Engineering Plastics Alloy Market Size, Share, and Trends Analysis Report

CAGR :

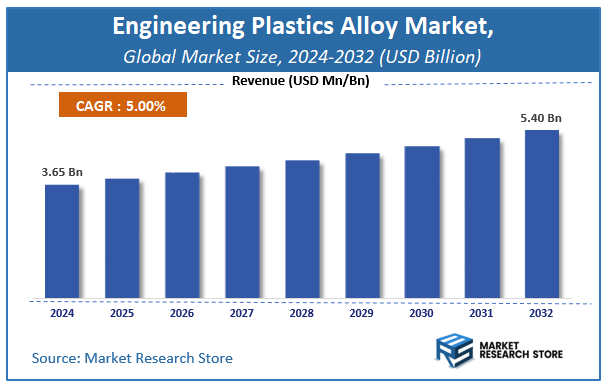

| Market Size 2024 (Base Year) | USD 3.65 Billion |

| Market Size 2032 (Forecast Year) | USD 5.40 Billion |

| CAGR | 5% |

| Forecast Period | 2025 - 2032 |

| Historical Period | 2020 - 2024 |

According to a recent study by Market Research Store, the global engineering plastics alloy market size was valued at approximately USD 3.65 Billion in 2024. The market is projected to grow significantly, reaching USD 5.40 Billion by 2032, growing at a compound annual growth rate (CAGR) of 5% during the forecast period from 2024 to 2032. The report highlights key growth drivers such as rising demand, technological advancements, and expanding applications. It also outlines potential challenges like regulatory changes and market competition, while emphasizing emerging opportunities for innovation and investment in the engineering plastics alloy industry.

Engineering Plastics Alloy Market: Overview

The growth of the engineering plastics alloy market is fueled by rising global demand across various industries and applications. The report highlights lucrative opportunities, analyzing cost structures, key segments, emerging trends, regional dynamics, and advancements by leading players to provide comprehensive market insights. The engineering plastics alloy market report offers a detailed industry analysis from 2024 to 2032, combining quantitative and qualitative insights. It examines key factors such as pricing, market penetration, GDP impact, industry dynamics, major players, consumer behavior, and socio-economic conditions. Structured into multiple sections, the report provides a comprehensive perspective on the market from all angles.

Key sections of the engineering plastics alloy market report include market segments, outlook, competitive landscape, and company profiles. Market Segments offer in-depth details based on Type, Application, and other relevant classifications to support strategic marketing initiatives. Market Outlook thoroughly analyzes market trends, growth drivers, restraints, opportunities, challenges, Porter’s Five Forces framework, macroeconomic factors, value chain analysis, and pricing trends shaping the market now and in the future. The Competitive Landscape and Company Profiles section highlights major players, their strategies, and market positioning to guide investment and business decisions. The report also identifies innovation trends, new business opportunities, and investment prospects for the forecast period.

Key Highlights:

- As per the analysis shared by our research analyst, the global engineering plastics alloy market is estimated to grow annually at a CAGR of around 5% over the forecast period (2025-2032).

- In terms of revenue, the global engineering plastics alloy market size was valued at around USD 3.65 Billion in 2024 and is projected to reach USD 5.40 Billion by 2032.

- The market is projected to grow at a significant rate due to Increasing demand for lightweight and high-performance materials from the automotive and electrical and electronics industries is a key driver. Growing adoption of engineering plastics alloys for their durability, cost-effectiveness, and resistance to hea.

- Based on the Type, the PE series alloys segment is growing at a high rate and will continue to dominate the global market as per industry projections.

- On the basis of Application, the The automotive industry. segment is anticipated to command the largest market share.

- Based on region, Asia Pacific is projected to dominate the global market during the forecast period.

Engineering Plastics Alloy Market: Report Scope

This report thoroughly analyzes the engineering plastics alloy market, exploring its historical trends, current state, and future projections. The market estimates presented result from a robust research methodology, incorporating primary research, secondary sources, and expert opinions. These estimates are influenced by the prevailing market dynamics as well as key economic, social, and political factors. Furthermore, the report considers the impact of regulations, government expenditures, and advancements in research and development on the market. Both positive and negative shifts are evaluated to ensure a comprehensive and accurate market outlook.

| Report Attributes | Report Details |

|---|---|

| Report Name | Engineering Plastics Alloy Market |

| Market Size in 2024 | USD 3.65 Billion |

| Market Forecast in 2032 | USD 5.40 Billion |

| Growth Rate | CAGR of 5% |

| Number of Pages | 215 |

| Key Companies Covered | BorgWarner, Bayer, DOW, TECHNOPOLYMER, BASF, GE, DOWN CHEM, LG Chem, CHIEL, KKPC, Plastics, Enichem, Dow Benelux, GeneralElectric Plastics |

| Segments Covered | By Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, The Middle East and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2020 to 2024 |

| Forecast Year | 2025 to 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Engineering Plastics Alloy Market: Dynamics

Key Growth Drivers :

The engineering plastics alloy market is primarily driven by the increasing demand for high-performance materials across diverse industries, notably automotive, electrical & electronics, and consumer goods. These alloys offer superior properties such as enhanced impact strength, heat resistance, chemical resistance, and dimensional stability compared to individual polymers, making them ideal for demanding applications. The automotive sector's continuous pursuit of lightweight materials to improve fuel efficiency and reduce emissions is a major catalyst for their adoption. Furthermore, the miniaturization and increased functionality of electronic devices, requiring materials with excellent electrical insulation and flame retardancy, significantly boost the demand for engineering plastics alloys, acting as a strong growth driver.

Restraints :

Despite the robust growth drivers, the engineering plastics alloy market faces several significant restraints. The relatively higher cost of engineering plastics alloys compared to commodity plastics can be a barrier, particularly for price-sensitive applications or smaller manufacturers. The complexity involved in designing and processing these alloys, often requiring specialized equipment and expertise to achieve desired properties, can limit their widespread adoption. Furthermore, the performance of these alloys can be sensitive to processing conditions, and inconsistencies can lead to variations in final product quality. Competition from other advanced materials like metals and composites, which may offer superior performance in certain niche applications, also acts as a restraint.

Opportunities :

The engineering plastics alloy market presents numerous opportunities for innovation and expansion. The increasing trend towards electrification in the automotive industry, including electric vehicles (EVs) and hybrid vehicles, creates demand for alloys with excellent thermal management, flame retardancy, and electrical insulation properties for battery components and charging infrastructure. The development of sustainable engineering plastics alloys incorporating recycled content or bio-based polymers can cater to the growing demand for eco-friendly materials. Furthermore, exploring new applications in rapidly expanding sectors such as medical devices, aerospace interiors, and industrial machinery, where high performance and durability are critical, offers significant growth avenues.

Challenges :

The engineering plastics alloy market is confronted by several key challenges. Achieving the optimal balance of properties from different polymers during the alloying process, while ensuring compatibility and processability, requires extensive research and development. The need to comply with stringent industry-specific regulations and certifications, particularly in automotive and aerospace, adds complexity and cost to product development. Managing the complex supply chain for various specialty polymers and additives, which can be subject to price volatility and availability issues, presents ongoing operational hurdles. Moreover, the long development cycles for new alloy formulations and their validation for specific applications can be a significant barrier to rapid market entry and expansion.

Engineering Plastics Alloy Market: Segmentation Insights

The global engineering plastics alloy market is segmented based on Type, Application, and Region. All the segments of the engineering plastics alloy market have been analyzed based on present & future trends and the market is estimated from 2024 to 2032.

Based on Type, the global engineering plastics alloy market is divided into PE series alloys, Polypropylene alloy series, PVC alloy series, Engineering plastics alloy series.

On the basis of Application, the global engineering plastics alloy market is bifurcated into The automotive industry., Mechanical industry, Electronic components.

Engineering Plastics Alloy Market: Regional Insights

The Asia-Pacific (APAC) region is the dominant and fastest-growing market for engineering plastics alloys, with China as its primary engine. This leadership is fueled by the region's vast manufacturing base, particularly in the automotive, consumer electronics, and appliance industries, which demand high-performance, lightweight materials. The rapid expansion of electric vehicle (EV) production in China, which relies heavily on engineering plastics for components to reduce weight and replace metal, is a key driver. While North America and Europe are mature markets focused on high-value, specialty alloys for aerospace and advanced electronics, APAC's unparalleled scale of manufacturing and its position as the "factory of the world" cement its dominant market share.

Engineering Plastics Alloy Market: Competitive Landscape

The engineering plastics alloy market report offers a thorough analysis of both established and emerging players within the market. It includes a detailed list of key companies, categorized based on the types of products they offer and other relevant factors. The report also highlights the market entry year for each player, providing further context for the research analysis.

The "Global Engineering Plastics Alloy Market" study offers valuable insights, focusing on the global market landscape, with an emphasis on major industry players such as;

- BorgWarner

- Bayer

- DOW

- TECHNOPOLYMER

- BASF

- GE

- DOWN CHEM

- LG Chem

- CHIEL

- KKPC

- Plastics

- Enichem

- Dow Benelux

- GeneralElectric Plastics

The Global Engineering Plastics Alloy Market is Segmented as Follows:

By Type

- PE series alloys

- Polypropylene alloy series

- PVC alloy series

- Engineering plastics alloy series

By Application

- The automotive industry.

- Mechanical industry

- Electronic components

By Region

- North America

- The U.S.

- Canada

- Mexico

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Australia

- South Korea

- Rest of Asia Pacific

- The Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- Kuwait

- South Africa

- Rest of the Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

Frequently Asked Questions

Table Of Content

Table of Content 1 Report Overview 1.1 Study Scope 1.2 Key Market Segments 1.3 Regulatory Scenario by Region/Country 1.4 Market Investment Scenario Strategic 1.5 Market Analysis by Type 1.5.1 Global Engineering Plastics Alloy Market Share by Type (2020-2026) 1.5.2 PE series alloys 1.5.3 Polypropylene alloy series 1.5.4 PVC alloy series 1.5.5 Engineering plastics alloy series 1.6 Market by Application 1.6.1 Global Engineering Plastics Alloy Market Share by Application (2020-2026) 1.6.2 The automotive industry. 1.6.3 Mechanical industry 1.6.4 Electronic components 1.7 Engineering Plastics Alloy Industry Development Trends under COVID-19 Outbreak 1.7.1 Global COVID-19 Status Overview 1.7.2 Influence of COVID-19 Outbreak on Engineering Plastics Alloy Industry Development 2. Global Market Growth Trends 2.1 Industry Trends 2.1.1 SWOT Analysis 2.1.2 Porter’s Five Forces Analysis 2.2 Potential Market and Growth Potential Analysis 2.3 Industry News and Policies by Regions 2.3.1 Industry News 2.3.2 Industry Policies 2.4 Industry Trends Under COVID-19 3 Value Chain of Engineering Plastics Alloy Market 3.1 Value Chain Status 3.2 Engineering Plastics Alloy Manufacturing Cost Structure Analysis 3.2.1 Production Process Analysis 3.2.2 Manufacturing Cost Structure of Engineering Plastics Alloy 3.2.3 Labor Cost of Engineering Plastics Alloy 3.2.3.1 Labor Cost of Engineering Plastics Alloy Under COVID-19 3.3 Sales and Marketing Model Analysis 3.4 Downstream Major Customer Analysis (by Region) 3.5 Value Chain Status Under COVID-19 4 Players Profiles 4.1 Dow Benelux 4.1.1 Dow Benelux Basic Information 4.1.2 Engineering Plastics Alloy Product Profiles, Application and Specification 4.1.3 Dow Benelux Engineering Plastics Alloy Market Performance (2015-2020) 4.1.4 Dow Benelux Business Overview 4.2 Plastics 4.2.1 Plastics Basic Information 4.2.2 Engineering Plastics Alloy Product Profiles, Application and Specification 4.2.3 Plastics Engineering Plastics Alloy Market Performance (2015-2020) 4.2.4 Plastics Business Overview 4.3 GeneralElectric Plastics 4.3.1 GeneralElectric Plastics Basic Information 4.3.2 Engineering Plastics Alloy Product Profiles, Application and Specification 4.3.3 GeneralElectric Plastics Engineering Plastics Alloy Market Performance (2015-2020) 4.3.4 GeneralElectric Plastics Business Overview 4.4 KKPC 4.4.1 KKPC Basic Information 4.4.2 Engineering Plastics Alloy Product Profiles, Application and Specification 4.4.3 KKPC Engineering Plastics Alloy Market Performance (2015-2020) 4.4.4 KKPC Business Overview 4.5 BASF 4.5.1 BASF Basic Information 4.5.2 Engineering Plastics Alloy Product Profiles, Application and Specification 4.5.3 BASF Engineering Plastics Alloy Market Performance (2015-2020) 4.5.4 BASF Business Overview 4.6 DOWN CHEM 4.6.1 DOWN CHEM Basic Information 4.6.2 Engineering Plastics Alloy Product Profiles, Application and Specification 4.6.3 DOWN CHEM Engineering Plastics Alloy Market Performance (2015-2020) 4.6.4 DOWN CHEM Business Overview 4.7 CHIEL 4.7.1 CHIEL Basic Information 4.7.2 Engineering Plastics Alloy Product Profiles, Application and Specification 4.7.3 CHIEL Engineering Plastics Alloy Market Performance (2015-2020) 4.7.4 CHIEL Business Overview 4.8 GE 4.8.1 GE Basic Information 4.8.2 Engineering Plastics Alloy Product Profiles, Application and Specification 4.8.3 GE Engineering Plastics Alloy Market Performance (2015-2020) 4.8.4 GE Business Overview 4.9 DOW 4.9.1 DOW Basic Information 4.9.2 Engineering Plastics Alloy Product Profiles, Application and Specification 4.9.3 DOW Engineering Plastics Alloy Market Performance (2015-2020) 4.9.4 DOW Business Overview 4.10 Bayer 4.10.1 Bayer Basic Information 4.10.2 Engineering Plastics Alloy Product Profiles, Application and Specification 4.10.3 Bayer Engineering Plastics Alloy Market Performance (2015-2020) 4.10.4 Bayer Business Overview 4.11 Enichem 4.11.1 Enichem Basic Information 4.11.2 Engineering Plastics Alloy Product Profiles, Application and Specification 4.11.3 Enichem Engineering Plastics Alloy Market Performance (2015-2020) 4.11.4 Enichem Business Overview 4.12 LG Chem 4.12.1 LG Chem Basic Information 4.12.2 Engineering Plastics Alloy Product Profiles, Application and Specification 4.12.3 LG Chem Engineering Plastics Alloy Market Performance (2015-2020) 4.12.4 LG Chem Business Overview 4.13 TECHNOPOLYMER 4.13.1 TECHNOPOLYMER Basic Information 4.13.2 Engineering Plastics Alloy Product Profiles, Application and Specification 4.13.3 TECHNOPOLYMER Engineering Plastics Alloy Market Performance (2015-2020) 4.13.4 TECHNOPOLYMER Business Overview 4.14 BorgWarner 4.14.1 BorgWarner Basic Information 4.14.2 Engineering Plastics Alloy Product Profiles, Application and Specification 4.14.3 BorgWarner Engineering Plastics Alloy Market Performance (2015-2020) 4.14.4 BorgWarner Business Overview 5 Global Engineering Plastics Alloy Market Analysis by Regions 5.1 Global Engineering Plastics Alloy Sales, Revenue and Market Share by Regions 5.1.1 Global Engineering Plastics Alloy Sales by Regions (2015-2020) 5.1.2 Global Engineering Plastics Alloy Revenue by Regions (2015-2020) 5.2 North America Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 5.3 Europe Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 5.4 Asia-Pacific Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 5.5 Middle East and Africa Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 5.6 South America Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 6 North America Engineering Plastics Alloy Market Analysis by Countries 6.1 North America Engineering Plastics Alloy Sales, Revenue and Market Share by Countries 6.1.1 North America Engineering Plastics Alloy Sales by Countries (2015-2020) 6.1.2 North America Engineering Plastics Alloy Revenue by Countries (2015-2020) 6.1.3 North America Engineering Plastics Alloy Market Under COVID-19 6.2 United States Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 6.2.1 United States Engineering Plastics Alloy Market Under COVID-19 6.3 Canada Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 6.4 Mexico Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 7 Europe Engineering Plastics Alloy Market Analysis by Countries 7.1 Europe Engineering Plastics Alloy Sales, Revenue and Market Share by Countries 7.1.1 Europe Engineering Plastics Alloy Sales by Countries (2015-2020) 7.1.2 Europe Engineering Plastics Alloy Revenue by Countries (2015-2020) 7.1.3 Europe Engineering Plastics Alloy Market Under COVID-19 7.2 Germany Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 7.2.1 Germany Engineering Plastics Alloy Market Under COVID-19 7.3 UK Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 7.3.1 UK Engineering Plastics Alloy Market Under COVID-19 7.4 France Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 7.4.1 France Engineering Plastics Alloy Market Under COVID-19 7.5 Italy Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 7.5.1 Italy Engineering Plastics Alloy Market Under COVID-19 7.6 Spain Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 7.6.1 Spain Engineering Plastics Alloy Market Under COVID-19 7.7 Russia Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 7.7.1 Russia Engineering Plastics Alloy Market Under COVID-19 8 Asia-Pacific Engineering Plastics Alloy Market Analysis by Countries 8.1 Asia-Pacific Engineering Plastics Alloy Sales, Revenue and Market Share by Countries 8.1.1 Asia-Pacific Engineering Plastics Alloy Sales by Countries (2015-2020) 8.1.2 Asia-Pacific Engineering Plastics Alloy Revenue by Countries (2015-2020) 8.1.3 Asia-Pacific Engineering Plastics Alloy Market Under COVID-19 8.2 China Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 8.2.1 China Engineering Plastics Alloy Market Under COVID-19 8.3 Japan Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 8.3.1 Japan Engineering Plastics Alloy Market Under COVID-19 8.4 South Korea Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 8.4.1 South Korea Engineering Plastics Alloy Market Under COVID-19 8.5 Australia Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 8.6 India Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 8.6.1 India Engineering Plastics Alloy Market Under COVID-19 8.7 Southeast Asia Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 8.7.1 Southeast Asia Engineering Plastics Alloy Market Under COVID-19 9 Middle East and Africa Engineering Plastics Alloy Market Analysis by Countries 9.1 Middle East and Africa Engineering Plastics Alloy Sales, Revenue and Market Share by Countries 9.1.1 Middle East and Africa Engineering Plastics Alloy Sales by Countries (2015-2020) 9.1.2 Middle East and Africa Engineering Plastics Alloy Revenue by Countries (2015-2020) 9.1.3 Middle East and Africa Engineering Plastics Alloy Market Under COVID-19 9.2 Saudi Arabia Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 9.3 UAE Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 9.4 Egypt Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 9.5 Nigeria Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 9.6 South Africa Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 10 South America Engineering Plastics Alloy Market Analysis by Countries 10.1 South America Engineering Plastics Alloy Sales, Revenue and Market Share by Countries 10.1.1 South America Engineering Plastics Alloy Sales by Countries (2015-2020) 10.1.2 South America Engineering Plastics Alloy Revenue by Countries (2015-2020) 10.1.3 South America Engineering Plastics Alloy Market Under COVID-19 10.2 Brazil Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 10.2.1 Brazil Engineering Plastics Alloy Market Under COVID-19 10.3 Argentina Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 10.4 Columbia Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 10.5 Chile Engineering Plastics Alloy Sales and Growth Rate (2015-2020) 11 Global Engineering Plastics Alloy Market Segment by Types 11.1 Global Engineering Plastics Alloy Sales, Revenue and Market Share by Types (2015-2020) 11.1.1 Global Engineering Plastics Alloy Sales and Market Share by Types (2015-2020) 11.1.2 Global Engineering Plastics Alloy Revenue and Market Share by Types (2015-2020) 11.2 PE series alloys Sales and Price (2015-2020) 11.3 Polypropylene alloy series Sales and Price (2015-2020) 11.4 PVC alloy series Sales and Price (2015-2020) 11.5 Engineering plastics alloy series Sales and Price (2015-2020) 12 Global Engineering Plastics Alloy Market Segment by Applications 12.1 Global Engineering Plastics Alloy Sales, Revenue and Market Share by Applications (2015-2020) 12.1.1 Global Engineering Plastics Alloy Sales and Market Share by Applications (2015-2020) 12.1.2 Global Engineering Plastics Alloy Revenue and Market Share by Applications (2015-2020) 12.2 The automotive industry. Sales, Revenue and Growth Rate (2015-2020) 12.3 Mechanical industry Sales, Revenue and Growth Rate (2015-2020) 12.4 Electronic components Sales, Revenue and Growth Rate (2015-2020) 13 Engineering Plastics Alloy Market Forecast by Regions (2020-2026) 13.1 Global Engineering Plastics Alloy Sales, Revenue and Growth Rate (2020-2026) 13.2 Engineering Plastics Alloy Market Forecast by Regions (2020-2026) 13.2.1 North America Engineering Plastics Alloy Market Forecast (2020-2026) 13.2.2 Europe Engineering Plastics Alloy Market Forecast (2020-2026) 13.2.3 Asia-Pacific Engineering Plastics Alloy Market Forecast (2020-2026) 13.2.4 Middle East and Africa Engineering Plastics Alloy Market Forecast (2020-2026) 13.2.5 South America Engineering Plastics Alloy Market Forecast (2020-2026) 13.3 Engineering Plastics Alloy Market Forecast by Types (2020-2026) 13.4 Engineering Plastics Alloy Market Forecast by Applications (2020-2026) 13.5 Engineering Plastics Alloy Market Forecast Under COVID-19 14 Appendix 14.1 Methodology 14.2 Research Data Source

Inquiry For Buying

Engineering Plastics Alloy

Request Sample

Engineering Plastics Alloy