Conductive Form-In-Place Gaskets Market Size, Share, and Trends Analysis Report

CAGR :

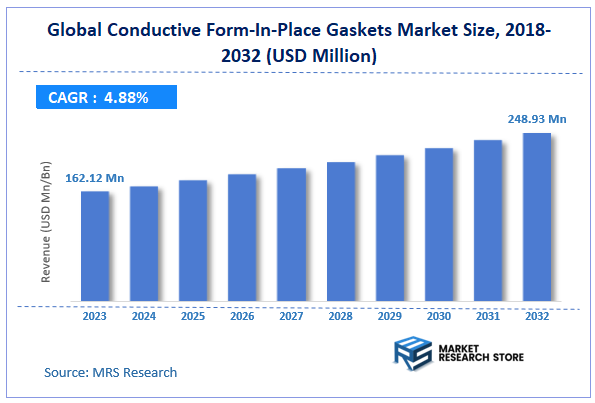

| Market Size 2023 (Base Year) | USD 162.12 Million |

| Market Size 2032 (Forecast Year) | USD 248.93 Million |

| CAGR | 4.88% |

| Forecast Period | 2024 - 2032 |

| Historical Period | 2018 - 2023 |

According to Market Research Store, the global conductive form-in-place gaskets market size was valued at around USD 162.12 million in 2023 and is estimated to reach USD 248.93 million by 2032, to register a CAGR of approximately 4.88% in terms of revenue during the forecast period 2024-2032.

To Get more Insights, Request a Free Sample

The conductive form-in-place gaskets report provides a comprehensive analysis of the market, including its size, share, growth trends, revenue details, and other crucial information regarding the target market. It also covers the drivers, restraints, opportunities, and challenges till 2032.

Global Conductive Form-In-Place Gaskets Market: Overview

Conductive Form-in-Place (FIP) gaskets are specialized materials used for creating electromagnetic interference (EMI) and radio frequency interference (RFI) shielding solutions in electronic devices. Made from conductive elastomers or silicones embedded with metallic particles, such as silver, nickel, or copper, these gaskets offer a reliable, flexible barrier to protect sensitive electronic components.

Their form-in-place application allows precise deposition directly onto device surfaces, enabling tailored sealing solutions for irregular shapes and compact designs, which is critical in industries like telecommunications, automotive, aerospace, and consumer electronics. This tailored approach optimizes the use of conductive material, minimizes waste, and ensures a consistent, high-performance seal that meets stringent industry standards.

Key Highlights

- The conductive form-in-place gaskets market is anticipated to grow at a CAGR of 4.88% during the forecast period.

- The global conductive form-in-place gaskets market was estimated to be worth approximately USD 162.12 million in 2023 and is projected to reach a value of USD 248.93 million by 2032.

- The growth of the conductive form-in-place gaskets market is being driven by the rising need for effective EMI shielding in compact, high-frequency electronic devices.

- Based on the type, the metal fillers segment is growing at a high rate and is projected to dominate the market.

- On the basis of application, the EMI shielding segment is projected to swipe the largest market share.

- By region, North America is expected to dominate the global market during the forecast period.

Conductive Form-In-Place Gaskets Market: Dynamics

Key Growth Drivers:

- Increasing demand for EMI/RFI shielding: The rising use of electronic devices across various industries necessitates effective shielding solutions to prevent electromagnetic interference (EMI) and radio frequency interference (RFI). Conductive FIP gaskets offer reliable and efficient shielding, driving market growth.

- Advancements in material technology: The development of innovative materials with superior electrical conductivity, thermal stability, and chemical resistance is expanding the application range of conductive FIP gaskets.

- Automation in manufacturing processes: The adoption of automated dispensing and curing techniques improves precision, reduces labor costs, and enhances overall production efficiency.

Restraints:

- High initial investment costs: The specialized equipment and materials required for FIP gasket manufacturing can be expensive, limiting market entry for smaller players.

- Complex application processes: The precise dispensing and curing of FIP gaskets demand technical expertise, which can be challenging for less experienced manufacturers.

Opportunities:

- Emerging applications in automotive and electronics: The increasing electrification and connectivity of vehicles and electronic devices create new opportunities for conductive FIP gaskets in sealing and shielding applications.

- Customization and tailored solutions: The ability to customize FIP gaskets to specific application requirements can drive market growth, especially in niche industries.

- Sustainability and eco-friendly materials: The demand for environmentally friendly products is growing, and the development of sustainable conductive FIP gasket materials can open up new markets.

Challenges:

- Stringent regulatory compliance: Adherence to safety and environmental regulations, such as RoHS and REACH, can increase production costs and complexity.

- Quality control and consistency: Maintaining consistent quality and performance across different batches of FIP gaskets is crucial, especially in critical applications.

Conductive Form-In-Place Gaskets Market: Segmentation Insights

The global conductive form-in-place gaskets market is divided by type, application, and region.

Segmentation Insights by Type

Based on type, the global conductive form-in-place gaskets market is divided into metal fillers, and metallic/non-metallic mixed fillers.

In the conductive form-in-place gaskets market, Metal Fillers lead as the most dominant segment. These gaskets typically incorporate metal particles, like silver, nickel, or copper, which offer superior conductivity and electromagnetic interference (EMI) shielding.

Metal fillers are valued for their high durability and reliable conductivity, essential in applications such as automotive electronics, aerospace, and telecommunications where precise EMI shielding and grounding are required. Their robustness makes them ideal for demanding environments where gaskets must withstand temperature fluctuations, vibrations, and exposure to harsh elements, thereby providing long-lasting performance in high-stakes applications.

The Metallic/Non-metallic Mixed Fillers segment follows closely, combining both metallic and non-metallic particles like elastomers, silicones, or other polymers with metal fillers. This blend provides a balance between conductivity and flexibility, making it suitable for applications where a softer, more adaptable seal is needed without compromising on EMI shielding.

Mixed fillers are particularly useful in consumer electronics and medical devices, where tight, intricate enclosures demand both effective sealing and sufficient conductivity. This segment is growing as industries prioritize miniaturization and intricate designs, benefiting from the unique properties of these mixed filler gaskets to achieve high-performance sealing and EMI protection in complex layouts.

Segmentation Insights by Application

On the basis of application, the global conductive form-in-place gaskets market is bifurcated into EMI shielding, electromagnetic compatibility, and other.

In the conductive form-in-place gaskets market, EMI Shielding emerges as the most dominant application. EMI shielding gaskets are essential in preventing electromagnetic interference from disrupting sensitive electronic components in various sectors, including telecommunications, aerospace, and automotive.

These gaskets offer a high level of protection by ensuring reliable contact between components, maintaining signal integrity, and reducing the risk of data corruption. The demand for EMI shielding gaskets is driven by the rapid growth in advanced electronics and increased regulatory requirements to control EMI emissions, particularly in high-density electronic environments.

The Electromagnetic Compatibility (EMC) segment is also significant, as it ensures that electronic devices can operate harmoniously in close proximity without interference. EMC gaskets help achieve compliance with industry standards, especially in sectors like medical devices, automotive, and consumer electronics. These gaskets are designed to minimize the impact of electronic emissions while improving device reliability and performance.

As more devices incorporate wireless connectivity, the need for EMC solutions has surged, driving adoption in this segment.

Conductive Form-In-Place Gaskets Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Conductive Form-In-Place Gaskets Market |

| Market Size in 2023 | USD 162.12 Million |

| USD 248.93 Million | |

| Growth Rate | CAGR of 4.88% |

| Number of Pages | 220 |

| Key Companies Covered | Parker Chomerics, Nolato, Laird, Dymax Corporation, CHT UK Bridgwater, Nystein, Permabond, Dow, Wacker Chemie, DAFA Polska, MAJR Products, EMI-tec, ThreeBond Group, DELO, and others. |

| Segments Covered | By Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Conductive Form-In-Place Gaskets Market: Regional Insights

- North America is expected to dominate the global market

North America leads the global market for conductive FIP gaskets, thanks to its strong base of aerospace, defense, and telecommunications industries. The region's emphasis on electromagnetic compatibility (EMC) standards and advancements in electronic device miniaturization bolster the demand for FIP gaskets. Companies in the U.S. especially drive innovation, prioritizing gaskets that offer high conductivity and reliability in demanding applications, further supporting North America’s lead in this market.

Asia-Pacific follows closely, propelled by its rapidly expanding consumer electronics, automotive, and telecommunications sectors. Countries like China, Japan, and South Korea are significant players, with high production volumes of consumer devices that require advanced shielding solutions. Additionally, the region's large-scale electronics manufacturing and the growth of 5G infrastructure contribute significantly to the demand for conductive FIP gaskets.

Europe is another vital region, with demand driven by the automotive and telecommunications industries, especially in Germany, the UK, and France. The region has strict regulatory requirements for EMC compliance, which encourages companies to adopt FIP gaskets in their products. European industries place high importance on reliable shielding solutions, particularly as the region invests heavily in electric vehicle (EV) technologies that often rely on these gaskets for effective electromagnetic interference (EMI) shielding.

Latin America experiences moderate growth in the conductive FIP gaskets market, with demand primarily centered around automotive and telecommunications applications. Brazil and Mexico are key markets, especially as automotive manufacturing grows in these countries. Although the market is smaller compared to North America and Asia-Pacific, the region’s developing technology infrastructure and increasing consumer electronics market present a growth opportunity for FIP gasket manufacturers.

The Middle East & Africa have a comparatively lower market share, with limited demand for conductive FIP gaskets. However, growth in telecommunications infrastructure, particularly in the UAE and South Africa, has led to a gradual increase in demand for these gaskets. The expansion of telecommunications networks and investment in electronics manufacturing is expected to drive demand, albeit at a slower rate compared to other regions.

Conductive Form-In-Place Gaskets Market: Competitive Landscape

The report provides an in-depth analysis of companies operating in the conductive form-in-place gaskets market, including their geographic presence, business strategies, product offerings, market share, and recent developments. This analysis helps to understand market competition.

Some of the major players in the global conductive form-in-place gaskets market include:

- Parker Chomerics

- Nolato

- Laird

- Dymax Corporation

- CHT UK Bridgwater

- Nystein

- Permabond

- Dow

- Wacker Chemie

- DAFA Polska

- MAJR Products

- EMI-tec

- ThreeBond Group

- DELO

The global conductive form-in-place gaskets market is segmented as follows:

By Type

- Metal Fillers

- Metallic/Non-metallic Mixed Fillers

By Application

- EMI Shielding

- Electromagnetic Compatibility

- Other

By Region

- North America

- U.S.

- Canada

- Europe

- U.K.

- France

- Germany

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia Pacific

- Latin America

- Brazil

- Rest of Latin America

- The Middle East and Africa

- GCC Countries

- South Africa

- Rest of Middle East Africa

Frequently Asked Questions

Based on statistics from the Market Research Store, the global conductive form-in-place gaskets market size was projected at approximately US$ 162.12 million in 2023. Projections indicate that the market is expected to reach around US$ 248.93 million in revenue by 2032.

The global conductive form-in-place gaskets market is expected to grow at a Compound Annual Growth Rate (CAGR) of around 4.88% during the forecast period from 2024 to 2032.

North America is expected to dominate the global conductive form-in-place gaskets market.

The global conductive form-in-place gaskets market is driven by the growing demand for EMI and RFI shielding in compact, high-frequency electronic devices, advancements in miniaturized electronics, and stringent regulatory standards for interference protection, particularly in the telecommunications, automotive, and consumer electronics sectors.

Some of the prominent players operating in the global conductive form-in-place gaskets market are; Parker Chomerics, Nolato, Laird, Dymax Corporation, CHT UK Bridgwater, Nystein, Permabond, Dow, Wacker Chemie, DAFA Polska, MAJR Products, EMI-tec, ThreeBond Group, DELO, and others.

Table Of Content

Inquiry For Buying

Conductive Form-In-Place Gaskets

Request Sample

Conductive Form-In-Place Gaskets