption, the vehicle plastic fuel tank systems market will solidify its position as a critical and expanding sector essential for the evolution and performance of the global automotive industry.

About Us

Market Research Store is a single destination for all types of industries, global, and regional reports. We feature large repository of latest industry reports and market statistics published by reputed private publishers and public organizations. Market Research Store is the comprehensive collection of market intelligence products and services available. Our vast database of reports enables our clients to benefit from expert insights on global industries, products, and market trends.

Contact Us

Market Research Store

244 Fifth Avenue, Suite N202

New York, 10001, United States

Tel: +1-302-444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

Email: sales@marketresearchstore.com

Website: www.marketresearchstore.com