Non-metal 3D Printer Market Size, Share, and Trends Analysis Report

CAGR :

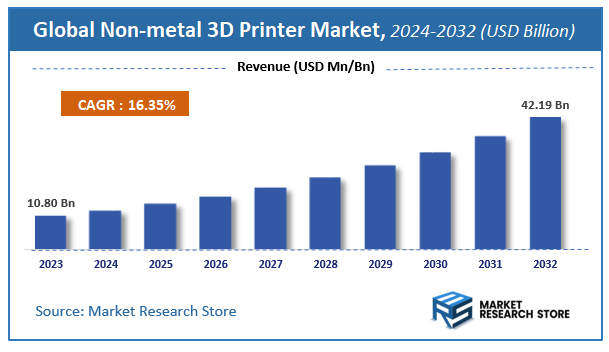

| Market Size 2023 (Base Year) | USD 10.80 Billion |

| Market Size 2032 (Forecast Year) | USD 42.19 Billion |

| CAGR | 16.35% |

| Forecast Period | 2024 - 2032 |

| Historical Period | 2018 - 2023 |

Non-metal 3D Printer Market Insights

According to Market Research Store, the global non-metal 3D printer market size was valued at around USD 10.80 billion in 2023 and is estimated to reach USD 42.19 billion by 2032, to register a CAGR of approximately 16.35% in terms of revenue during the forecast period 2024-2032.

The non-metal 3D printer report provides a comprehensive analysis of the market, including its size, share, growth trends, revenue details, and other crucial information regarding the target market. It also covers the drivers, restraints, opportunities, and challenges till 2032.

To Get more Insights, Request a Free Sample

Global Non-metal 3D Printer Market: Overview

A Non-metal 3D Printer is a type of 3D printing technology specifically designed to create objects using non-metallic materials such as plastics, resins, ceramics, composites, and biomaterials. These printers utilize techniques like Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) to build layer-by-layer structures. Non-metal 3D printers are widely used in industries like healthcare (for prosthetics and dental models), education, automotive, consumer goods, and prototyping due to their versatility, cost-effectiveness, and ability to produce complex geometries.

The Non-metal 3D Printer market is growing rapidly, driven by increasing adoption across industries for prototyping, customization, and small-scale production. The healthcare sector, in particular, is a major contributor, with applications in medical devices, dental implants, and tissue engineering. Advances in materials, such as biodegradable plastics and high-performance resins, are expanding the scope of non-metal 3D printing. Additionally, the rise of affordable desktop 3D printers has made the technology accessible to small businesses and hobbyists. However, challenges like limited material options for high-strength applications and slower production speeds compared to traditional manufacturing methods persist.

Key Highlights

- The non-metal 3D printer market is anticipated to grow at a CAGR of 16.35% during the forecast period.

- The global non-metal 3D printer market was estimated to be worth approximately USD 10.80 billion in 2023 and is projected to reach a value of USD 42.19 billion by 2032.

- The growth of the non-metal 3D printer market is being driven by several key factors, including the increasing demand for customized and personalized products, the growing adoption of additive manufacturing across various industries, and the advancements in 3D printing technologies.

- Based on the type, the fused deposition modeling (FDM) segment is growing at a high rate and is projected to dominate the market.

- On the basis of material, the plastic segment is projected to swipe the largest market share.

- In terms of application, the prototyping segment is expected to dominate the market.

- Based on the end-user industry, the automotive segment is expected to dominate the market.

- Based on the technology, the laser-based technologies segment is expected to dominate the market.

- By region, North America is expected to dominate the global market during the forecast period.

Non-metal 3D Printer Market: Dynamics

Key Drivers

- Rapid Prototyping: 3D printing with non-metallic materials like plastics (PLA, ABS, nylon) enables rapid prototyping of designs, allowing for quick iterations and faster product development cycles across various industries.

- Customization and Personalization: 3D printing facilitates the production of highly customized and personalized products, catering to individual needs and preferences.

- Lightweighting and Design Freedom: Non-metallic 3D printing enables the creation of complex geometries and lightweight structures that are difficult or impossible to manufacture using traditional methods.

- On-Demand Manufacturing: 3D printing allows for on-demand manufacturing, reducing inventory costs and enabling localized production, improving supply chain efficiency.

Restraints

- Material Limitations: Limitations in the mechanical properties and availability of certain non-metallic 3D printing materials can restrict their use in some applications.

- Build Time and Cost: 3D printing can be time-consuming for complex parts, and the cost of materials and post-processing can sometimes be higher compared to traditional manufacturing methods.

- Surface Finish: Achieving a high-quality surface finish can be challenging with some 3D printing technologies, requiring additional post-processing steps.

- Intellectual Property Concerns: Protecting intellectual property rights related to 3D-printed designs can be complex.

Opportunities

- Material Innovation: Development of new and improved 3D printing materials with enhanced properties, such as higher strength, better heat resistance, and improved biocompatibility.

- Integration with AI and IoT: Integration of AI and IoT technologies to optimize 3D printing processes, improve part quality, and enable remote monitoring and control.

- Exploring New Applications: Exploring new and emerging applications for non-metallic 3D printing, such as in healthcare, aerospace, and the automotive industry.

- Focus on Sustainability: Emphasizing sustainability throughout the 3D printing process, including the use of recycled materials and the development of more energy-efficient 3D printers.

Challenges

- Maintaining Product Quality and Consistency: Ensuring consistent quality and reliability of 3D-printed parts across different production runs.

- Addressing Environmental Concerns: Mitigating the environmental impact of 3D printing, including material waste, energy consumption, and the disposal of 3D printing materials.

- Staying Competitive: Remaining competitive in a dynamic market with increasing competition from other 3D printing technologies and manufacturers.

- Meeting Evolving Regulatory Requirements: Complying with evolving safety and environmental regulations related to 3D printing materials and processes.

Non-metal 3D Printer Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Non-metal 3D Printer Market |

| Market Size in 2023 | USD 10.80 Billion |

| Market Forecast in 2032 | USD 42.19 Billion |

| Growth Rate | CAGR of 16.35% |

| Number of Pages | 140 |

| Key Companies Covered | Stratasys, EOS, GE, 3D Systems, HP, SLM Solutions, EnvisionTEC, Renishaw, ExOne, Optomec, SHINING 3D, VoxelJet AG, BLT, Sciaky Inc, UnionTech |

| Segments Covered | By Product Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2023 |

| Forecast Year | 2024 to 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Non-metal 3D Printer Market: Segmentation Insights

The global non-metal 3D printer market is divided by type, material, application, end-user industry, technology, and region.

Segmentation Insights by Type

Based on type, the global non-metal 3D printer market is divided into fused deposition modeling (FDM), stereolithography (SLA), SLA-based resin printers, selective laser sintering (SLS), and multi jet fusion (MJF).

The Fused Deposition Modeling (FDM) segment dominates the Non-metal 3D Printer Market due to its widespread adoption, cost-effectiveness, and ease of use. FDM technology is extensively used in prototyping, product development, and small-scale manufacturing across industries such as consumer goods, education, and healthcare. Its affordability, material versatility, and user-friendly operation make it the most accessible 3D printing method, driving its market leadership.

The Stereolithography (SLA) segment holds a significant share, particularly in applications requiring high precision and fine detail, such as dental, jewelry, and medical device manufacturing. SLA-based Resin Printers further contribute to this segment by offering high-resolution prints with smooth surfaces, making them ideal for intricate designs and custom applications.

The Selective Laser Sintering (SLS) segment is gaining traction, particularly in industrial applications that require strong, durable, and complex parts. SLS technology is preferred in sectors such as aerospace, automotive, and medical for functional prototyping and low-volume production.

The Multi Jet Fusion (MJF) segment is expanding rapidly due to its ability to produce high-strength, high-detail parts with fast printing speeds. It is increasingly adopted in industrial and commercial applications, particularly for customized manufacturing and end-use production.

Segmentation Insights by Material

On the basis of material, the global non-metal 3D printer market is bifurcated into plastic, resin, composites, ceramics, and others.

The Plastic segment dominates the Non-metal 3D Printer Market due to its extensive use in prototyping, product design, and educational applications. Plastics such as PLA, ABS, and PETG are widely utilized in Fused Deposition Modeling (FDM) printers, which are the most common and affordable type of non-metal 3D printers. The versatility, ease of printing, and cost-effectiveness of plastic materials contribute to their leading market position.

The Resin segment holds a significant share, particularly in Stereolithography (SLA) and SLA-based resin printers, which require photopolymer resins to create high-precision, smooth-finish parts. Resin-based printing is preferred in industries such as dental, jewelry, and medical devices due to its ability to produce intricate details and customized components.

The Composites segment is growing, driven by demand for enhanced material properties such as increased strength, durability, and temperature resistance. Composite materials, including carbon fiber-reinforced and glass fiber-reinforced polymers, are used in applications requiring higher mechanical performance, such as aerospace, automotive, and industrial manufacturing.

The Ceramics segment, though niche, is expanding in specialized industries such as healthcare, electronics, and high-temperature applications. Ceramic 3D printing is particularly valuable for biomedical implants, dental restorations, and advanced industrial components due to its superior thermal resistance and biocompatibility.

Segmentation Insights by Application

On the basis of application, the global non-metal 3D printer market is bifurcated into prototyping, manufacturing, tooling, construction, and aerospace and defense.

The Prototyping segment dominates the Non-metal 3D Printer Market, driven by its extensive use across industries such as automotive, consumer goods, and electronics. Companies rely on Fused Deposition Modeling (FDM) and Stereolithography (SLA) technologies to create rapid prototypes that accelerate product development cycles. The cost-effectiveness, material versatility, and ability to produce functional prototypes with intricate designs contribute to the segment’s leadership.

The Manufacturing segment is growing significantly, especially with the adoption of Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF) for end-use parts production. Industries such as healthcare, aerospace, and automotive are leveraging non-metal 3D printing for customized components, lightweight structures, and low-volume manufacturing runs. The shift toward on-demand production and reduced material waste further strengthens the adoption of 3D printing in manufacturing.

The Tooling segment is gaining traction as industries incorporate 3D printing for jigs, fixtures, and molds, reducing lead times and costs compared to traditional machining. Composite and high-strength plastic materials are increasingly used in the tooling sector due to their durability and performance advantages.

The Construction segment is emerging, with non-metal 3D printing technologies being explored for architectural modeling, interior design elements, and sustainable building materials. While still in its early stages, advancements in large-scale 3D printing for construction applications are expected to contribute to market growth.

The Aerospace and Defense segment represents a key growth area, utilizing non-metal 3D printing for lightweight components, UAV parts, and customized defense equipment. The demand for high-performance materials such as composites and ceramics is particularly strong in this sector, driven by the need for enhanced strength-to-weight ratios and precision engineering.

Segmentation Insights by End-User Industry

On the basis of end-user industry, the global non-metal 3D printer market is bifurcated into automotive, aerospace, healthcare, consumer goods, and industrial.

The Automotive segment dominates the Non-metal 3D Printer Market, driven by its extensive use in prototyping, tooling, and end-use part production. Automakers leverage Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) technologies to create rapid prototypes, lightweight structural components, and customized interior parts. The growing demand for cost-effective and time-efficient design iterations further strengthens 3D printing adoption in the automotive sector.

The Aerospace segment is experiencing rapid growth, utilizing Multi Jet Fusion (MJF) and SLS for producing lightweight, high-performance components. The aerospace industry prioritizes weight reduction, fuel efficiency, and complex geometries, making 3D printing an ideal manufacturing solution for customized UAV parts, brackets, and composite structures.

The Healthcare segment is expanding significantly, with non-metal 3D printing being widely used for prosthetics, implants, surgical guides, and dental applications. The ability to create patient-specific medical devices using biocompatible materials has led to increased adoption of resin and composite-based 3D printing technologies in healthcare.

The Consumer Goods segment is growing steadily, benefiting from 3D printing's ability to produce custom-designed accessories, eyewear, footwear, and home décor products. Companies use 3D printing to enable mass customization, rapid product development, and sustainable manufacturing practices in response to changing consumer demands.

The Industrial segment is leveraging non-metal 3D printing for tooling, jigs, and functional prototypes across various manufacturing applications. Industries such as electronics and packaging use ceramic and composite-based 3D printing to develop durable and high-precision components. The adoption of on-demand production and decentralized manufacturing further propels growth in this sector.

Segmentation Insights by Technology

On the basis of technology, the global non-metal 3D printer market is bifurcated into laser-based technologies, inkjet printing, binder jetting, extrusion-based printing, and others.

The Laser-based Technologies segment dominates the Non-metal 3D Printer Market due to its precision, speed, and ability to process a wide range of materials, including ceramics, composites, and resins. Selective Laser Sintering (SLS) and Stereolithography (SLA) are widely used for high-performance applications in industries such as aerospace, healthcare, and automotive, where complex geometries and durability are critical. The increasing adoption of laser-based methods for industrial prototyping and end-use part manufacturing further strengthens its market position.

The Inkjet Printing segment is experiencing significant growth, particularly in applications requiring high-resolution and multi-material printing. This technology is widely used in healthcare for bioprinting, dental applications, and creating intricate medical models. Additionally, the ability to print colorized and texture-rich components makes inkjet 3D printing valuable for consumer goods and design applications.

The Binder Jetting segment is gaining traction due to its cost-effectiveness and capability to produce large-scale, complex structures without requiring support materials. Industries such as construction, aerospace, and tooling benefit from binder jetting’s ability to create lightweight, durable parts with enhanced mechanical properties. The technology’s suitability for ceramic and sand-based applications is also expanding its market presence.

The Extrusion-based Printing segment, including Fused Deposition Modeling (FDM), remains a widely used and accessible technology, particularly in consumer goods and educational applications. Its affordability, ease of use, and compatibility with a variety of non-metal materials, including bioplastics and composites, contribute to its steady market share. This technology is also expanding in industrial settings for rapid prototyping and functional testing.

Non-metal 3D Printer Market: Regional Insights

- North America is expected to dominates the global market

North America is a dominant region in the Non-metal 3D Printer market, led by the United States and Canada. The region benefits from strong research and development activities, a well-established additive manufacturing industry, and high adoption across medical, aerospace, and consumer goods sectors. The presence of leading 3D printer manufacturers, along with government initiatives supporting digital manufacturing, further strengthens market growth. The healthcare sector in this region extensively uses non-metal 3D printing for prosthetics, dental implants, and medical devices, fueling demand.

Europe is another significant market, driven by strong industrial adoption in Germany, the UK, and France. The region’s advanced manufacturing sector, combined with strict environmental regulations, promotes the use of sustainable and recyclable non-metal materials in 3D printing. The automotive and aerospace industries in Europe increasingly rely on non-metal 3D printing for producing lightweight components. Additionally, research institutions and universities actively contribute to the advancement of non-metal 3D printing technologies.

Asia Pacific region is experiencing the fastest growth in the Non-metal 3D Printer market, led by China, Japan, South Korea, and India. The rise in consumer electronics and manufacturing industries, along with increasing government support for additive manufacturing, is driving market expansion. China, in particular, is a key player due to its strong manufacturing ecosystem and investments in 3D printing technology. The growing demand for customized consumer products, coupled with advancements in ceramic and polymer-based 3D printing, is further propelling growth in this region.

Latin America market is gradually expanding, with Brazil and Mexico being the key contributors. The adoption of non-metal 3D printing is increasing in industries such as healthcare, education, and small-scale manufacturing. However, the market still faces challenges such as high costs of 3D printing technology and limited technical expertise, which may slow down widespread adoption.

Middle East & Africa market is developing steadily, with the UAE and South Africa emerging as key markets. The adoption of 3D printing technology in construction, healthcare, and consumer goods is gaining traction. Government initiatives in the UAE to promote additive manufacturing, particularly in construction using non-metal materials, are expected to drive market growth in this region. However, infrastructure limitations and high initial investment costs continue to pose challenges in some areas.

Non-metal 3D Printer Market: Competitive Landscape

The report provides an in-depth analysis of companies operating in the non-metal 3D printer market, including their geographic presence, business strategies, product offerings, market share, and recent developments. This analysis helps to understand market competition.

Some of the major players in the global non-metal 3D printer market include:

- 3D Systems

- BLT

- EnvisionTEC

- EOS

- ExOne

- GE

- HP

- Optomec

- Renishaw

- Sciaky Inc

- SHINING 3D

- SLM Solutions

- Stratasys

- UnionTech

- VoxelJet AG

The global non-metal 3D printer market is segmented as follows:

By Type

- Fused Deposition Modeling (FDM)

- Stereolithography (SLA)

- SLA-based Resin Printers

- Selective Laser Sintering (SLS)

- Multi Jet Fusion (MJF)

By Material

- Plastic

- Resin

- Composites

- Ceramics

- Others

By Application

- Prototyping

- Manufacturing

- Tooling

- Construction

- Aerospace and Defense

By End-User Industry

- Automotive

- Aerospace

- Healthcare

- Consumer Goods

- Industrial

By Technology

- Laser-based Technologies

- Inkjet Printing

- Binder Jetting

- Extrusion-based Printing

- Others

By Region

- North America

- U.S.

- Canada

- Europe

- U.K.

- France

- Germany

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia Pacific

- Latin America

- Brazil

- Rest of Latin America

- The Middle East and Africa

- GCC Countries

- South Africa

- Rest of Middle East Africa

Frequently Asked Questions

Based on statistics from the Market Research Store, the global non-metal 3D printer market size was projected at approximately US$ 10.80 billion in 2023. Projections indicate that the market is expected to reach around US$ 42.19 billion in revenue by 2032.

The global non-metal 3D printer market is expected to grow at a Compound Annual Growth Rate (CAGR) of around 16.35% during the forecast period from 2024 to 2032.

North America is expected to dominate the global non-metal 3D printer market.

The global non-metal 3D printer market is driven by factors such as the increasing demand for customized and complex parts, the growing adoption of additive manufacturing in various industries, and advancements in non-metal 3D printing technologies.

Some of the prominent players operating in the global non-metal 3D printer market are; 3D Systems, BLT, EnvisionTEC, EOS, ExOne, GE, HP, Optomec, Renishaw, Sciaky Inc , SHINING 3D, SLM Solutions, Stratasys, UnionTech, VoxelJet AG, and others.

The global non-metal 3D printer market report provides a comprehensive analysis of market definitions, growth factors, opportunities, challenges, geographic trends, and competitive dynamics.

Table Of Content

Inquiry For Buying

Non-metal 3D Printer

Request Sample

Non-metal 3D Printer